Camera stroboflash prevention device

An anti-camera and stroboscopic technology, applied in camera, exposure control, optics, etc., can solve the problems of unavoidable stroboscopic, camera stroboscopic, changing light source environment, etc., to avoid camera stroboscopic, reduce size, work station compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

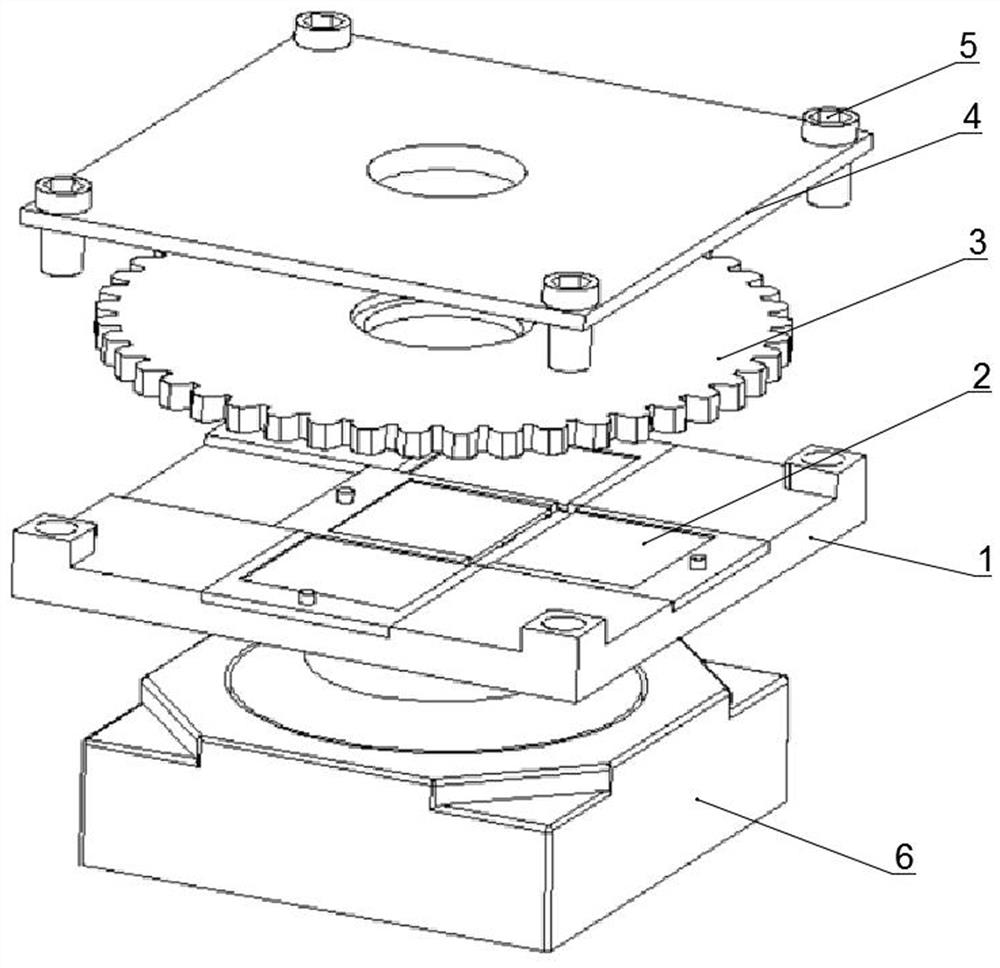

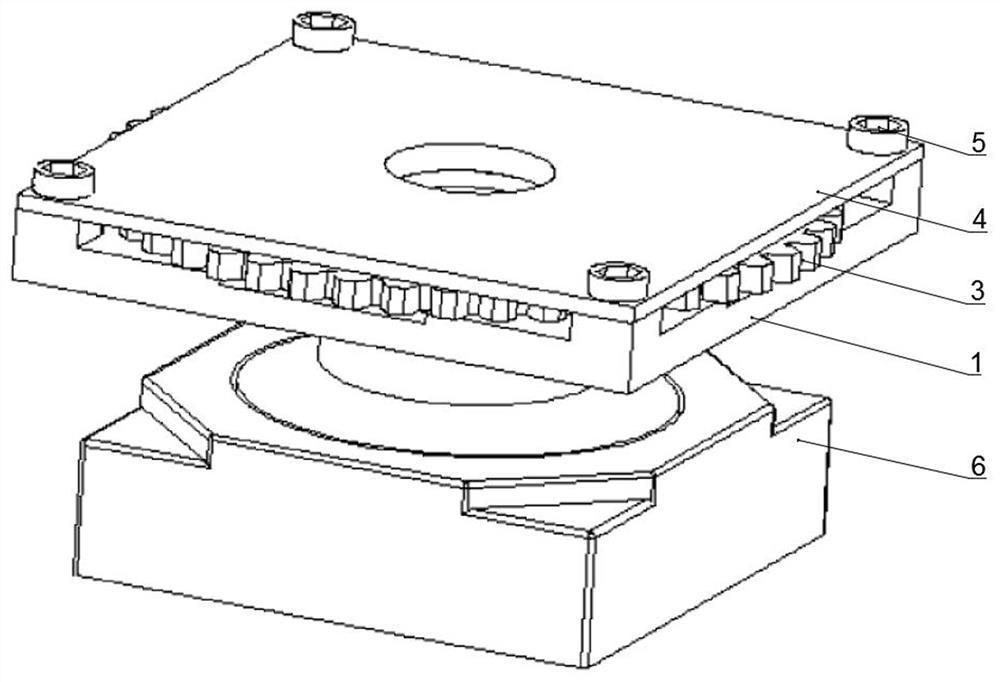

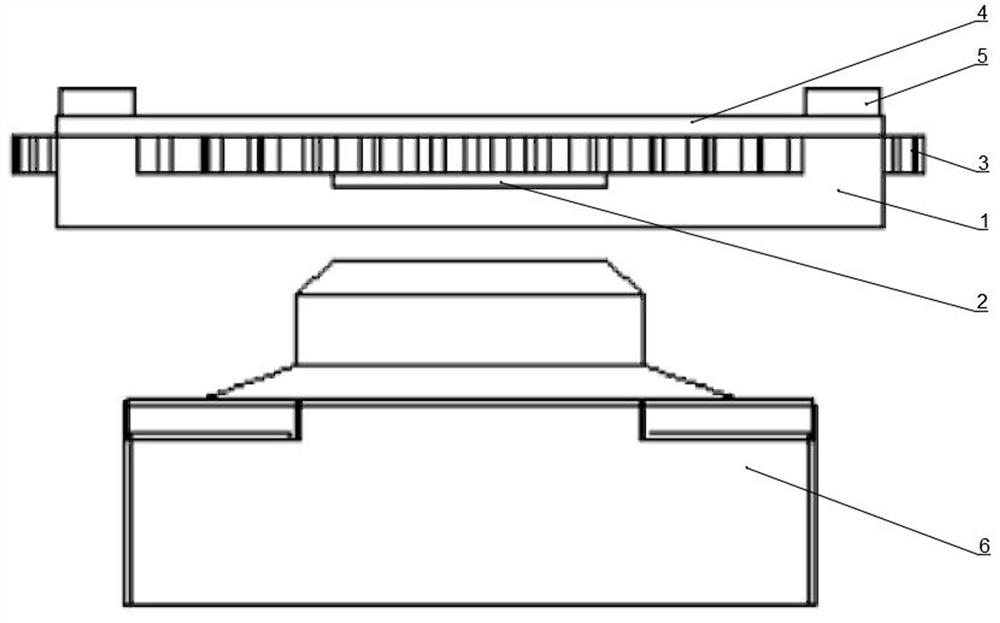

[0039] An anti-camera strobe device such as Figure 1-Figure 7As shown, including light reduction film module and motion mechanism. The anti-camera stroboscopic device is fixed in front of or directly above the lens of the camera module 6, the camera module 6 and the light reduction film module are connected to the MCU, and the movement mechanism is controlled by the MCU, which can push the light reduction film assembly 2 to slide. The light-reducing film module includes a guide rail plate 1 and a light-reducing film assembly 2, and the light-reducing film assembly 2 is slidably matched with the guide rail plate. The light reduction film module is located below the moving mechanism, close to the camera module 6, and there is a certain gap between the bottom of the light reduction film module (that is, the bottom of the guide rail plate) and the lens of the camera module 6. When reaching the farthest point, the outer edge of the lens is not in contact with the light reduction ...

Embodiment 2

[0056] An anti-camera stroboscopic device, the difference from Embodiment 1 is that the guide groove is in the shape of a line, and there are 3 moving stations, including 2 fixed stations and a central station at both ends; the guide groove There are two groups of light-reducing film assemblies 2 inside, and the length of the guide groove is three times the length of the light-reducing film assembly; the curve C of the drive groove 7 of the wheel disc 3 consists of a large arc of more than 3 / 4 and a free curve that is concave Composition, the difference between the furthest distance and the shortest distance from the center point of the curve C is just equal to the travel range of each light-reducing film assembly 2 . All the other parts are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com