A Tension Sensor Used in Mechanical Manufacturing

A tension sensor, mechanical manufacturing technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problem of damage to the internal device of the sensor, achieve the effect of protecting safe use, convenient use and operation, and improving the accuracy of readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

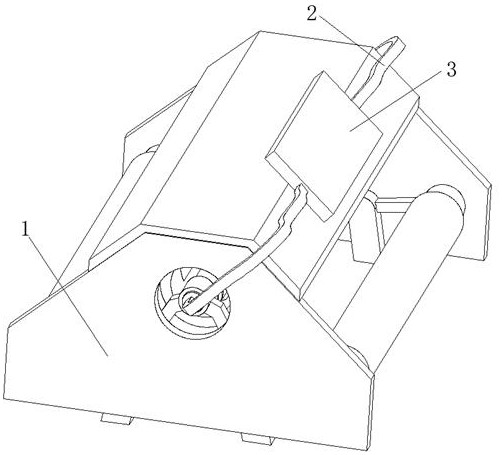

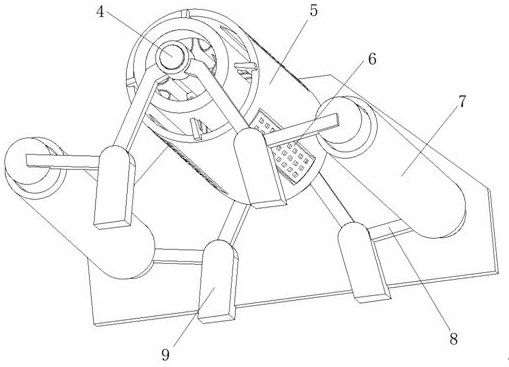

[0033] Such as Figure 1-3 As shown, the present invention provides a technical solution: a tension sensor for mechanical manufacturing, including an outer protection plate 1, the top of the outer protection plate 1 is fixedly connected with an operation panel 3, and the two sides of the operation panel 3 A transmission line 2 is fixedly connected to the army, a fixed base 9 is fixedly connected to the inner wall of the outer protective plate 1, a support frame 8 is fixedly connected to the top of the fixed base 9, and a second support frame 8 is rotatably connected to both sides of the support frame 8. Second shaft 7;

[0034] The top of the support frame 8 is fixedly connected with a first rotating shaft 4 , the outer surface of the first rotating shaft 4 is rotatably connected with a tension sensing unit 5 , and the outer surface of the tension sensing unit 5 is fixedly connected with a friction device 6 . The support frame 8 can be controlled by the staff manipulating the...

Embodiment 2

[0042] Such as Figure 4-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the tension sensing unit 5 includes a fitting shell 501, and the inner surface of the fitting shell 501 is fixedly connected with a side support rod 503, the Both ends of the side support rod 503 are fixedly connected with an inner pressure-sensitive housing 504 , and the bottom of the side support rod 503 is fixedly connected with a pressure bending bar 502 .

[0043] The outer surface of the pressure bending bar 502 runs through the inner pressure sensing shell 504, and the bottom of the pressure bending bar 502 is fixedly connected to the inner wall of the inner pressure sensing shell 504. A position flap 508 , a second through hole 507 is opened on the surface of the snap position flap 508 . When the external tension is too large, the internal pressure bending bar 502 can effectively transform the excessive pressure, reduce the pressure deformation of th...

Embodiment 3

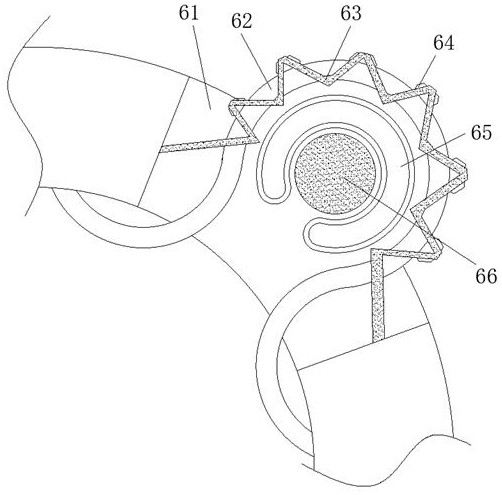

[0049] Such as Figure 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the internal induction device 506 includes a pressure-sensitive rubber block 5061, and the outer surface of the pressure-sensitive rubber block 5061 is fixedly connected with folded The clamping plate 5064 , the surface of the depression of the folding clamping plate 5064 is fixedly connected to the bottom end of the spring 505 , and the bottom of the folding clamping plate 5064 is fixedly connected with an induction post 5065 .

[0050] The sensor 5063 is fixedly connected to the end of the sensing rod 5065 away from the folding cardboard 5064, the inner wall of the pressure-sensitive rubber block 5061 is fixedly connected to the inner anti-seismic capsule 5062, and the inner anti-seismic capsule 5062 and the sensor 5063 Interphase extrusion fit. The induction post 5065 can limit the opposite end of the spring 505, and measure the tension thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com