Telescopic compensation connector for vacuum traffic pipeline

A pipeline and transportation technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/pipes, pipe components, etc. It can solve the high cost of corrugated expansion joints, the inability to compensate for packing, and the inapplicability of displacement compensation for vacuum transportation pipelines, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

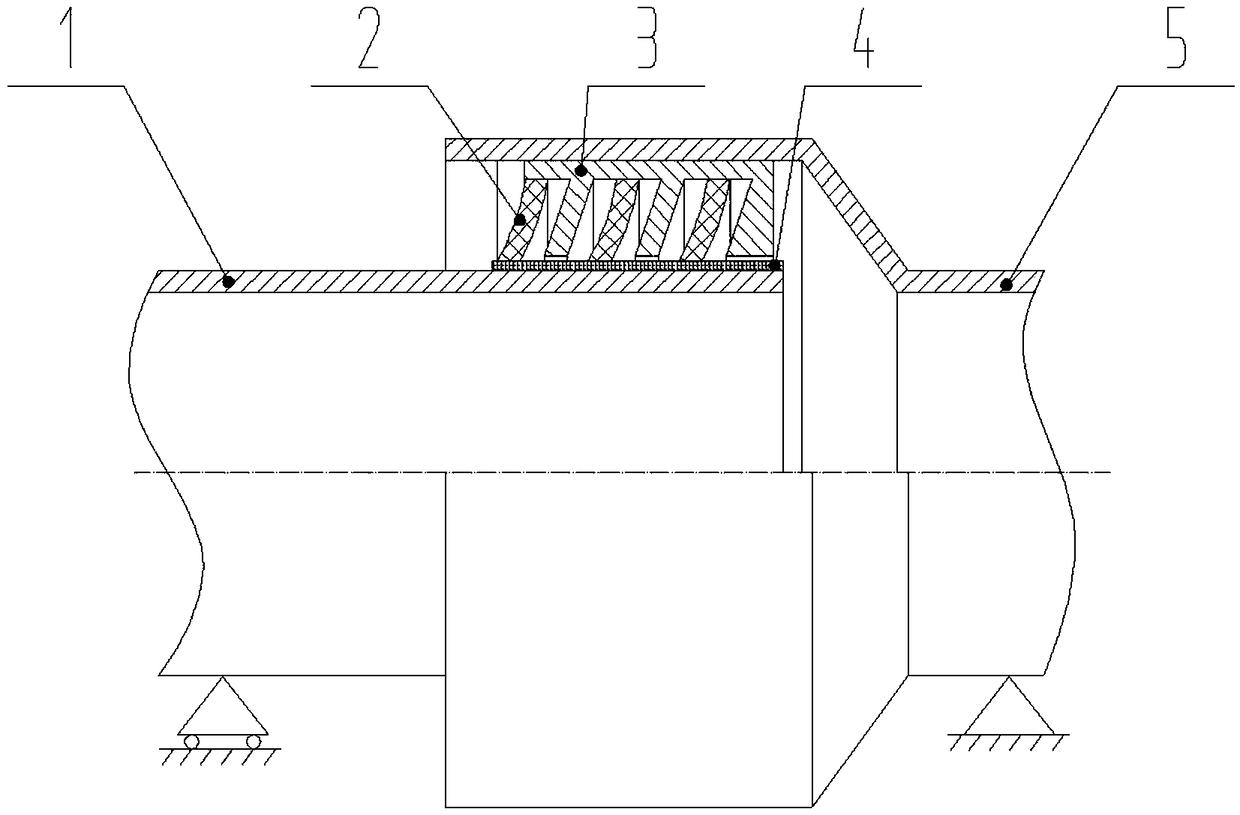

[0016] Embodiment 1: attached figure 1 represents this example

[0017] The straight end 1 of the pipe and the socket end 5 of the pipe are made of steel, and can also be ordinary carbon steel, stainless steel, weathering steel or other materials capable of sealing gas. One of the two butted pipe ends is fixed, and the other is movable in the axial direction. A sealing layer 4 on the outer surface of the pipe is laid along the outer diameter surface of the straight end 1 of the pipe. The sealing layer 4 on the outer surface of the pipe needs to have certain wear resistance, elasticity and self-lubricating properties. The sealing layer 4 on the outer surface of the tube can be made of materials such as expanded graphite or carbon fiber reinforced polytetrafluoroethylene. Among them, expanded graphite has excellent properties such as good compressibility, resilience, self-adhesiveness, low density, etc., and can be used for a long time under high temperature and highly corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com