Concrete prefabricated component capable of being quickly connected

A prefabricated component and quick connection technology, applied in building components, structural elements, building reinforcements, etc., can solve the problems of troublesome installation and high installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

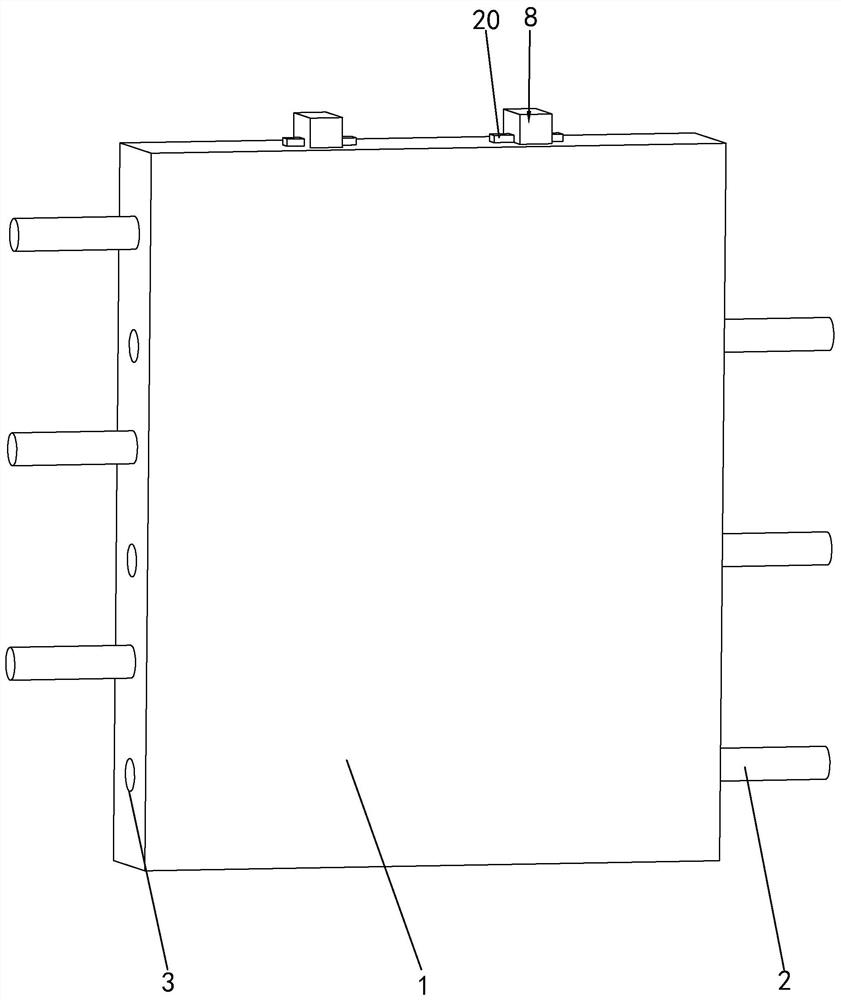

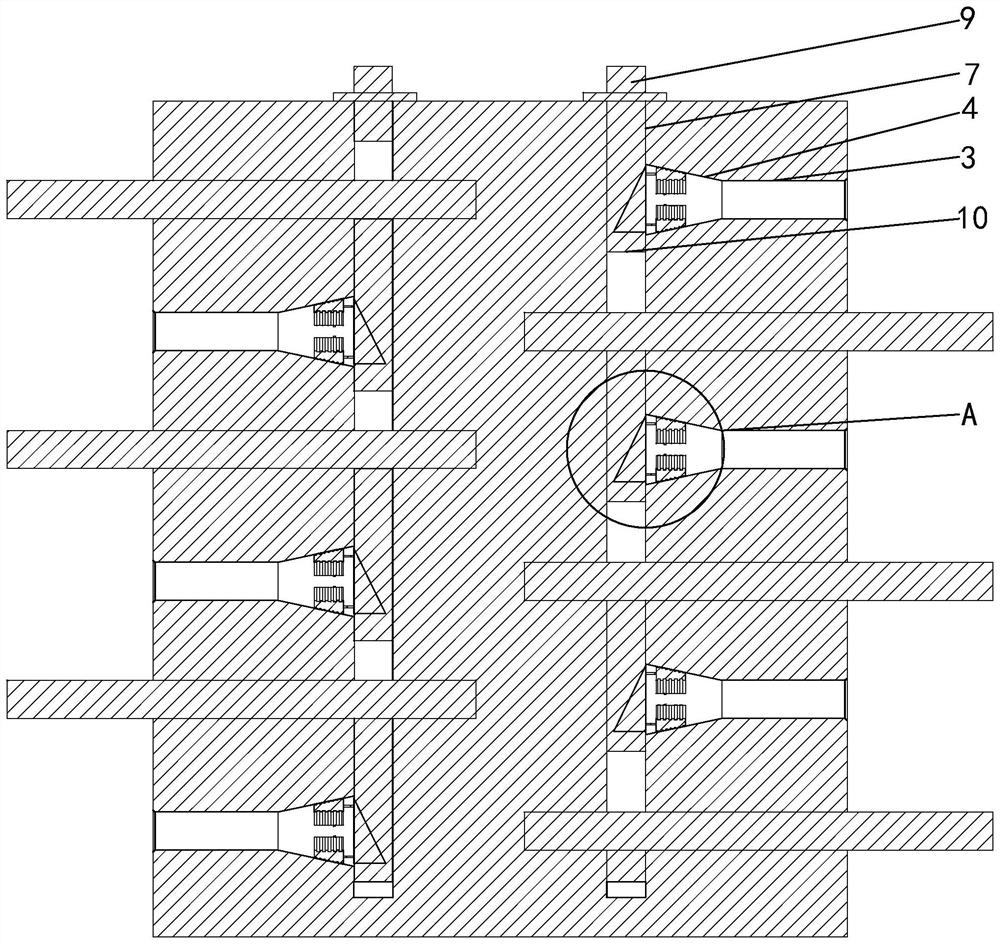

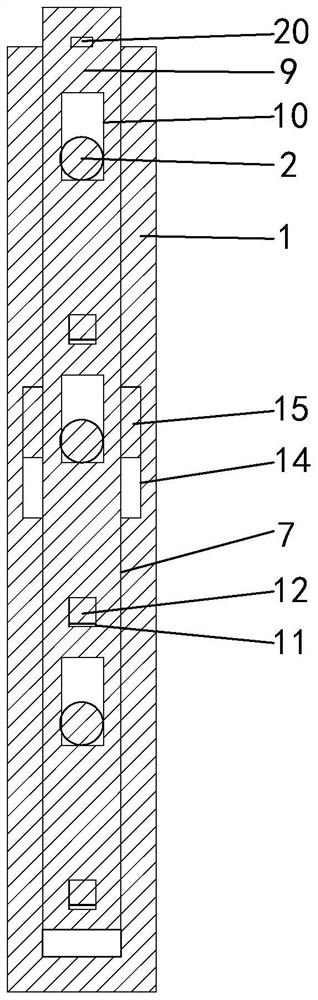

[0030] See Figures 1 to 4 As shown, a concrete prefabricated component that can be quickly connected includes a prefabricated component body 1. A number of steel bars 2 are pierced on both sides of the prefabricated component body 1. Several steel bars 2 on the same side are evenly arranged, and the steel bars 2 on both sides are mutually connected. Staggered, one side of the steel bar 2 is provided with an installation groove 3, and one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com