Equipment for preventing line loosening and avoiding high-temperature burnout for artificial intelligence hardware

A technology of artificial intelligence and equipment, which is applied in the direction of connecting/disconnecting devices, circuits, electrical components, etc., can solve the problems of line burning, loosening, time-consuming and labor-intensive, etc., to prevent the line from loosening and avoid high-temperature burnout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

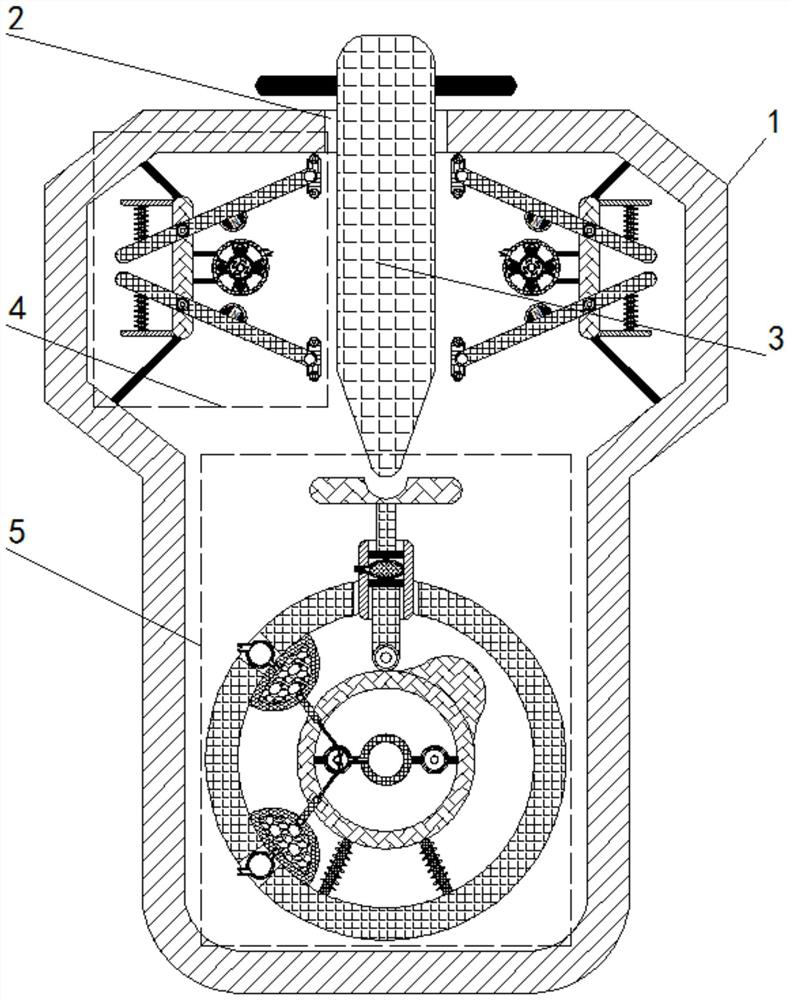

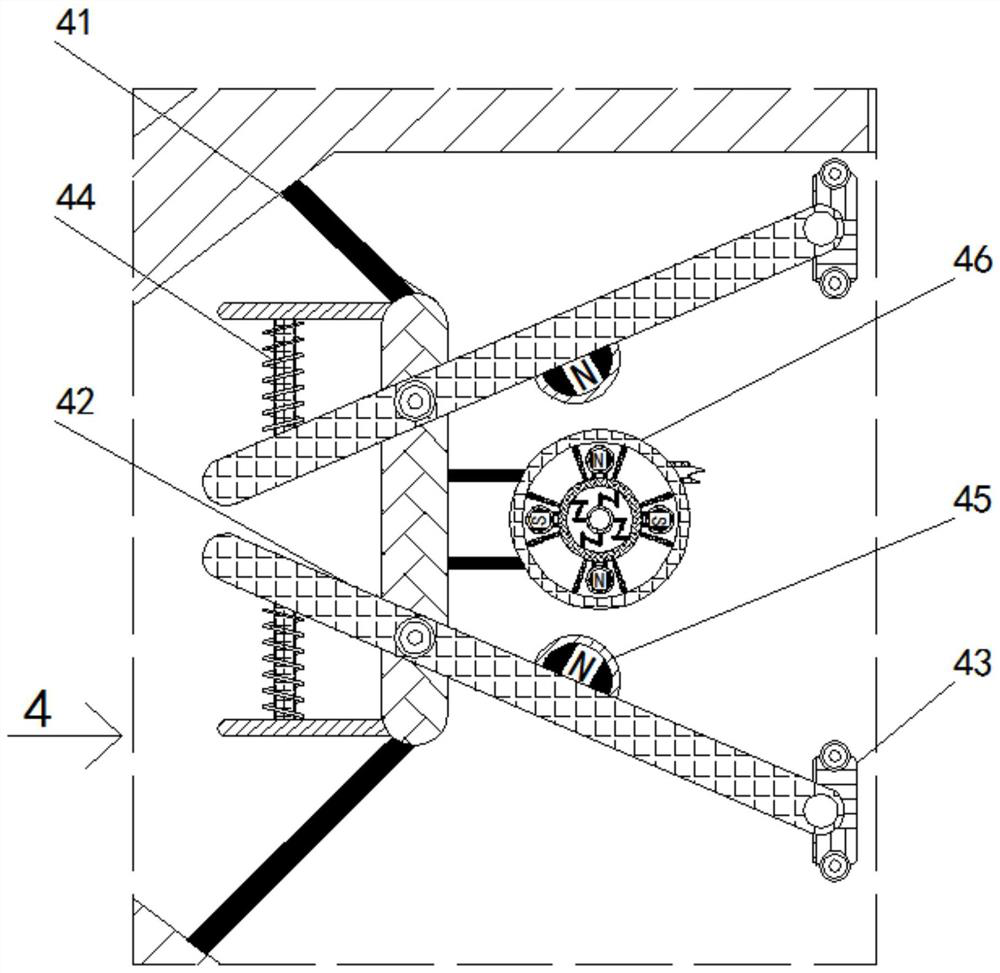

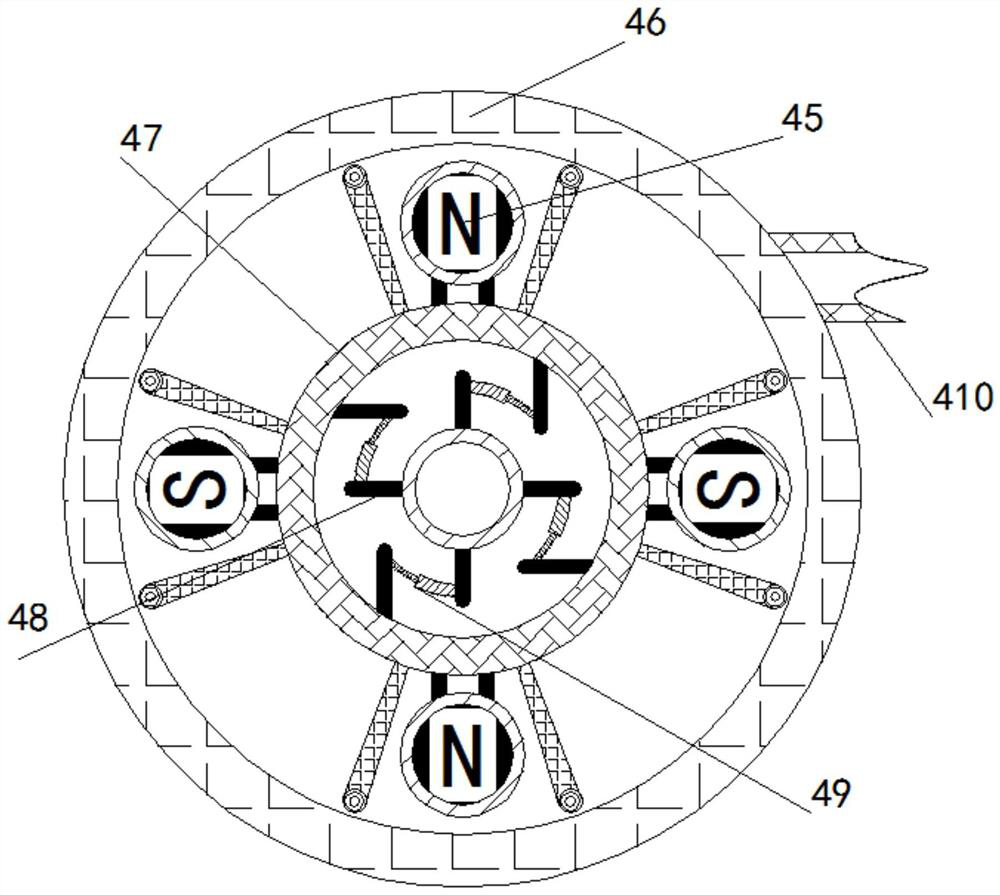

[0028] see Figure 1-4 , an artificial intelligence hardware device for preventing lines from loosening and avoiding high temperature burnout, including a main body 1 of an anti-dropping device, a through hole 2 is opened on the top of the main body 1 of the anti-dropping device, and a line 3 is slidably connected to the inside of the through hole 2, A fixing mechanism 4 is welded inside the main body 1 of the anti-dropping device, and a fixing frame 41 is welded inside the fixing mechanism 4. The front of the fixing frame 41 is rotatably installed with a rotating rod 42, and the right side of the rotating rod 42 is rotatably installed with a pressure plate 43. The rotating rod The top of the 42 is welded with an elastic rod 44, the bottom of the rotating rod 42 is welded with a magnet 45, the interior of the fixing mechanism 4 is welded with a fixed plate 46, the interior of the fixed plate 46 is rotatably installed with a rotor 47, and the inner wall of the rotor 47 is welded...

Embodiment 2

[0031] see Figure 1-2 And 4-6, an artificial intelligence hardware device for preventing circuit loosening and avoiding high temperature burnout, including an anti-dropping device main body 1, the top of the anti-dropping device main body 1 is provided with a through hole 2, and the internal sliding connection of the through hole 2 is connected. There is a circuit 3, a fixing mechanism 4 is welded inside the main body 1 of the anti-dropping device, a fixing frame 41 is welded inside the fixing mechanism 4, a rotating rod 42 is installed on the front of the fixing frame 41, and a pressure plate is installed on the right side of the rotating rod 42. 43, the top of the rotating rod 42 is welded with an elastic rod 44, the bottom of the rotating rod 42 is welded with a magnet 45, the interior of the fixing mechanism 4 is welded with a fixed plate 46, the interior of the fixed plate 46 is rotated and installed with a rotor 47, and the inner wall of the rotor 47 is welded There is ...

Embodiment 3

[0034] see Figure 1-6 , an artificial intelligence hardware device for preventing lines from loosening and avoiding high temperature burnout, including a main body 1 of an anti-dropping device, a through hole 2 is opened on the top of the main body 1 of the anti-dropping device, and a line 3 is slidably connected to the inside of the through hole 2, A fixing mechanism 4 is welded inside the main body 1 of the anti-dropping device, and an anti-burnout mechanism 5 is welded inside the main body 1 of the anti-dropping device.

[0035] Preferably, a fixing frame 41 is welded inside the fixing mechanism 4 , a rotating rod 42 is rotatably installed on the front of the fixing frame 41 , a pressure plate 43 is rotatably installed on the right side of the rotating rod 42 , and an elastic rod 44 is welded on the top of the rotating rod 42 . A magnet 45 is welded to the bottom of the rod 42 , a fixed plate 46 is welded to the inside of the fixing mechanism 4 , a rotor 47 is rotatably in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com