Automatic multi-heat-pipe vacuum quantitative working medium filling system

A multi-heat pipe, automatic metering technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as affecting the residual amount of air in the heat pipe and affecting the degree of gas exhaustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

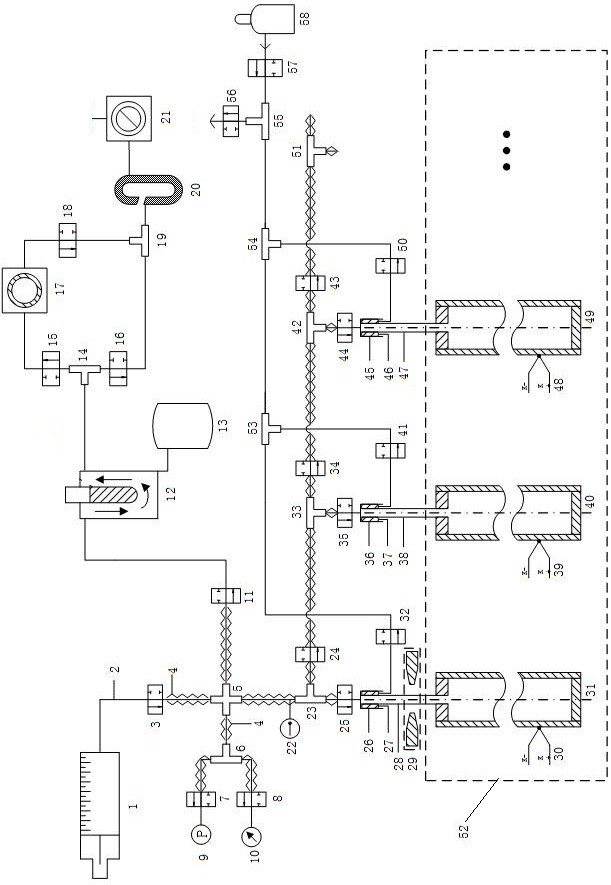

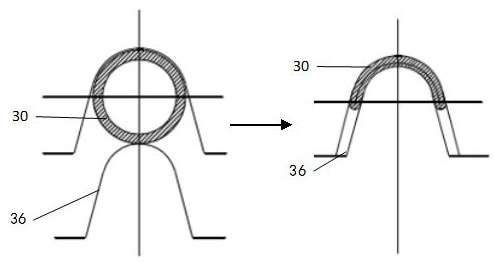

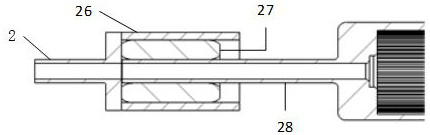

[0040] Such as Figure 1~4 As shown, an automatic multi-heat pipe vacuum quantitative working medium filling system includes an automatic metering pump, pipeline and its control system, temperature control device, pressure measurement system, vacuum system, and inflatable sealing ring system.

[0041] The four directions of up, down, left, and right are used in describing the pipeline connection below. But please note that the specific location of each device depends on the actual situation.

[0042] The automatic metering pump has different options according to different heat pipes. For different heat pipes, the optimal filling rate can be obtained through their respective optimal liquid filling rates. The research found that the actual filling error of the heat pipe does not exceed 0.5% to 2% of the optimal filling amount, and the performance of the heat pipe remains basically unchanged. For different heat pipes, metering pumps with different precisions are used to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com