System and method for deboning a poultry leg part

A technology for legs, poultry, applied in the field of deboning poultry thighs, which can solve the problems of bone fragmentation, difficulty in achieving the accuracy of gripper or diaphragm movement, force accuracy on the bone, incomplete harvesting of meat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

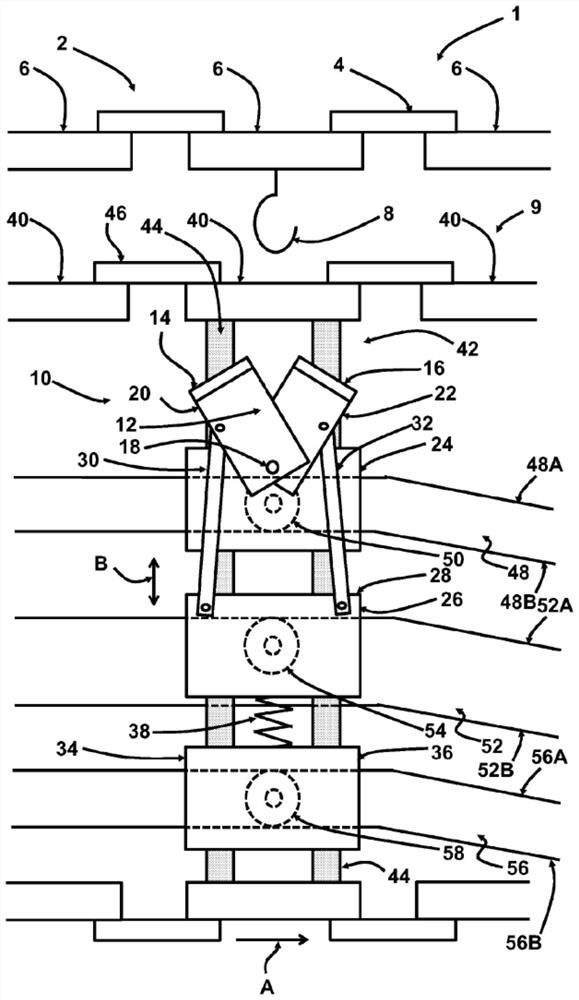

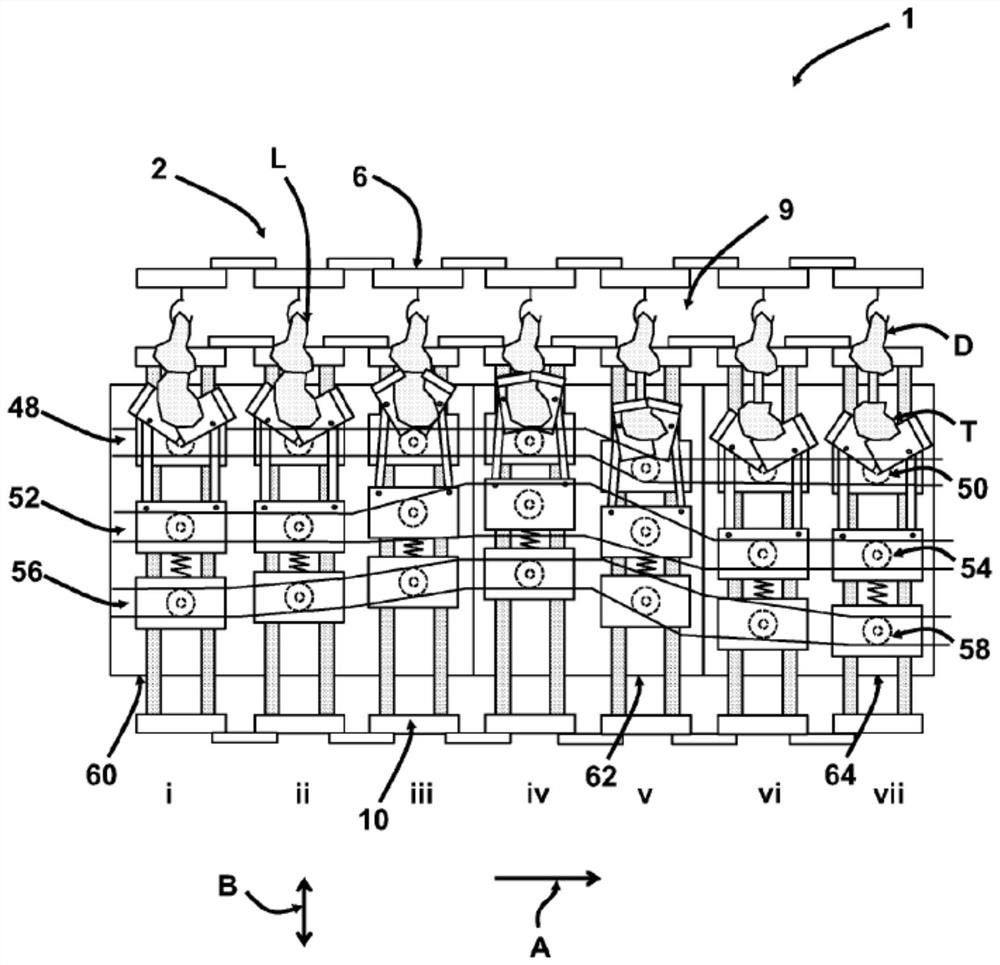

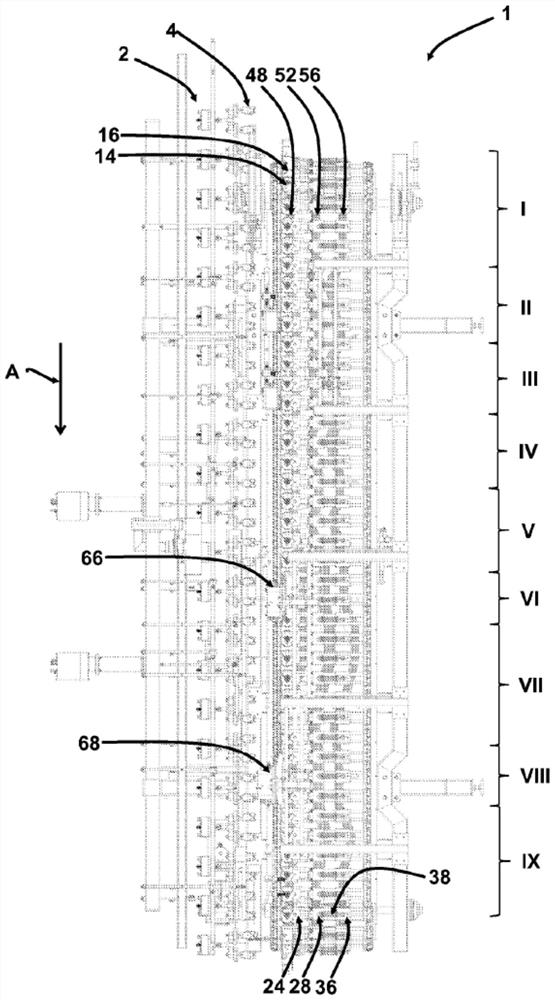

[0039] figure 1 A schematic diagram of a system 1 for deboning a poultry leg is shown, wherein in particular a poultry leg is a leg comprising at least one bone and meat surrounding the bone, such as a poultry leg comprising a thigh and a lower leg , or poultry thigh or poultry lower leg.

[0040] The system 1 comprises a conveying unit 2 arranged to suspend the legs of birds and for conveying the legs of birds in a conveying direction A along a conveying path. In this example, the conveyor unit 2 is an overhead conveyor unit. The conveyor unit 2 is here a conveyor chain 4 . The transport unit 2 comprises a plurality of shackles 6 for hanging the legs of the birds. The bird's leg can be suspended from the hook 8 of the shackle 6 eg by the ankle joint of the leg.

[0041] System 1 also includes a bone removal system 9 comprising one or more bone removal units 10 . The bone removal unit 10 comprises a gripper 12 arranged for grasping the meat surrounding the bone. Here, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com