Elastic body of load cell and weighing system

A technology of load cells and elastomers, applied in the field of weighing, can solve problems such as damage to elastomers and inability to accurately weigh, and achieve the effect of auxiliary support for measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

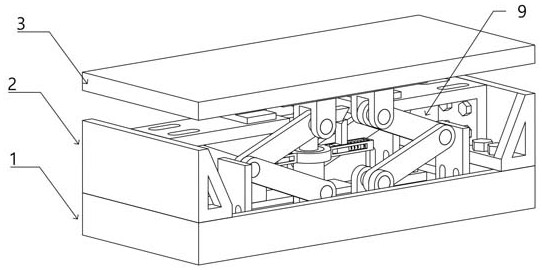

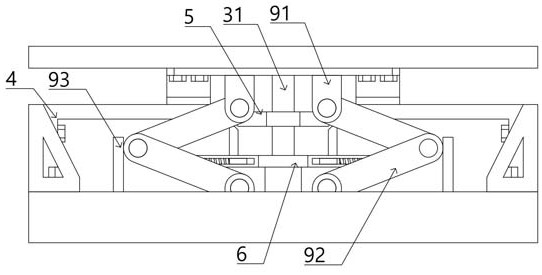

[0022] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0023] An elastic body of a load cell, comprising a base 1, a vertical plate 2, an action frame 3, a cantilevered elastic plate 4, a pressure plate 5, a guide rail 6, a support frame 7, a spring 8 and an auxiliary deformation component 9, wherein:

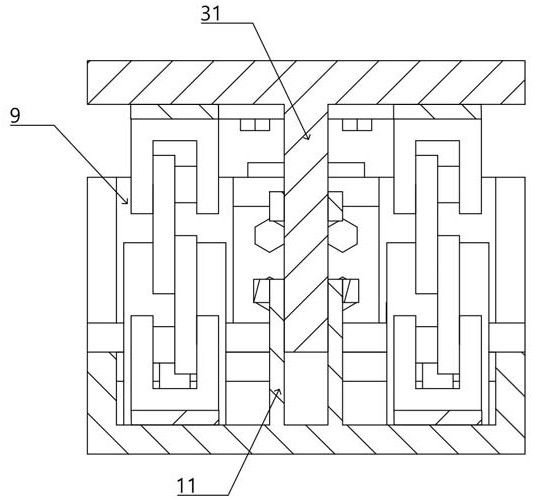

[0024] The vertical plate 2 is arranged on the base 1, the bottom of the base 1 is provided with a sleeve 11, and the bottom of the action frame 3 is provided with a support rod 31, wherein the support rod 31 fits in the sleeve 11, and then the action frame 3 is formed in the vertical direction. mobile vice;

[0025] The cantilever elastic plate 4 is connected with the vertical plate 2, and the action block at the bottom of the action frame 3 is in contact with the end of the cantilever elastic plate 4, and then when the action frame 3 moves down, the cantilever elastic plate 4 is elastically deformed, and the pressing plate 5 is fixed. Set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com