Article screening device based on industrial Internet of Things

An industrial internet of things and screening device technology, applied in the field of screening, can solve the problems of gap adjustment that cannot be screened, small screening range, etc., and achieve the effect of increasing the screening range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

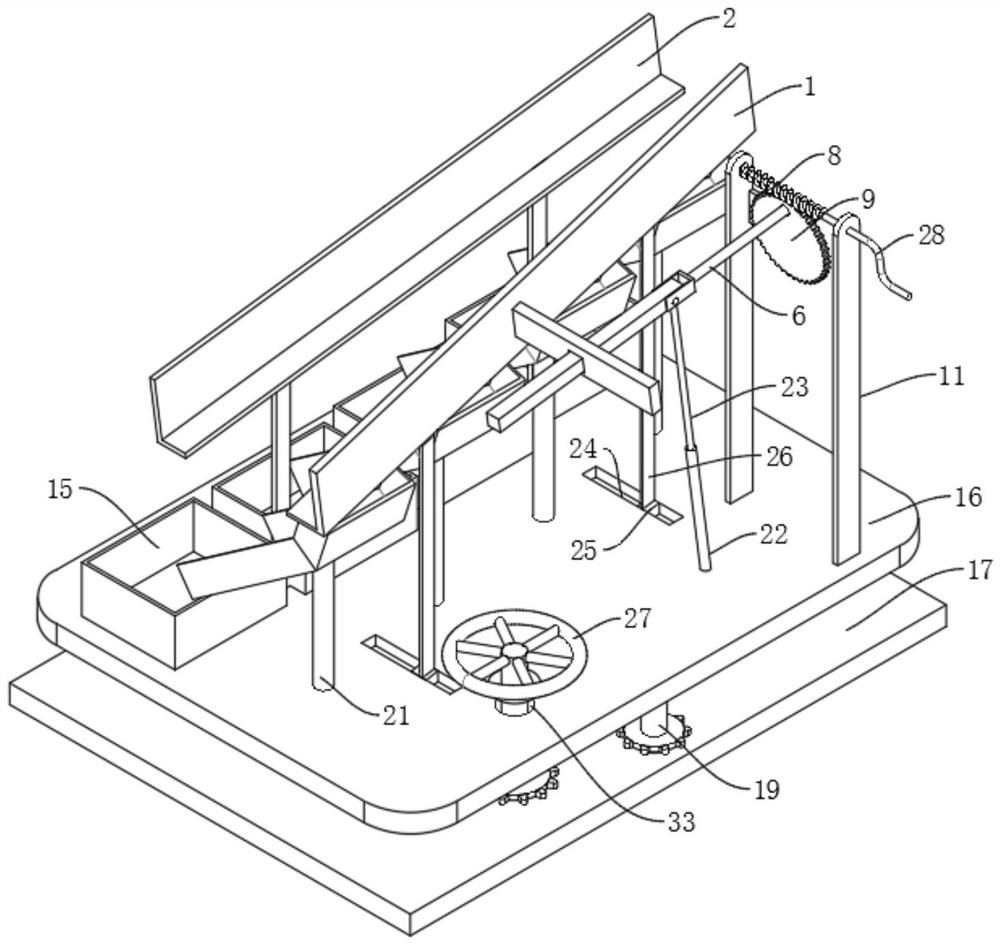

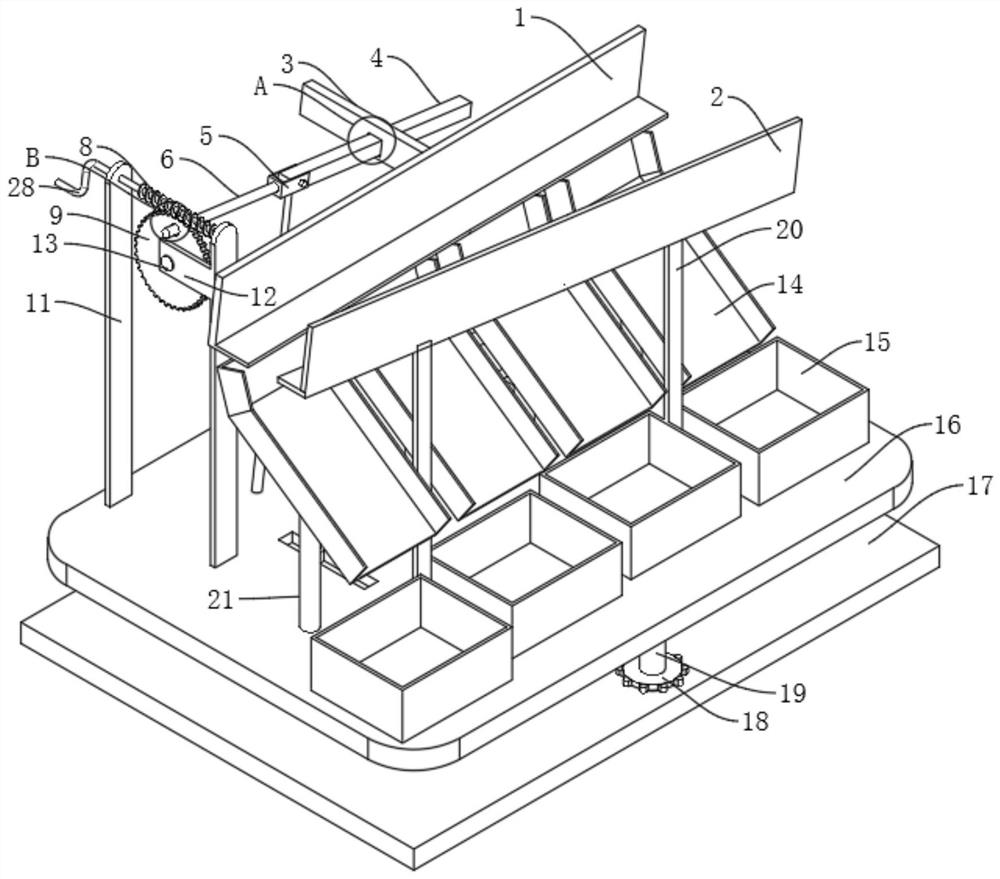

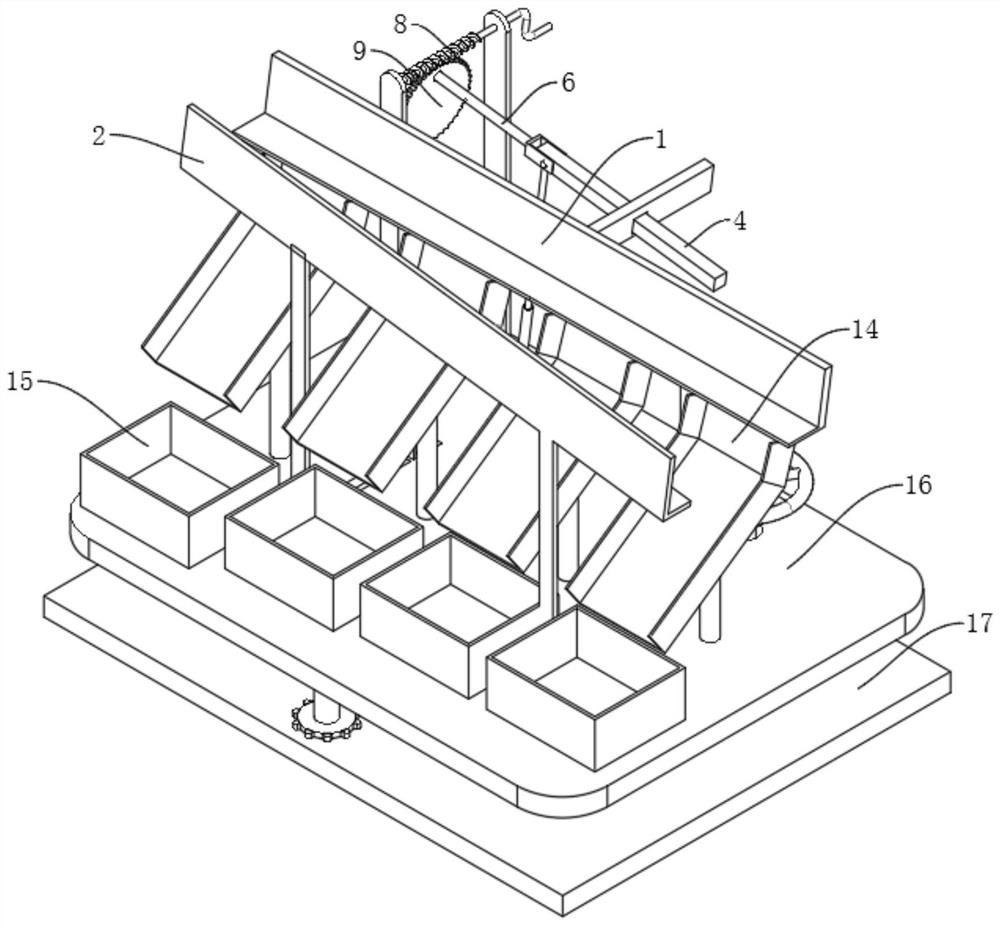

[0023] refer to Figure 1-6 , Figure 8 , Figure 9 , an item screening device based on the Industrial Internet of Things, comprising a middle plate 16, both ends of the upper surface of the middle plate 16 are fixedly connected with support legs 20, and the support legs 20 are fixedly connected with a second support plate 2, the second The support plate 2 is arranged obliquely, and the two ends on the other side of the upper surface of the middle plate 16 are connected with connecting legs 26 through a sliding mechanism. To form a screening channel, by connecting the transmission belt at the upper end of the second support plate 2, the upper surface of the transmission belt is flush with the upper bottom surface of the first support plate 1 and the second support plate 2, and the items pass through the transmission belt and enter the screening channel. The gap of the channel increases gradually from top to bottom, so that items of different sizes will slide down. Smaller it...

Embodiment 2

[0029] In Example 1, since the heights of the first support plate 1 and the second support plate 2 cannot be adjusted, when the transmission belt is used to transport items, only a fixed-height transmission belt can be used to transport the items to the screening device , refer to Figure 1-5 , Figure 7 , as another preferred embodiment of the present invention, on the basis of Embodiment 1, the lower end of the middle plate 16 is provided with a bottom plate 17, and the middle position of the bottom plate 17 is rotatably connected with a driven shaft 32 through a thrust ball bearing. On the driven shaft 32 The driven gear 31 is fixedly connected, and the four sides of the bottom plate 17 are rotatably connected with threaded sleeves 19 through thrust ball bearings. The four threaded sleeves 19 are fixedly connected with transmission gears 18, and the four transmission gears 18 mesh with the driven gear 31. , the lower surface of the middle plate 16 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com