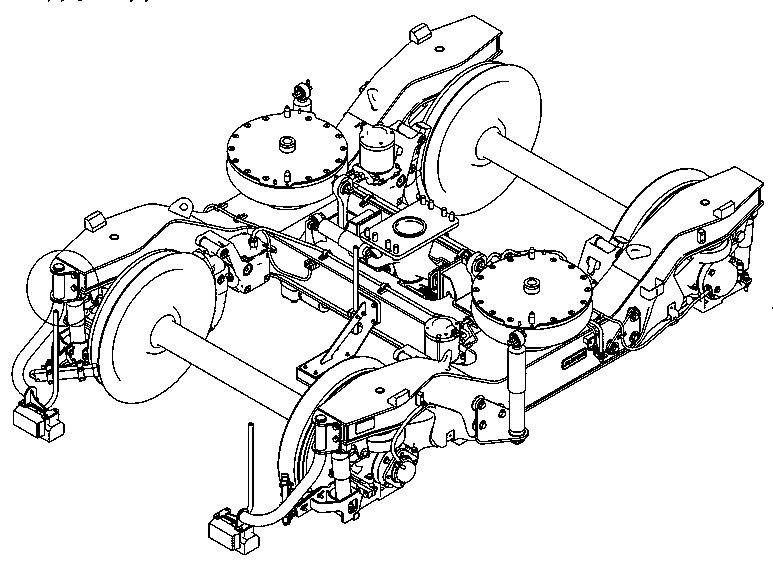

Positioning structure of antenna support and bogie

An antenna support and positioning structure technology, applied in bogies, antenna supports/installation devices, antennas suitable for movable objects, etc., can solve the problem of increased dynamic load of the antenna support, affecting driving safety, and single-head bolts 4 broken and other problems, to achieve the effect of improving the axial force state, increasing the length, and increasing the amount of elastic deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

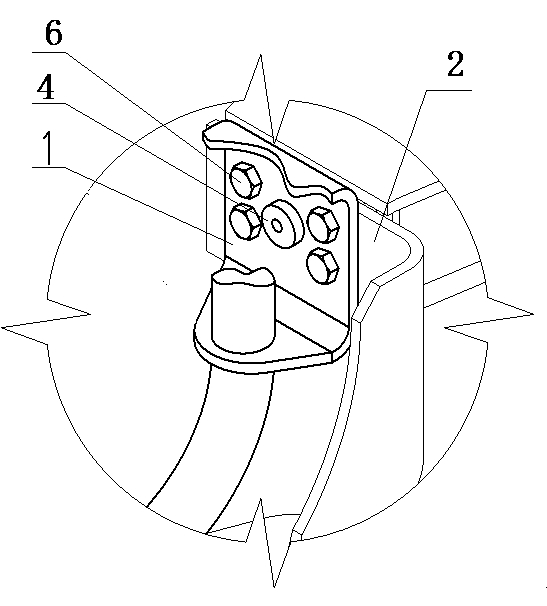

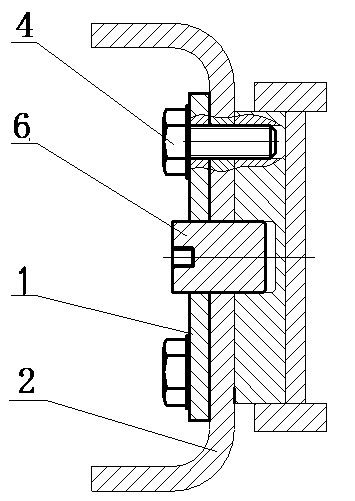

[0023] Such as Figure 5 with Image 6 As shown, the present invention proposes a positioning structure for the antenna support and the bogie, the bogie positioning plate 1 is arranged on the bogie, the antenna support is provided with the antenna support positioning plate 2; the bogie positioning plate 1 and the The antenna bracket positioning plate 2 is arranged in adhering manner to form a positioning installation pair. Four positioning through holes are arranged on the positioning installation pair. The positioning through holes are symmetrically arranged in pairs with respect to the same central point.

[0024] The positioning structure also includes two sets of bolt fasteners for fastening the positioning installation pair; each set of bolt fasteners includes two single-headed bolts 4 and a threaded hole base 5; the threaded hole base 5 is provided with There are two threaded holes 501 ; the two threaded holes 501 correspond to the two single-head bolts 4 one by one. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com