Plate trimming machine

A technology of trimming machine and plate, applied in the direction of metal sawing equipment, sawing device, metal processing equipment, etc., can solve the problems of low processing accuracy, poor sawing stability, and affecting processing accuracy, and achieve high processing accuracy, Elimination of accumulated errors and good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

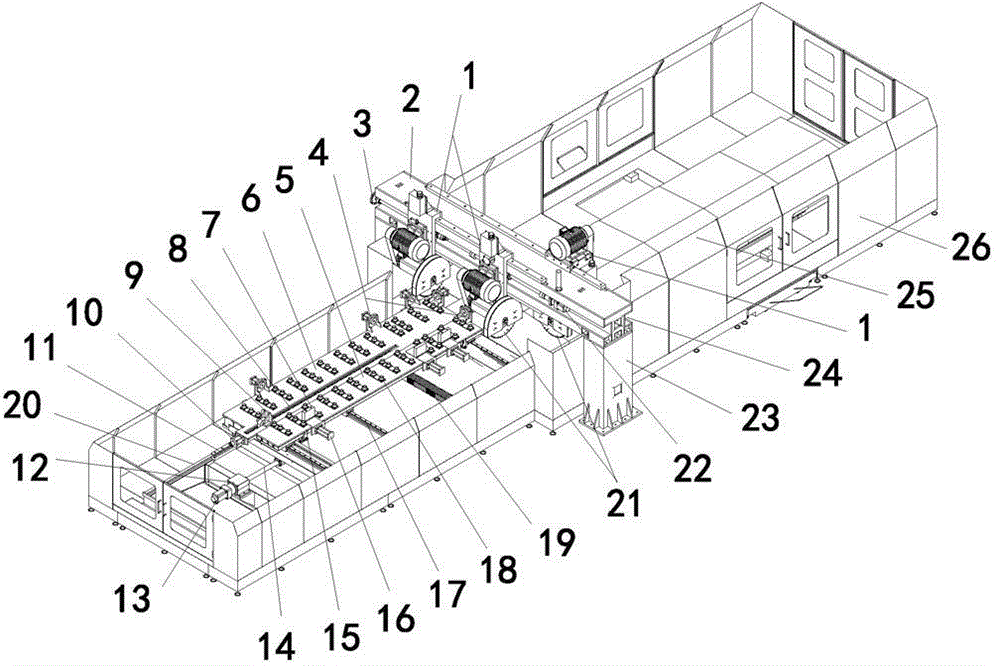

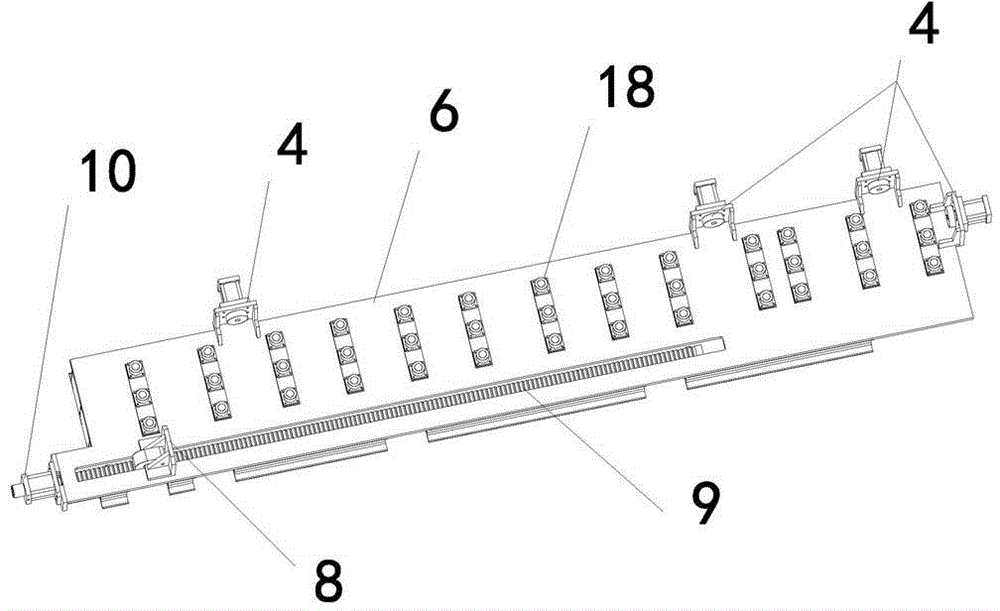

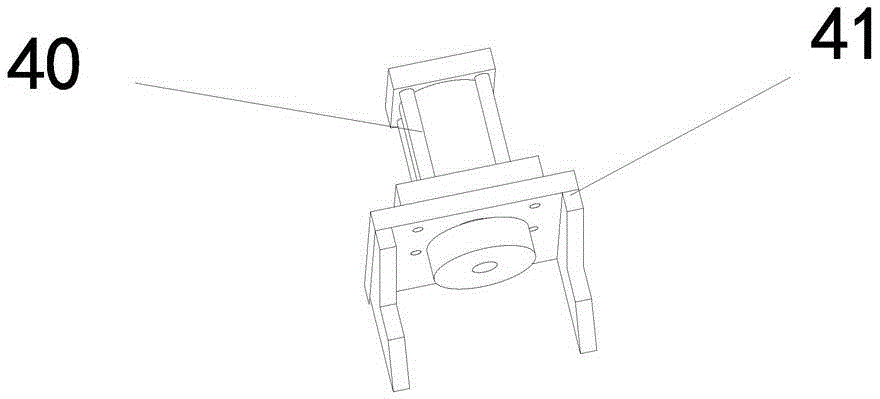

[0019] Description of drawings: 1-Circular saw device, 2-Saw beam, 3-Adjusting hand wheel, 4-Work clamp, 5-rear workbench, 6-front workbench, 7-movable splint, 8- Rack, 9-moving clamp body, 10-clamping cylinder, 11-lower guide rail, 12-motor seat, 13-servo motor, 14-screw rod, 15-adjusting drive device, 16-clamping cylinder, 17-up Guide rail, 18-longan device, 19-sheath, 20-base, 21-circular saw blade, 22-servo motor, 23-post, 24-saw beam groove, 25-inside bevel, 26-protective cover, 40-clamping cylinder, 41-fixed clamp seat, 180-ball, 181-ball seat.

[0020] Such as figure 1 As shown, a board trimming machine includes a base 20, a worktable, a saw beam 2 and a circular saw device 1. The saw beam 2 is provided with a movable circular saw device 1 on the right side, and the saw beam 2 on the left side Two movable circular saw devices 1 are provided; the saw beam 2 is connected with the top ends of the two uprights 23 to form a gantry, the base 20 below the saw beam 2 extends in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com