Anti-storm elbow for deepwater net cage

A deep-water cage, wind and wave resistance technology, applied in application, climate change adaptation, fish farming, etc., can solve problems such as stress concentration and breakage at corners, and achieve the effect of improving strength and improving wind and wave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

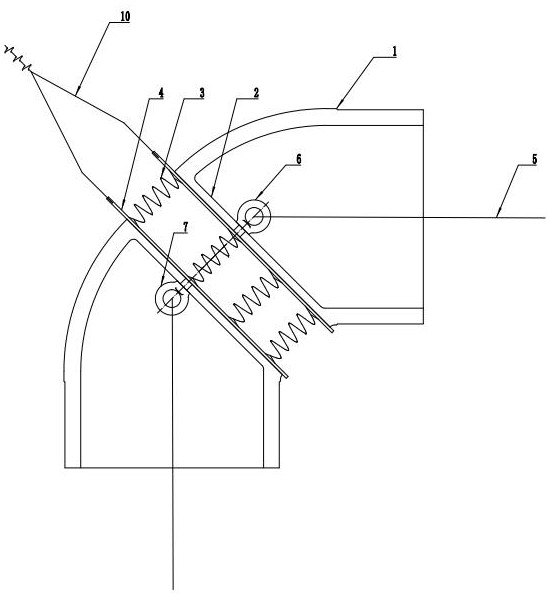

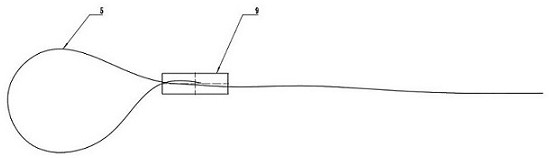

[0022] A flexible anti-wind and wave elbow for deep water cages. The elbow is divided into two parts for production. The first part 11 of the elbow is exactly the same as the second part, including: main body 1, partition plate 2, steel sheet 4, and steel wire rope 5 , ring screw 6 and ring nut 7, supporting screw nut 8, aluminum sleeve 9, characterized in that the material of the main body and the partition is high-density polyethylene material, which is integrally formed in the injection molding machine by the injection molding process. The two parts are connected by a spring to form a flexible whole.

[0023] The main body 1 is half of a high-density polyethylene 90-degree elbow.

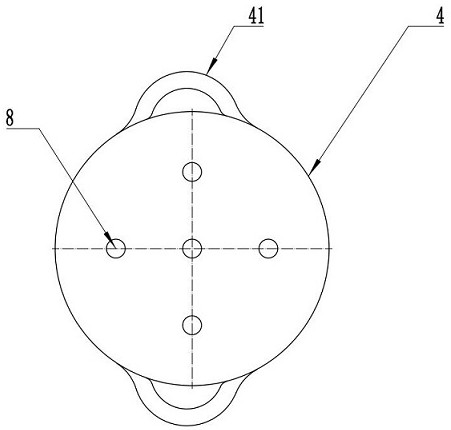

[0024] There are 5 holes on the dividing plate 2, one in the middle, and the other 4 holes are distributed around the center.

[0025] The steel sheet 4 is located on the outside of the partition 2, and the partition 2 and the steel sheet 4 are tightly connected by four matching screws and nuts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com