Clothing structure pattern making method

A technology of clothing and bust, applied in the field of clothing production, can solve the problems of cuff position deviation, error, clothing cannot fit the human body structure, etc., and achieve the effect of improving the production range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] S1: Bust measurement for front and back pieces

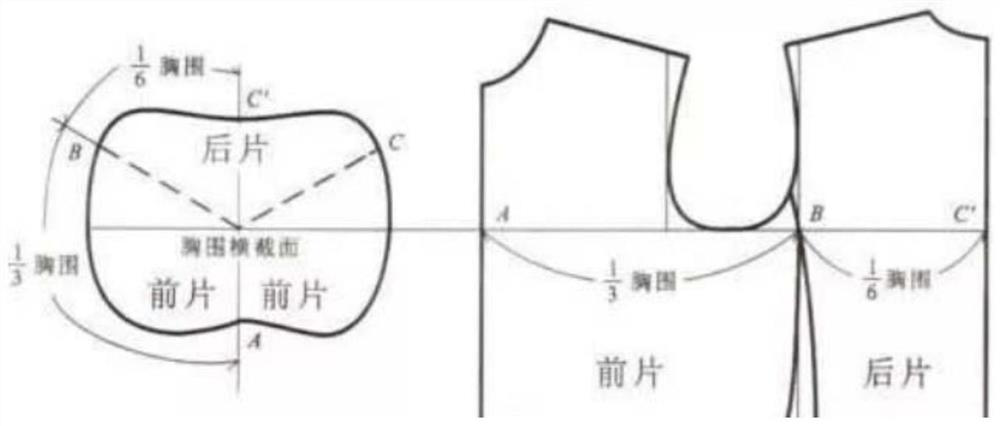

[0048] Divide the cross-section of the human bust into three equal parts, generate three points A, B, and C, and divide them vertically through these three points to generate the corresponding clothing plane drawing. The bust of the back piece and the back piece each account for 1 / 3 of the bust measurement, and the back piece is divided into two parts vertically according to C, and the bust measurement of each piece accounts for 1 / 6 of the bust measurement; (such as figure 1 shown)

[0049] S2: Chest width, back width and armhole measurement plate making

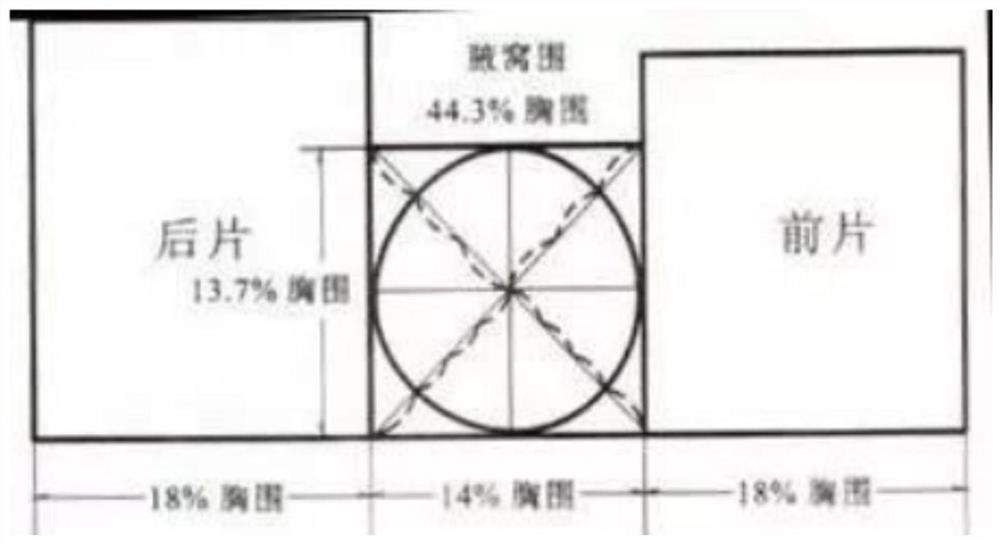

[0050] a. Chest width, back width, and armholes are measured and analyzed through sampling of normal human bodies. The armholes are designed according to the cross-sectional shape of the human armpit, and the proportion of the chest circumference is:

[0051] Chest width = 18% of tight bust, back width = 18% of tight bust, armpit width = 14% of tight bust, armpit dept...

Embodiment 2

[0075] S1: Bust measurement for front and back pieces

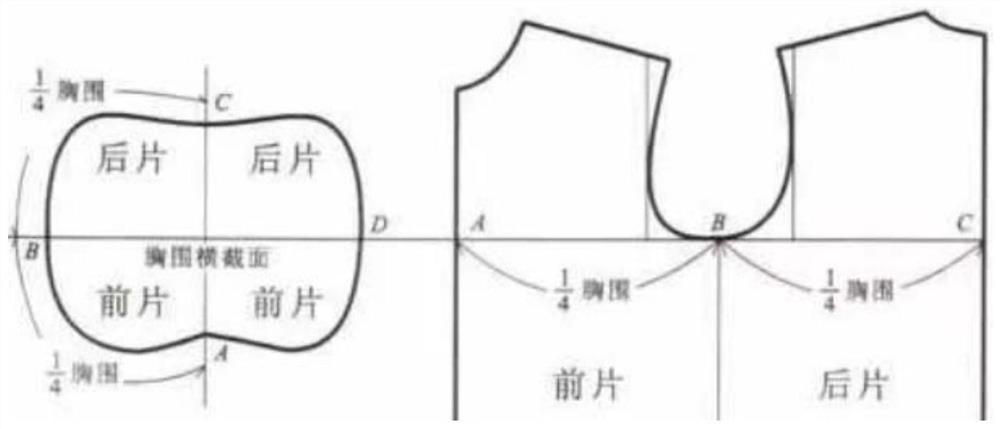

[0076] Divide the cross-section of the human bust into four equal parts, generate three points A, B, C, and D, and divide them vertically through these three points to generate the corresponding clothing plane drawing. The bust of the front piece and the back piece each account for 1 / 4 of the bust. (Such as figure 2 shown)

[0077] S2: Chest width, back width and armhole measurement plate making

[0078] a. Chest width, back width, and armholes are measured and analyzed through sampling of normal human bodies. The armholes are designed according to the cross-sectional shape of the human armpit, and the proportion of the chest circumference is:

[0079] Chest width = 18% of tight bust, back width = 18% of tight bust, armpit width = 14% of tight bust, armpit depth = 13.7% of tight bust and armpit circumference = 44.3% of tight bust

[0080] b. The specification of the bust is the calculation formula of the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com