Corrugated armoring machine

A corrugated armor and sliding sleeve technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of increasing demand for circular armored cables, increasing production costs, and small production scope, and achieving a one-time pass rate Guarantees, saves energy, and expands the scope of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

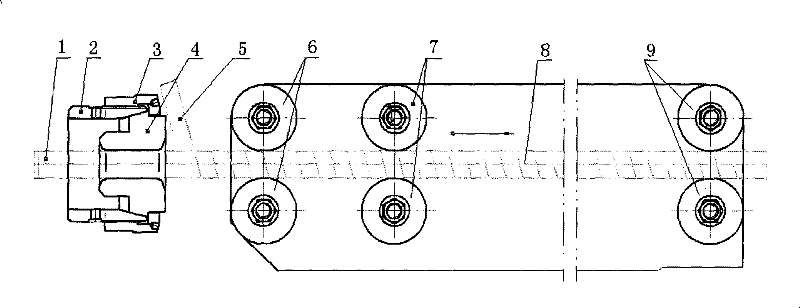

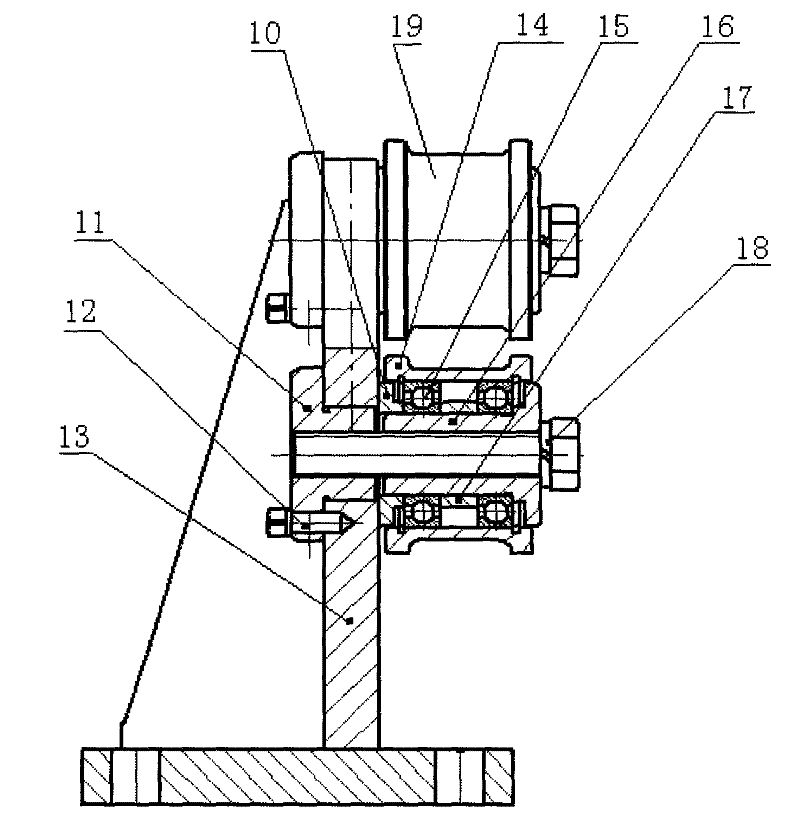

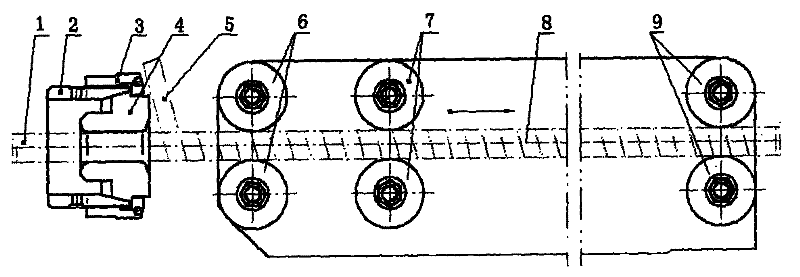

[0013] Such as figure 1 As shown, the corrugated armoring machine includes a shaping mechanism, a first rolling sleeve shaping die 6, a second rolling sliding sleeve shaping die 7 and a third rolling sliding sleeve shaping die 8, and the qualitative mechanism is installed in the cable running direction of the corrugated wrap outlet port 5 In front of the front, the first rolling sleeve shaping die 6, the second rolling sliding sleeve shaping die 7 and the third rolling sliding sleeve shaping die 8 are arranged behind the cable running direction of the corrugated package outlet port 5, wherein the first rolling sliding sleeve shaping The mold 6 and the second rolling sliding sleeve shaping mold 7 are close to the corrugated wrapping position 5.

[0014] The shaping mechanism includes a positioning sliding sleeve 2, a locking sleeve 3 and a shaping die 4. The shaping die 4 has a shaping round hole through which the cable 1 passes. The inner surface of the sleeve 3 cooperates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com