An all-electric bending machine system with grating ruler to compensate bending depth

A grating ruler and bending machine technology, applied in the field of all-electric bending machines, can solve the problems of reduced efficiency, overshoot, and failure to reach the position at one time, and achieve the effects of improving processing efficiency, high precision, and saving compensation time

Active Publication Date: 2022-07-08

深圳市合信自动化技术有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the great pressure required when folding the plate, the frame is deformed or the belt is stretched and deformed, causing the position of the Y-axis servo encoder to reach the given bending position, but the actual slider position does not reach it. Due to the amount of deformation, there are many influencing factors. , it is difficult to calculate theoretically, that is, it is difficult to predict, so it cannot be done at one time

[0003] There are two existing schemes, the two-stage bending method and the compensation bending method. When the two-stage bending method is close to the target and switches to another stage, the speed drops very low (if it does not drop very low, it will decelerate and stop when it is in place, and it will overshoot. ), the efficiency decreases

If the grating ruler breaks during bending, the slider will keep pressing down, causing a safety risk. The compensation bending method first judges that the servo positioning is completed, and then compares the position to compensate. There will be a sense of pause, and the time will be longer. Efficiency Therefore, we propose an all-electric bending machine system that compensates the bending depth with a grating ruler

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

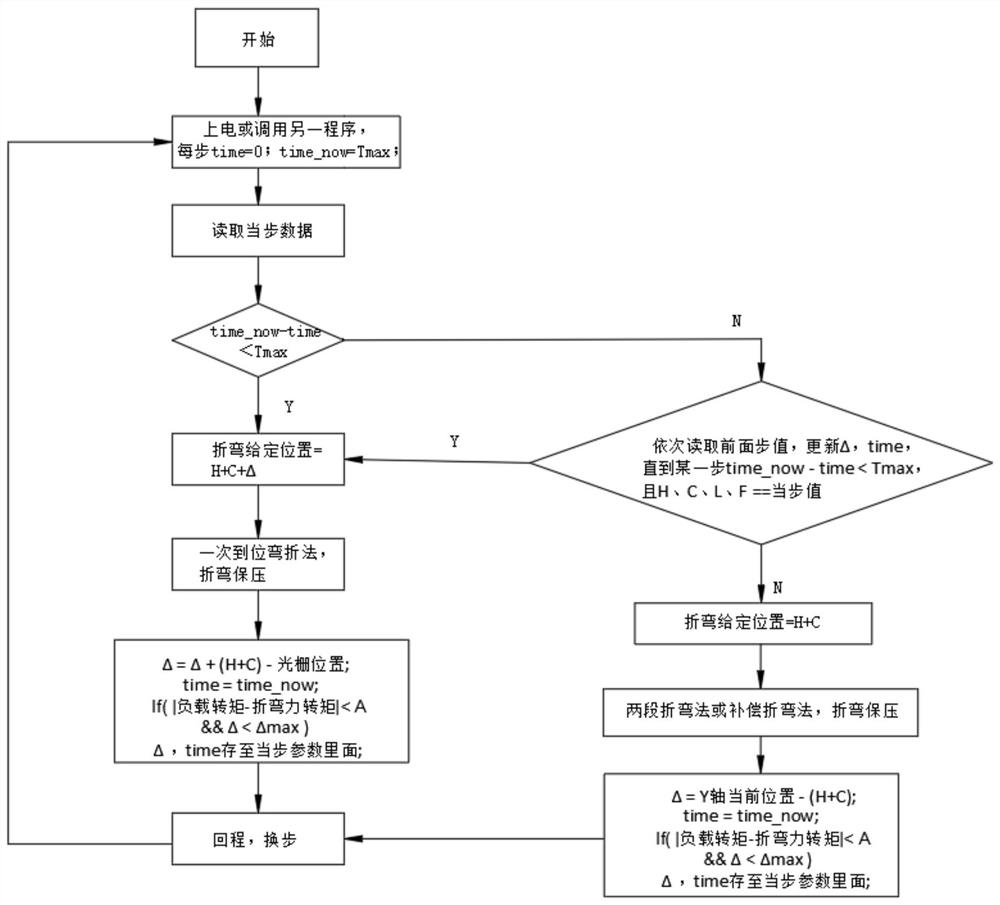

[0019] like figure 1 As shown, start the servo, edit the step, power on or call another program, time=0 for each step; time_now=Tmax; Tmax can be set to 5min or other empirical time, start, read the parameters of the current step, and judge the time_now-time and Tmax The size of the value between the two, if time_now-time

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an all-electric bending machine system in the technical field of all-electric bending machines with a grating ruler compensating the bending depth, including S1: servo increases two parameters per step, Δ and time; Depth H, correction depth C, bending width L, bending force F, changeable), time=0, power on or call another program, each step time=0; time_now=Tmax; Tmax can be set to 5min or other experience Time, S3: start, read the parameters of the current step, the grating scale compensates the bending depth of the all-electric bending machine system, by increasing the Δ compensation value, when the bending machine performs continuous bending, the compensation value is continuously updated to Eliminate the accumulated error during bending, ensure that the bending accuracy is high under continuous operation, and the bending is in place at one time, saving compensation time and improving processing efficiency.

Description

technical field [0001] The invention relates to the technical field of all-electric bending machines, in particular to an all-electric bending machine system for compensating bending depth with a grating ruler. Background technique [0002] The all-electric (servo) bending machine is two high-power servo motors installed on both sides of the machine. The pulley drives the screw to rotate, so that the slider moves up and down synchronously, so as to bend the workpiece and process the product. Due to the large pressure required for folding the plate, the frame is deformed or the belt is stretched and deformed, resulting in the position of the Y-axis servo encoder reaching the given bending position, but the actual slider position has not been reached. Due to the amount of deformation, there are many influencing factors , it is difficult to calculate theoretically, that is, it is difficult to predict, so it cannot be in place at one time [0003] There are two existing solutio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21D5/00

CPCB21D5/004B21D5/006

Inventor 王精

Owner 深圳市合信自动化技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com