Automatic grading mechanism for ball head and ball socket of engine

An engine and head ball technology, which is applied in the field of automatic detection and classification of engine ball head and ball socket, can solve the problems of personnel judgment deviation and low classification detection efficiency, and achieve the goal of eliminating manual deviation, improving detection accuracy and improving detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

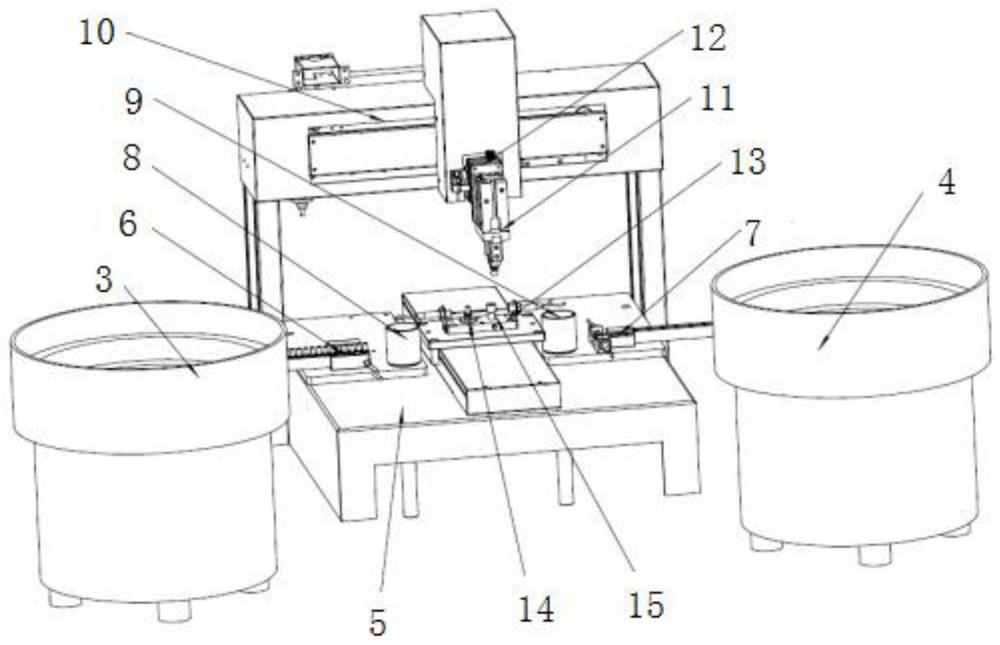

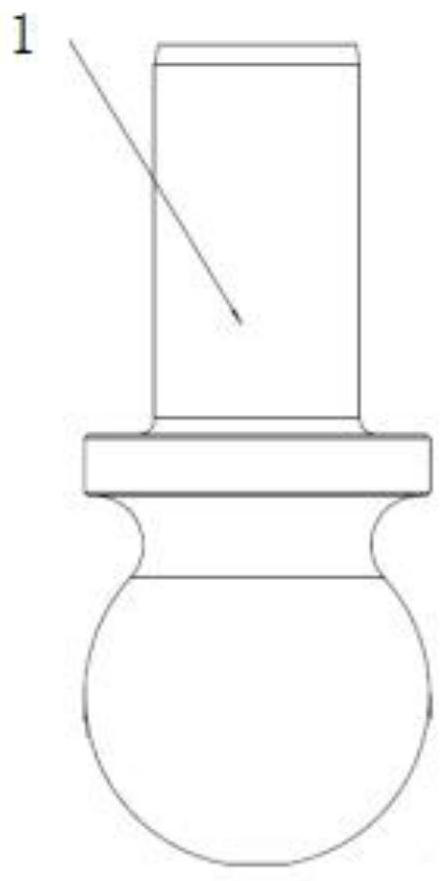

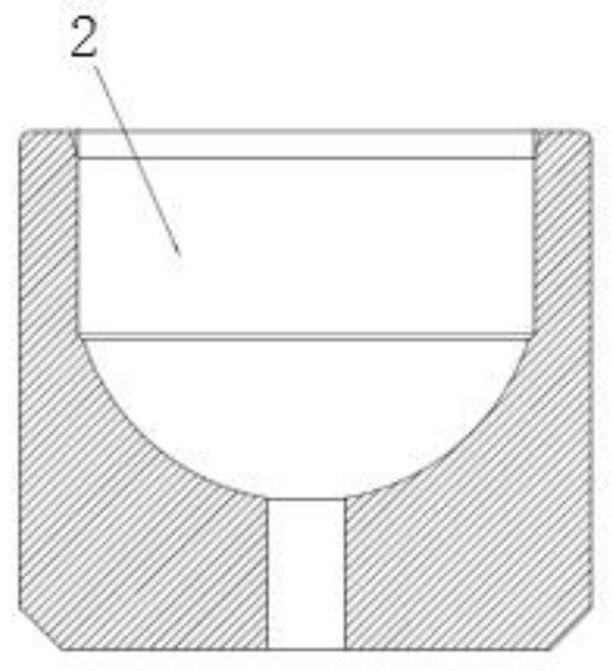

[0036] refer to Figure 1-17 , an engine ball head and socket automatic gearing mechanism, comprising a ball head vibration plate 3, a ball socket vibration plate 4, a gearing platform 5, a ball head feeding mechanism 6, a ball socket feeding mechanism 7, a large ball head ball socket The blanking mechanism 8, the small ball socket blanking mechanism 9, the transfer mechanism 10, the ball socket clamping mechanism 11, the buffer connection mechanism 12 and the ball socket classification detection mechanism 13, wherein:

[0037] The binning platform 5 is fixed to the external fixing part, the ball head vibrating plate 3 for automatic feeding of ball head 1 is fixedly connected to the external fixing part, and the ball socket vibration plate for automatic feeding of ball socket 2 is fixedly connected to the external fixing part The disk 4 and the ball head feeding mechanism 6 are fixed to the classification platform 5 by bolts. The outlet of the ball head vibrating disk 3 corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com