Vibrating sand screening device for 3D printing

A 3D printing and vibrating device technology, applied in the fields of sieves, solid separation, chemical instruments and methods, etc., can solve problems such as screening blind areas, enhance the screening effect, reduce screening dead angles, and avoid inelastic deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

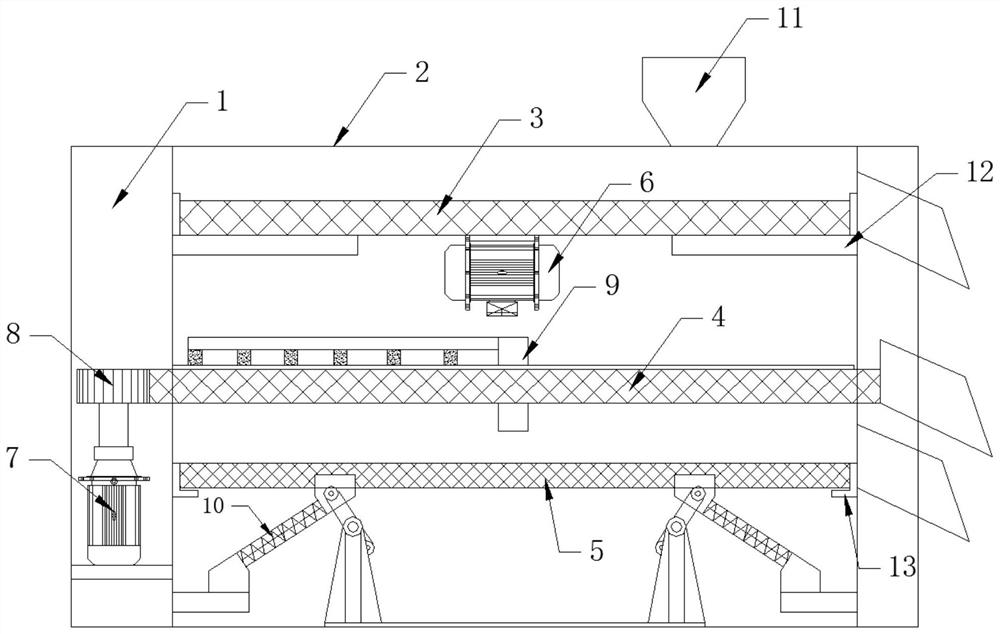

[0024] A vibrating sand screening device for 3D printing, comprising a frame 1, the periphery of the frame 1 is connected with an organic casing 2, and the frame 1 is sequentially installed with a primary sieve plate 3, a secondary sieve plate 4 and a third sieve plate from top to bottom. The first-stage sieve plate 5, the first-stage sieve plate 3 is connected with a vibrating motor 6, the side of the second-stage sieve plate 4 is provided with meshing teeth, and a rotating motor 7 is installed in the frame 1, and the rotating motor 7 is connected with a driving gear 8, and the driving gear 8 cooperates with the meshing teeth, and a rolling device 9 is installed on the secondary sieve plate 4, and a reciprocating vibration device is connected to the bottom of the third-stage sieve plate 5. The direction is inclined to the horizontal plane, and the vibrating spring 10 is connected with a driving device. The size of the sieve holes on the third-stage sieve plate 5 is smaller tha...

Embodiment 2

[0027] On the basis of Embodiment 1, the rolling device 9 includes a fixed shaft, the fixed shaft is fixedly connected to the frame 1, a bearing is connected between the secondary sieve plate 4 and the fixed shaft, and a roller connecting frame is connected to the upper end of the fixed shaft. A plurality of rollers are installed on the wheel connecting frame.

[0028] The relative motion structure of the rotating sieve plate and the stationary grinding wheel uses the principle of centrifugal force to overcome the problem that the grinding wheel can only act on the sand on the path of the grinding wheel when the grinding wheel rotates. The bottom moves gradually from the center of the sieve plate to the periphery of the sieve plate, and evenly contacts with the roller.

Embodiment 3

[0030] On the basis of Embodiment 1, the bottom of the primary sieve plate 3 is connected with a support plate 12, the support plate 12 is connected with the frame 1, and the sides of the primary sieve plate 3 and the third stage sieve plate 5 are connected with the frame 1 Flexible support block 13 is arranged. Through the cooperation of the support plate 12 and the flexible support block 13, the sand material can be prevented from leaking downward from the side while meeting the vibration space requirement of the sieve plate, and the unscreened sand material can be prevented from falling into the next-level screening mechanism to realize sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com