Improved floating type wind-wave-resisting net cage

A kind of wind and wave resistance, improved technology, applied in fish farming, application, climate change adaptation and other directions, can solve the problems of insufficient firmness, poor wind and wave resistance, low cost, etc., to increase safety, reduce impact force, increase The effect of wind and wave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

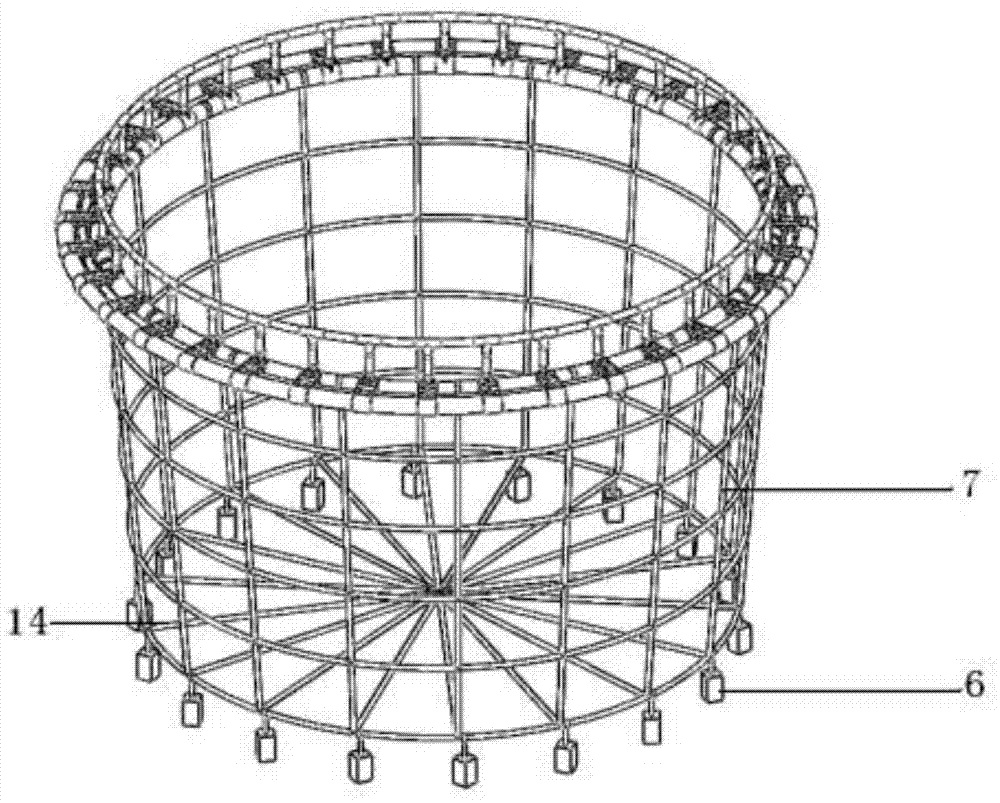

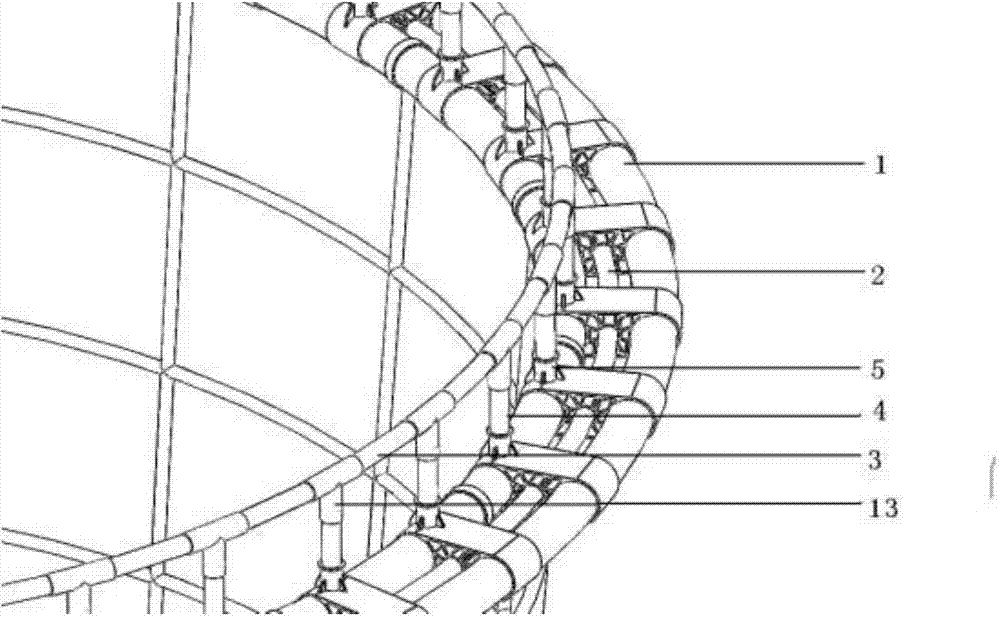

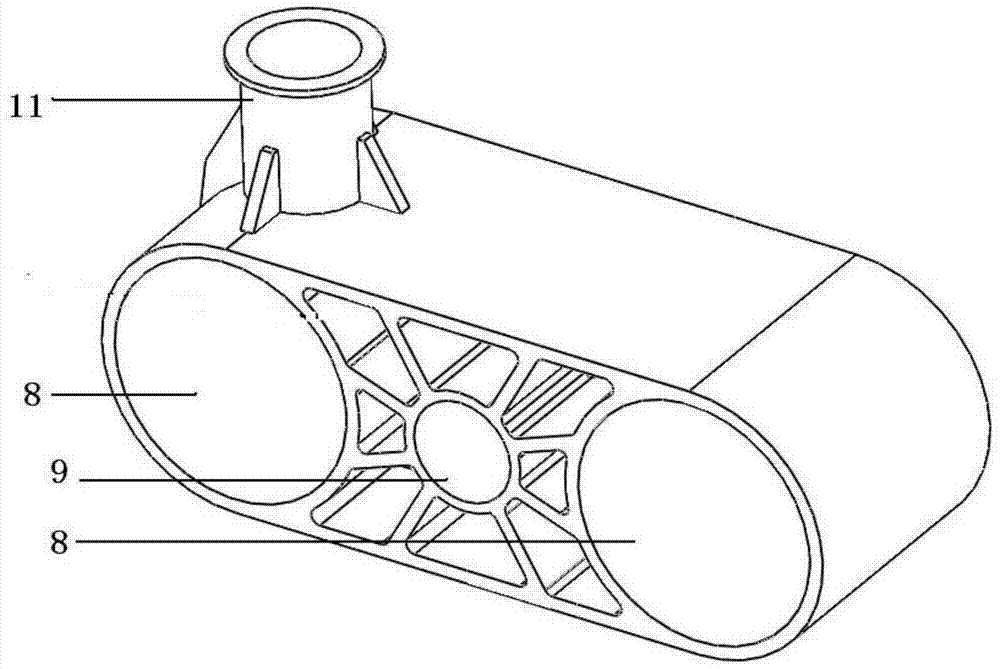

[0018] An improved floating anti-storm net cage, such as figure 1 Shown, comprise net cage skeleton main body and be placed in the net clothing in the net cage skeleton main body, net cage skeleton main body comprises 2 horizontal main buoyancy tubes 1, 1 horizontal secondary buoyancy tube 2, horizontal guardrail 3, vertical Guardrail 4, connecting pipe fittings 5, anchor stones 6 and grid-shaped submerged water skeleton 7; the connecting pipe fittings have two horizontally transparent main holes 8, and one horizontally transparent auxiliary hole 9, and the auxiliary holes are located in the two main holes. In the middle of the hole, there are 6 transparent small holes 10 on the periphery of the auxiliary hole. The connecting pipe has a vertical joint 11 in the vertical direction. Two horizontal main buoyancy pipes pass through the two main holes of the connecting pipe. One horizontal secondary buoyancy pipe passes through the auxiliary hole in the middle of the connecting pip...

Embodiment 2

[0028] An improved floating anti-wind and wave net cage, comprising a main frame of the net cage and a netting placed inside the main body of the net cage, the main body of the net cage includes two horizontal main buoyancy tubes, one horizontal secondary buoyancy tube, horizontal Guardrails, vertical guardrails, connecting pipe fittings, anchor stones and grid-like submerged water skeletons; the connecting pipe fittings have two horizontally transparent main holes and one horizontally transparent auxiliary hole, and the auxiliary hole is located between the two main holes. In the middle, there are 5 transparent small holes around the auxiliary hole, the connecting pipe has a vertical joint in the vertical direction, 2 horizontal main buoyancy pipes pass through the 2 main holes of the connecting pipe, and 1 horizontal The secondary buoyancy pipe passes through the auxiliary hole in the middle of the connecting pipe, the vertical guardrail is inserted into the vertical joint of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com