A solid waste harmless treatment equipment

A harmless treatment and equipment technology, applied in the direction of lighting and heating equipment, incinerators, furnaces, etc., can solve the problems of poor economy, achieve the effect of reducing energy consumption and better heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

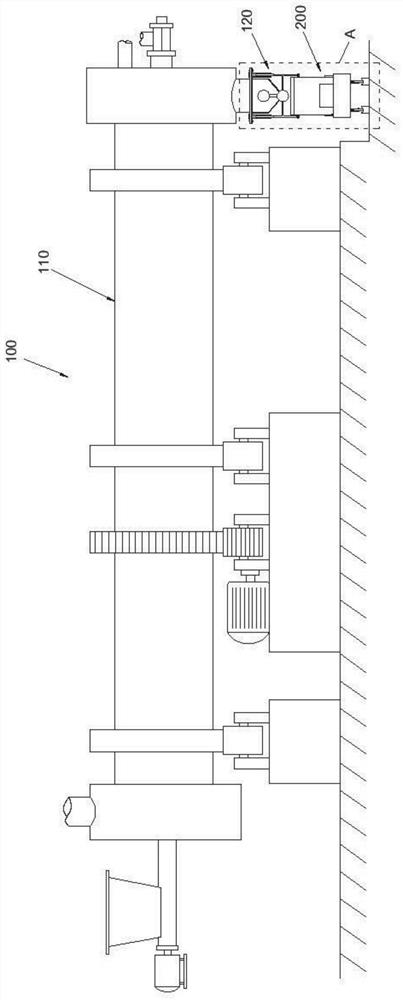

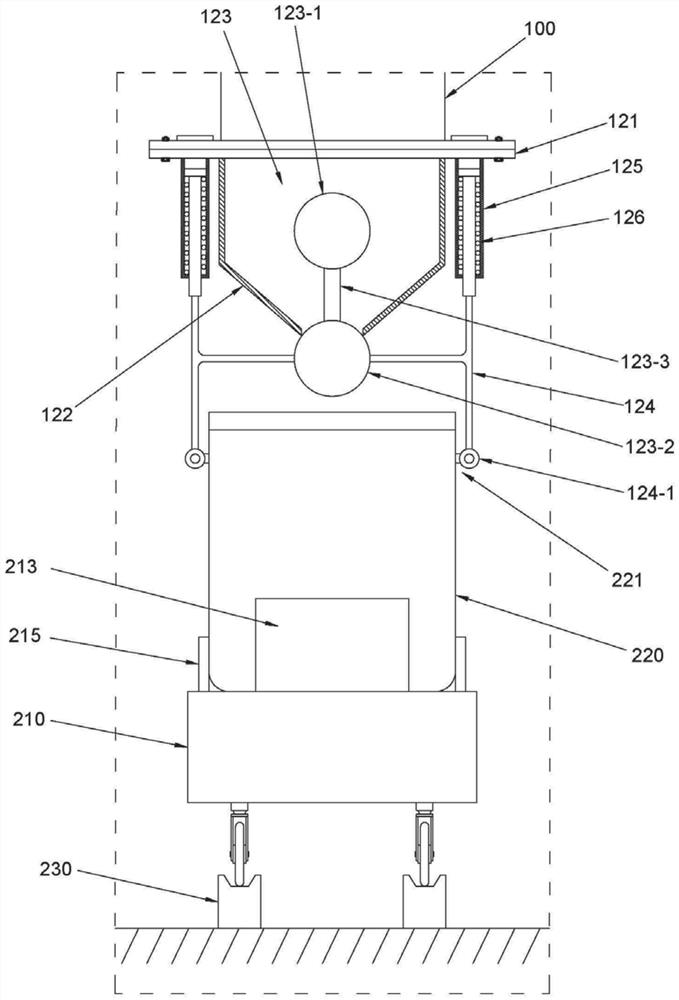

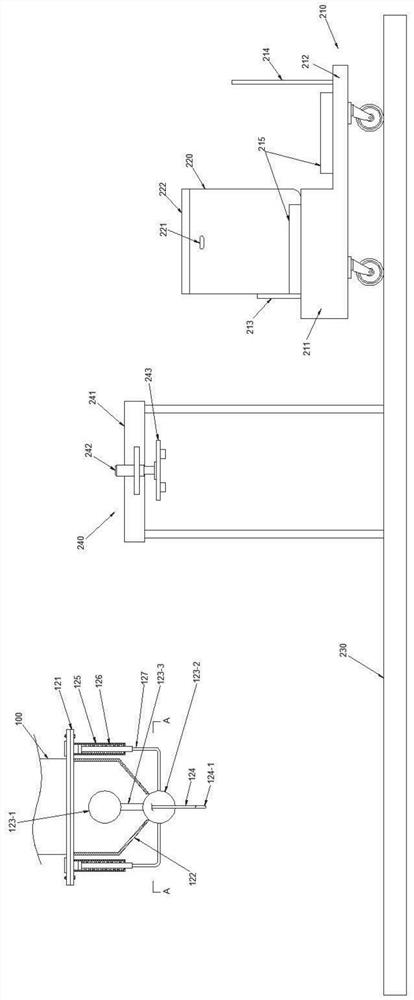

[0030] Such as Figure 1 to Figure 5 As shown, the solid waste harmless treatment equipment in this embodiment includes a pretreatment assembly 100, a transfer assembly 200, an electric furnace, a molding assembly and an exhaust gas treatment equipment;

[0031] The pretreatment assembly 100 includes a rotary kiln 110 and a storage bin 120. The storage bin 120 includes a flange 121, a bin body 122, a closure 123, a T-shaped bar 124, a sleeve 125, a spring 126 and an L-shaped bar 127. The body 122 is connected to the discharge port of the rotary kiln 110 through the flange 121, and the closure 123 includes an inner seal body 123-1, an outer seal body 123-2 and a connecting rod 123-3, and the inner seal body 123-1 and the outer seal body The body 123-2 is a hollow ball, the inner sealing body 123-1 is located inside the warehouse body 122, the outer sealing body 123-2 is located outside the warehouse body 122, and both the inner sealing body 123-1 and the outer sealing body 123-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com