An inner core part of a lock and a handle door lock using the inner core part of the lock

An inner core and bottom plate technology, applied in building locks, handle connections, door/window accessories, etc., can solve the problems of prolongation, insufficient tension, adverse service life, etc., and achieve reduction in elastic deformation, increase in tension, and increase in use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

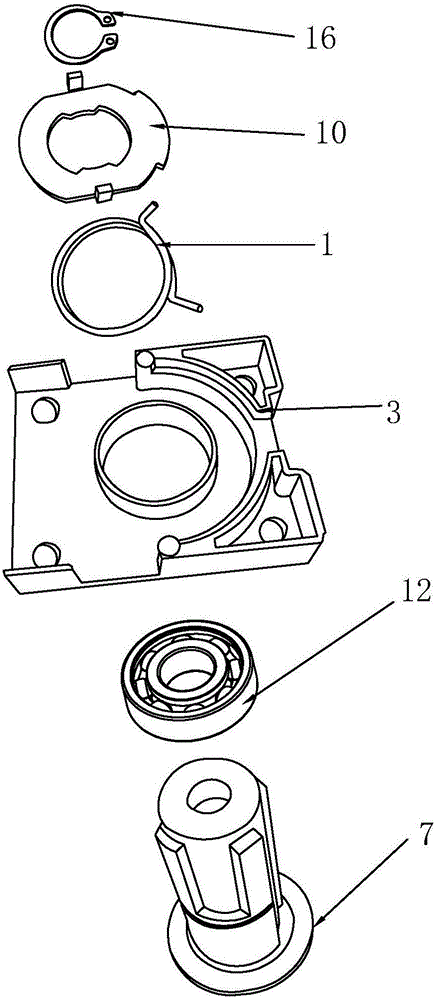

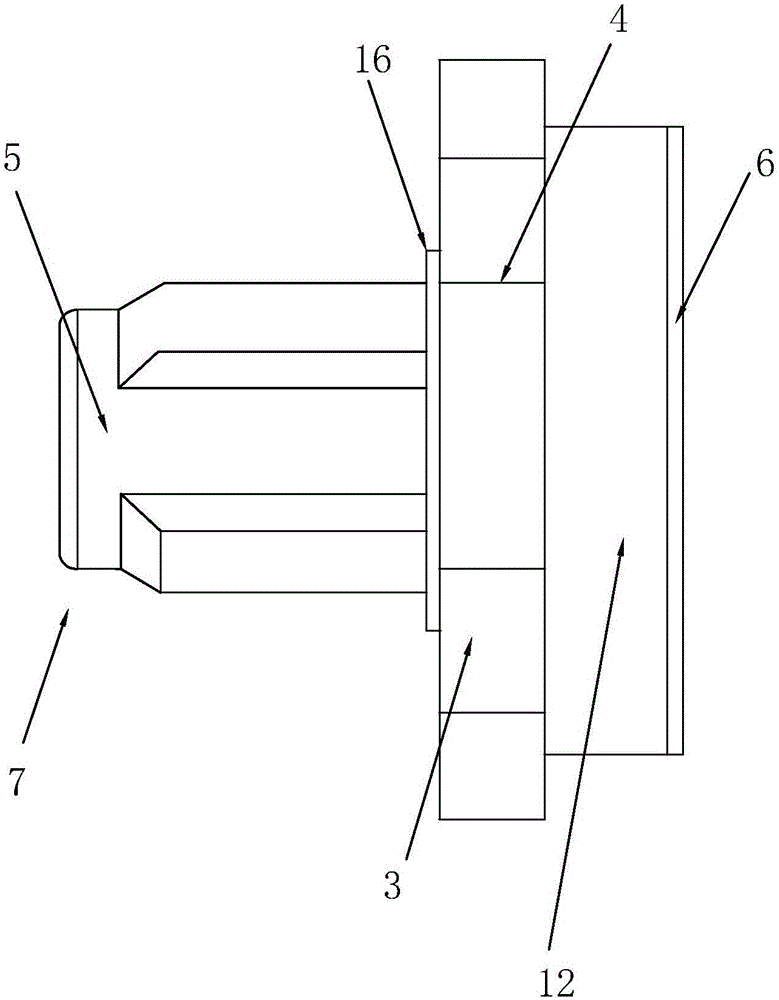

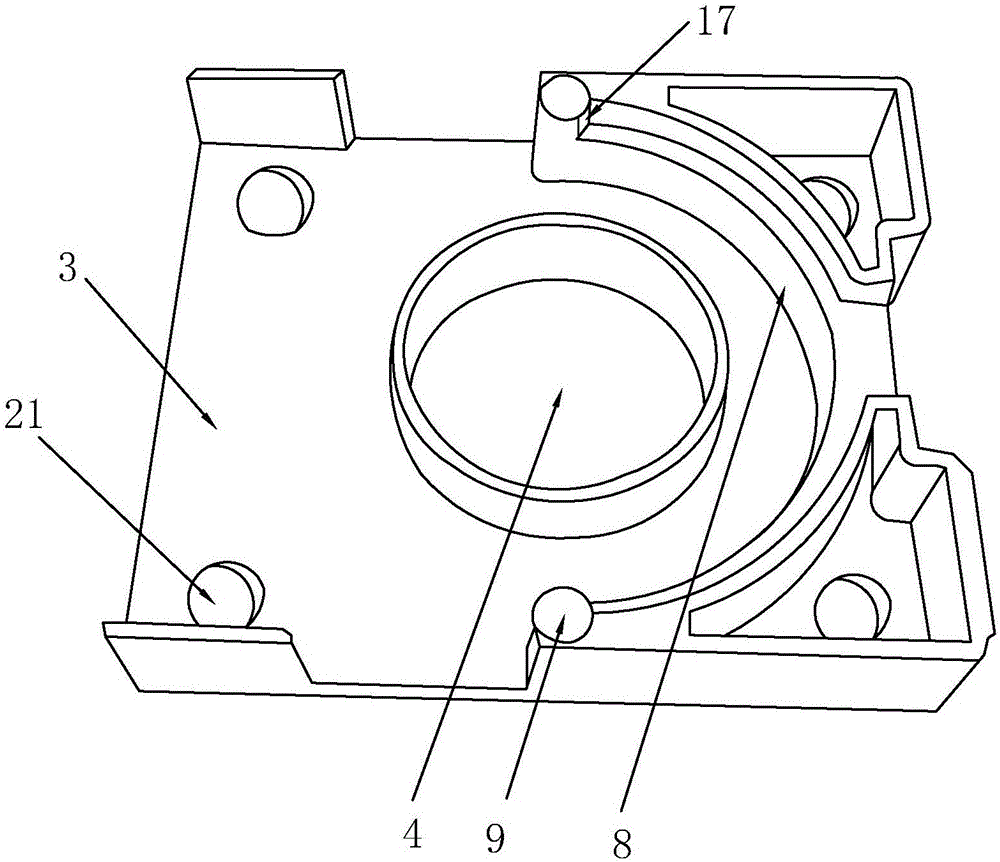

[0033] refer to Figure 1 to Figure 9 The embodiments of the inner core part of the lock and the handle door lock using the inner core part of the lock will be further described.

[0034] refer to Figure 1 to Figure 8 The inner core of a lock shown includes a return spring 1 with two positioning ends 2, a bottom plate 3, a penetration hole 4 provided on the bottom plate 3, and a handle formed by a fixed connection between a rotating shaft 5 and a bottom plate 6. 7. The handle 7 is installed on the penetration hole 4, the rotating shaft 5 and the bottom plate 6 are respectively located on both sides of the bottom plate 3, and the bottom plate 6 is set against the side of the bottom plate 3, and the bottom plate 3 extends outward An arc-shaped convex edge 8 is provided.

[0035] refer to figure 1 , 3 , 4 and 7, the return spring 1 passes through the rotating shaft 5 and contacts the bottom plate 3, and the two positioning ends 2 on it are respectively located outside the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com