Three-dimensional bag attaching combination template and bag attaching method

A technology of combining templates and sticking pockets, applied in textiles and papermaking, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of inconsistency in seaming folding, irregular stitches, low production efficiency, etc., and achieve a fixed folding amount. , the effect of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

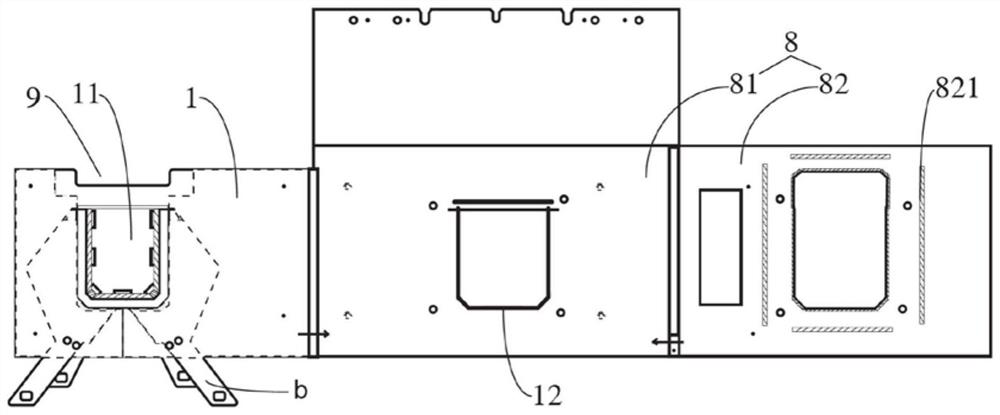

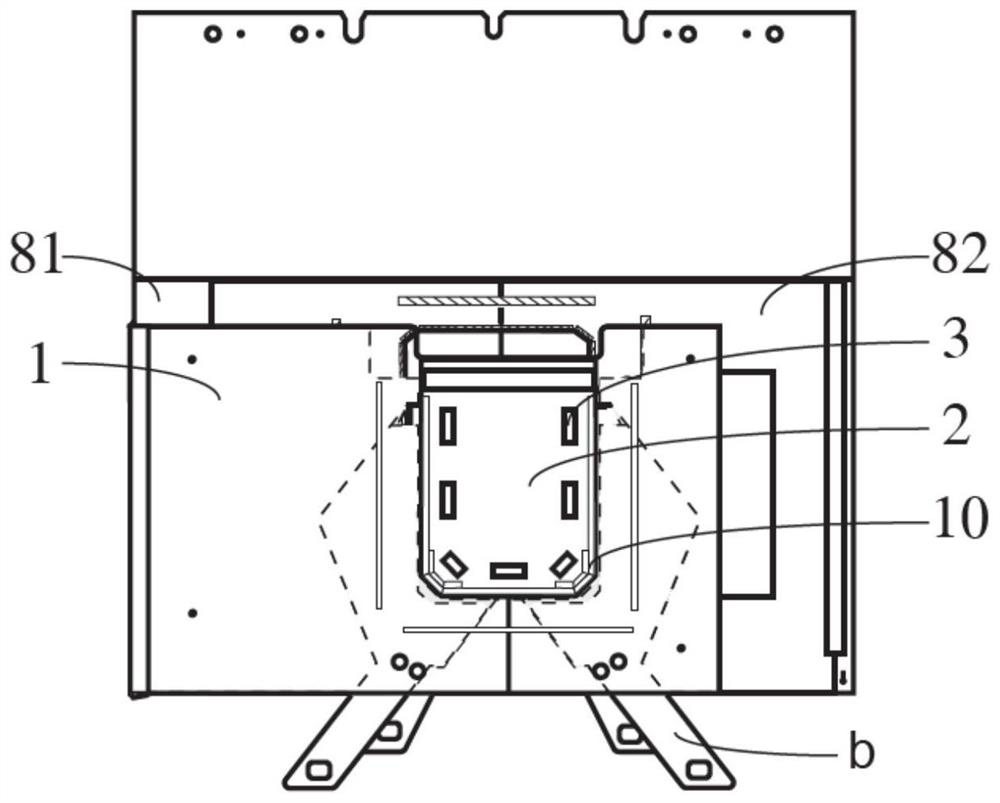

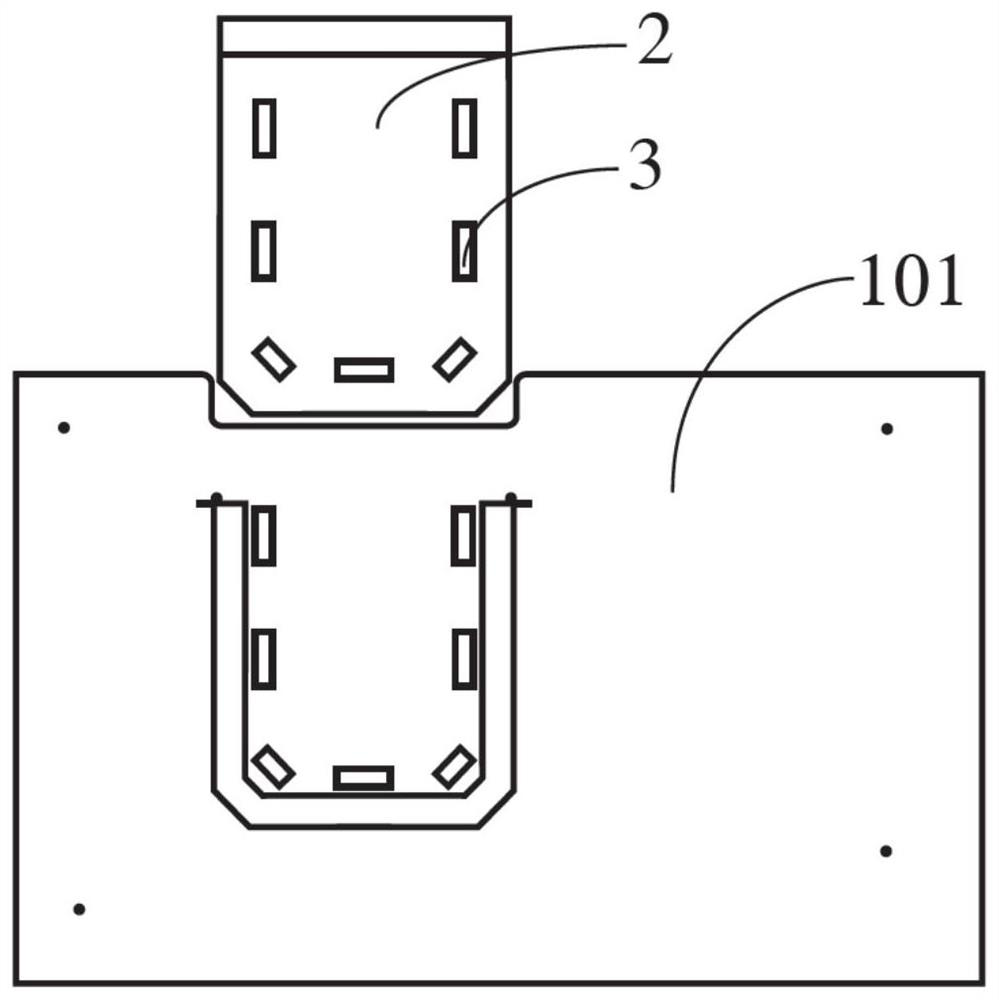

[0051] Such as Figure 3-6 As shown, the three-dimensional patch bag combination template of the embodiment includes: a cover plate 1, the first plate surface of the cover plate 1 is provided with a pressing plate 2, the top edge of the pressing plate 2 is connected with the cover plate 1 through an adhesive strip, and the pressing plate 2 can be glued around it. The edge is turned over, and the pressure plate 2 and the cover plate 1 are provided with a magnetic piece 3 that is magnetically attracted to each other, and is used to clamp the sewing edge of the outer layer of the bag; the second plate surface is provided with a positioning groove 11 that is depressed along the thickness direction of the plate for positioning. The edge of the groove bottom surface of the groove 11 is provided with a U-shaped sewing groove 12 that runs through the thickness of the cover plate 1; The side grooves and the hemming grooves between the side grooves of the bag and the bottom grooves of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com