Paint spraying device for electric vehicle hub

A technology for electric vehicles and wheel hubs, applied in the direction of spraying devices, etc., can solve the problems of low painting efficiency, lack of wheel hubs, and large labor, and achieve the effect of improving painting efficiency and good painting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

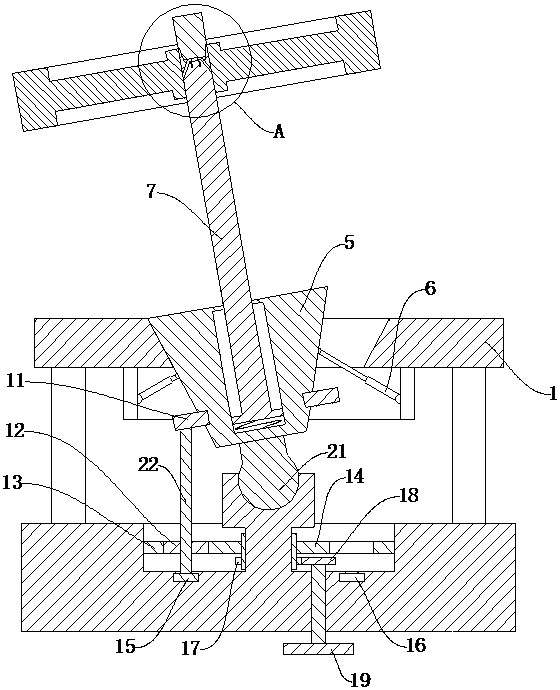

[0020] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

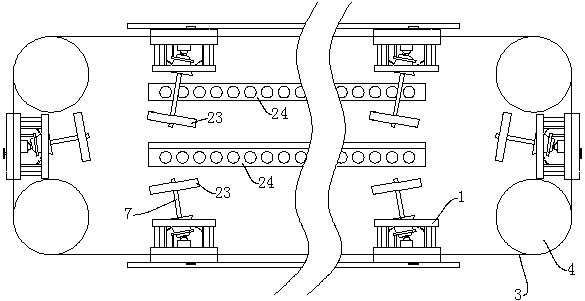

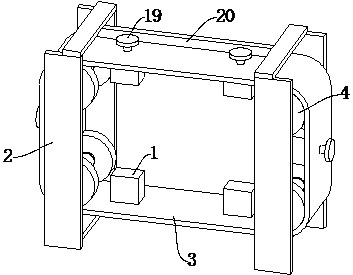

[0021] like Figure 1 to Figure 4 As shown, a painting device for an electric wheel hub provided by an embodiment of the present invention includes a conveying mechanism, a painting mechanism and a plurality of supports 1 arranged on the conveying mechanism.

[0022] Each support 1 is provided with a support assembly for fixing the hub 23 .

[0023] During the movement of the plurality of supports 1 driven by the conveying mechanism, the supports 1 can turn over 180 degrees and the support assembly can be in a swing state.

[0024] like figure 1 As shown, the painting mechanism includes two painting groups 24 fixedly installed on the conveying frame 2, and the two painting groups 24 are used for painting the two sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com