Elastic piston and high pressure pumping system and method

A technology of elastic piston and piston cavity, which is applied to parts of pumping devices for elastic fluids, pump elements, variable displacement pump parts, etc., can solve problems such as pipeline rupture, pipeline impact, damage, etc., and achieve reduction Requirements for processing accuracy, reduced manufacturing costs, and the effect of large elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

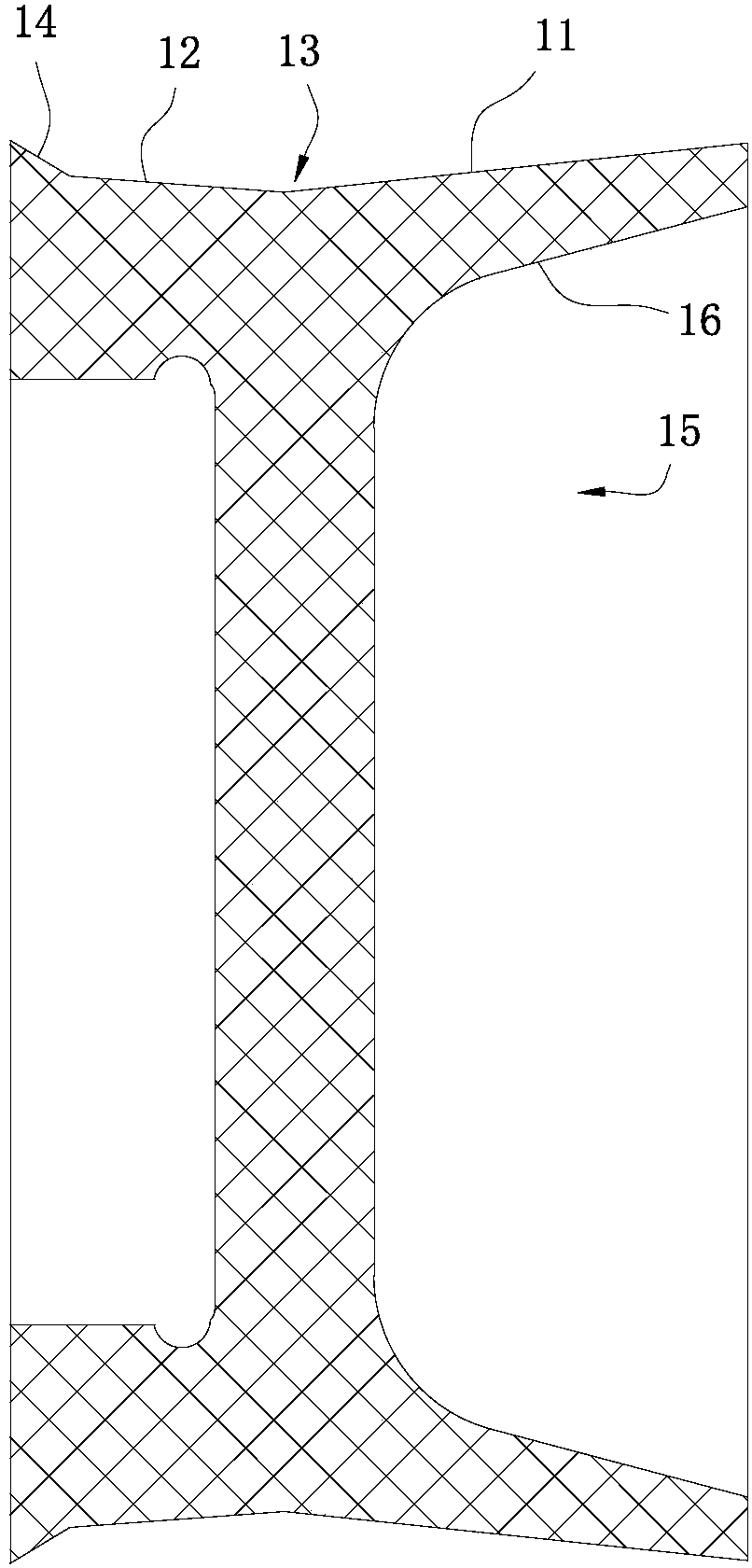

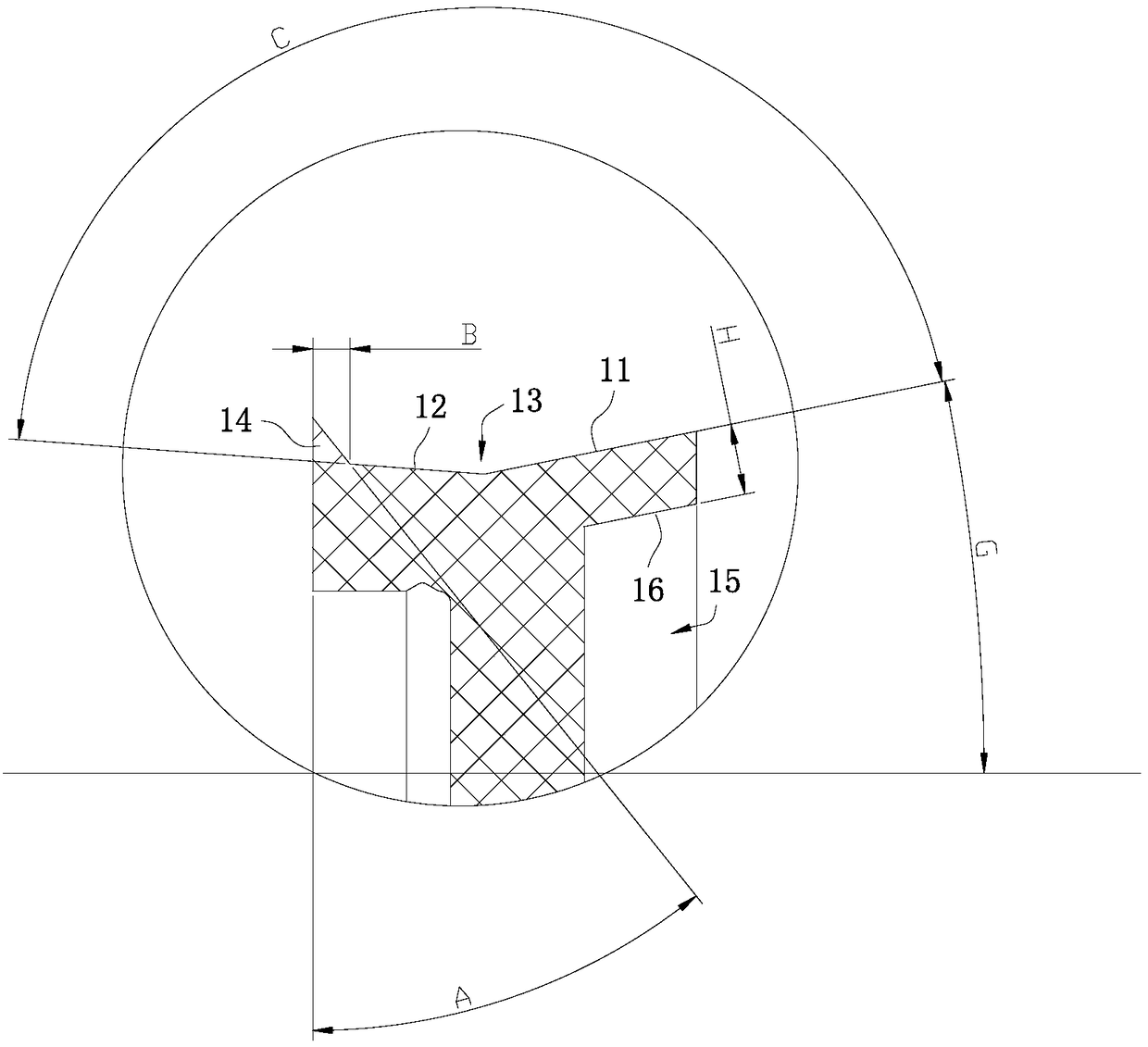

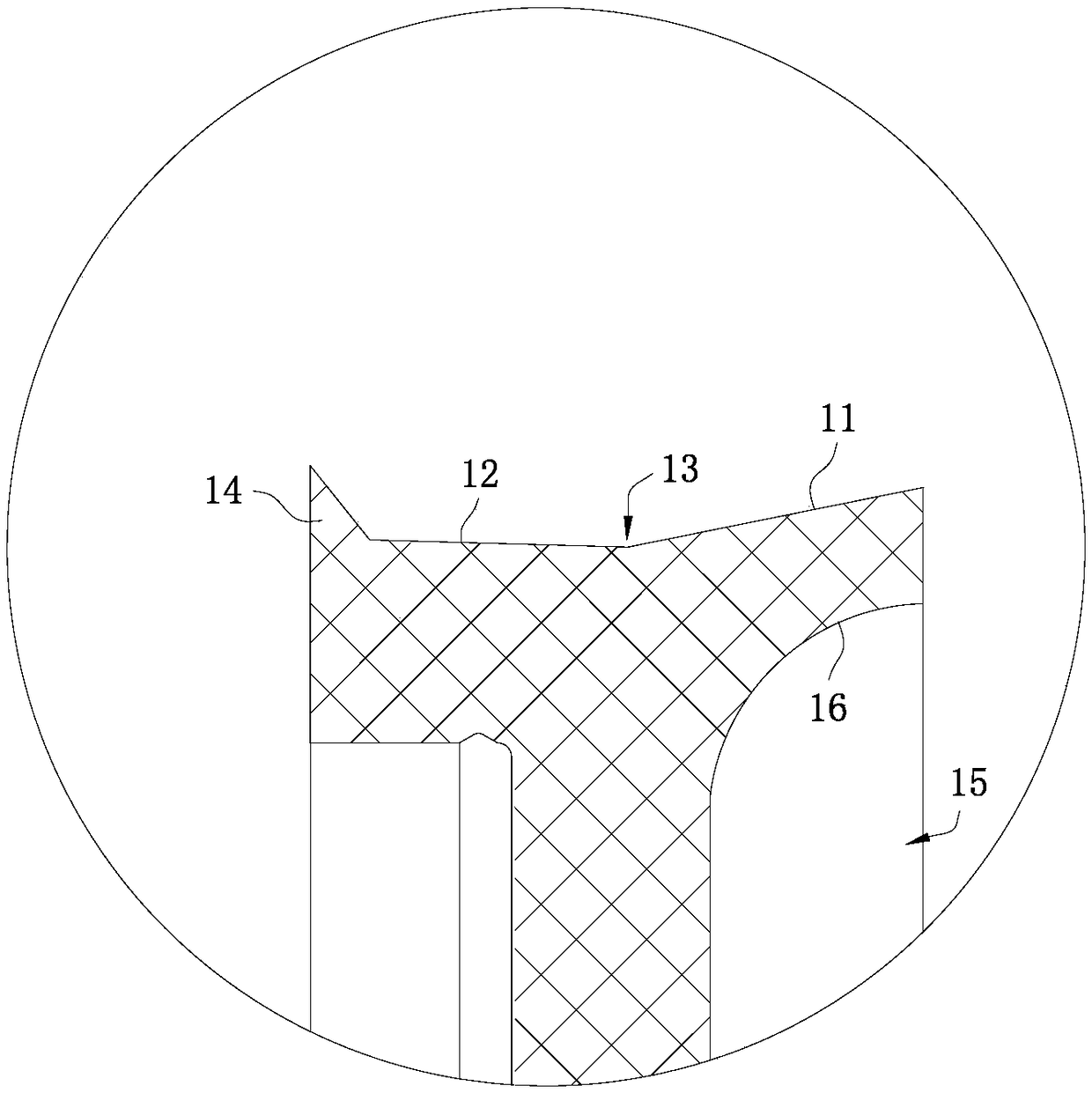

[0024] refer to Figure 1 to Figure 4 , the elastic piston of the present invention includes a piston body, and the front side and the rear side of the circumferential side wall of the piston body respectively form a front side inclined wall 11 and a rear side inclined wall 12. Preferably, the front side inclined wall 11 and the rear side inclined wall 12 are directly connected to each other. Intersect, of course, also can also be connected by connecting wall between front side inclined wall 11 and rear side inclined wall 12, due to the setting of front side inclined wall 11 and rear side inclined wall 12, there will be The recessed area 13 is formed. When the piston body is received in the wall of the piston cavity, the middle area of the piston body does not form contact with the wall of the piston cavity. There is a first included angle C between the front inclined wall 11 and the rear inclined wall 12 , preferably, the first included angle C is greater than 60° and less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com