Quick wiring structure

A wiring structure and fast technology, applied in the direction of connection, conductive connection, contact parts, etc., can solve the problems of wiring, slow wire taking, inconvenient wiring, taking wire, slow axial movement of screws, etc., to improve the fixing strength , fast and convenient wiring, and the effect of improving the electrical connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

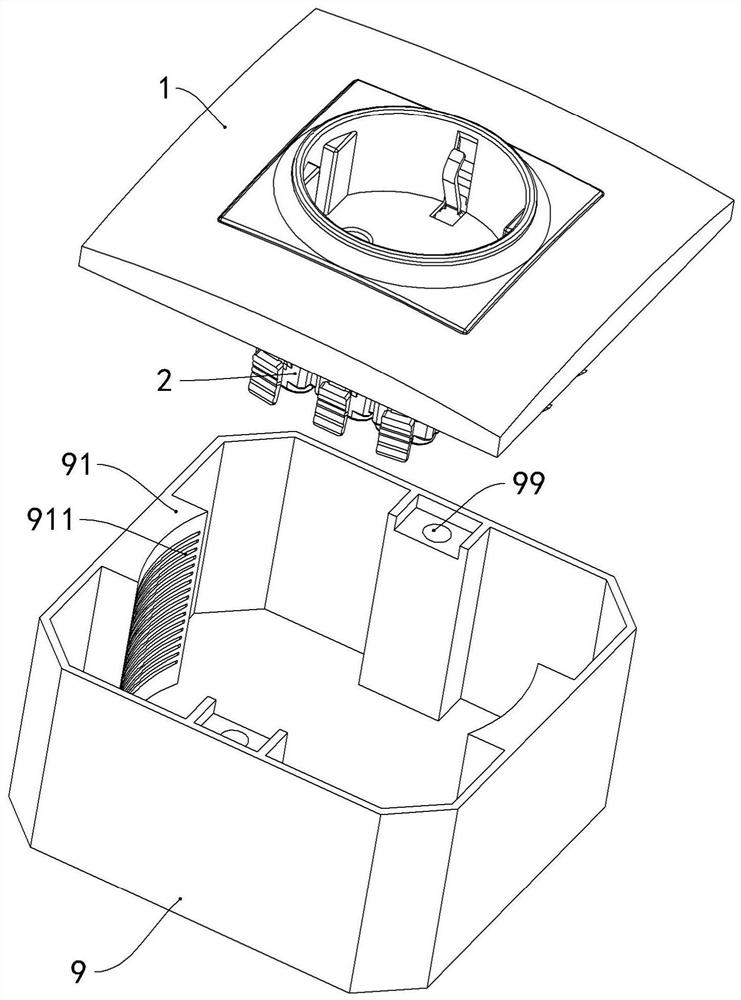

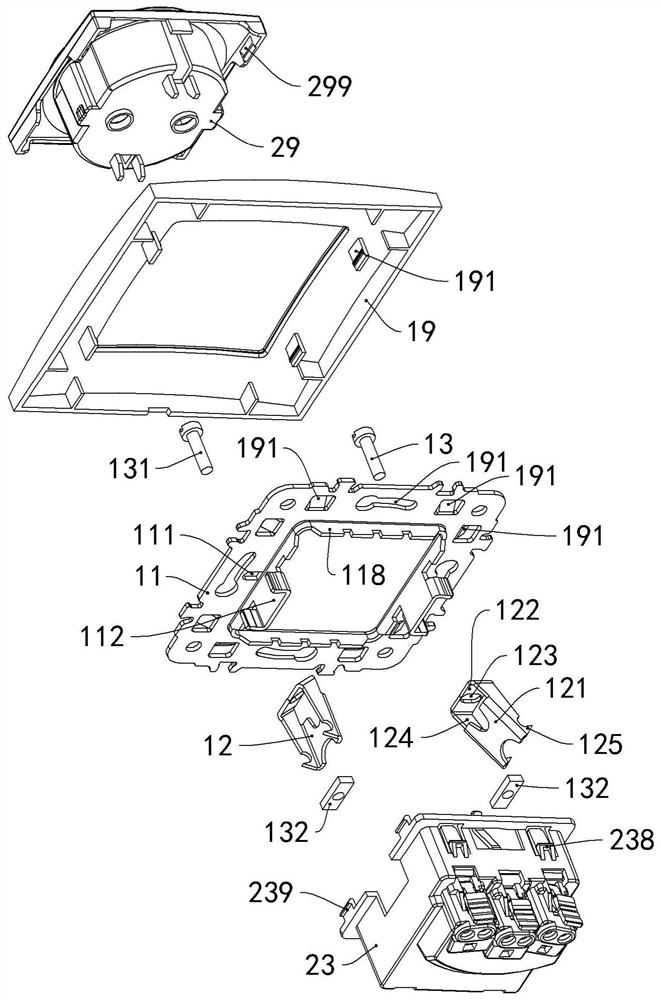

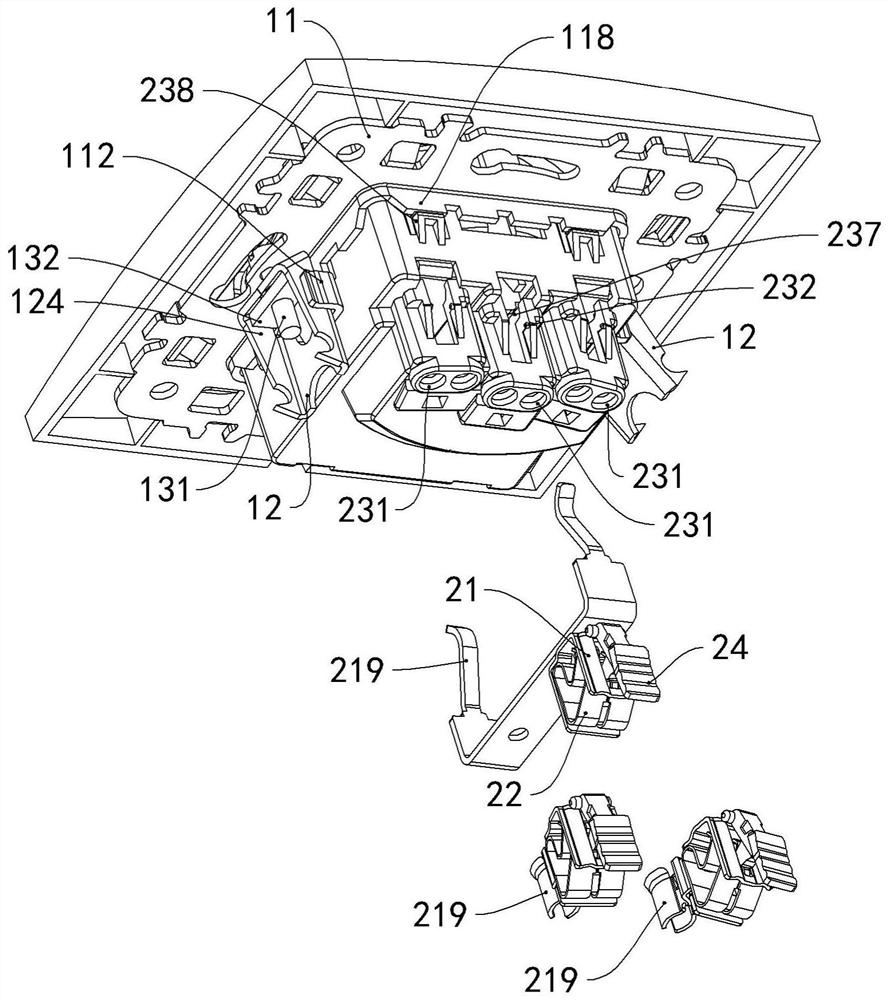

[0042] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings of the present invention.

[0043] The mounting board structure of the present invention includes a mounting assembly 1 , and the mounting assembly 1 includes a mounting board 11 , a mounting resist 12 and at least two locking assemblies 13 . Usually, each locking assembly 13 is rotationally symmetrical around the center line of the mounting plate 11, so as to ensure that when the tilting piece 121 is against the bottom box 9, the mounting plate 11 is evenly stressed and will not deviate from the bottom box 9 [that is, the center of the two line misalignment].

[0044] The installation resisting member 12 includes a lifting piece 121 and a locking plate 122 fixedly connected with the lifting piece 121 .

[0045] A tilting angle β is set between the tilting piece 121 and the locking plate 122, and the tilting angle β is less than ninety degrees and grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com