Production process change risk assessment method and system

A technology for production process and risk assessment, applied in the field of production safety management, can solve problems such as inaccurate assessment results, difficulty in targeted management and control of process change risks, and achieve the goal of overcoming inaccurate assessment results, improving the quality of production control and accurate quantitative assessment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementations of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific implementation manners described herein are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

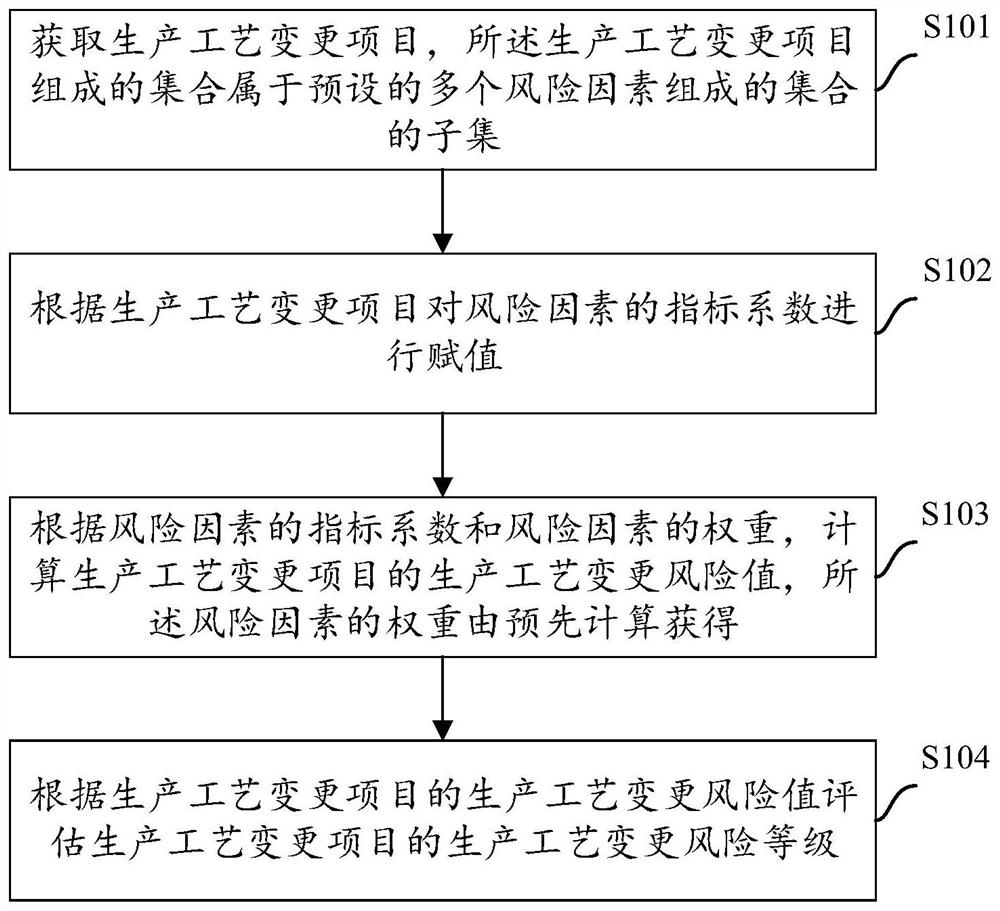

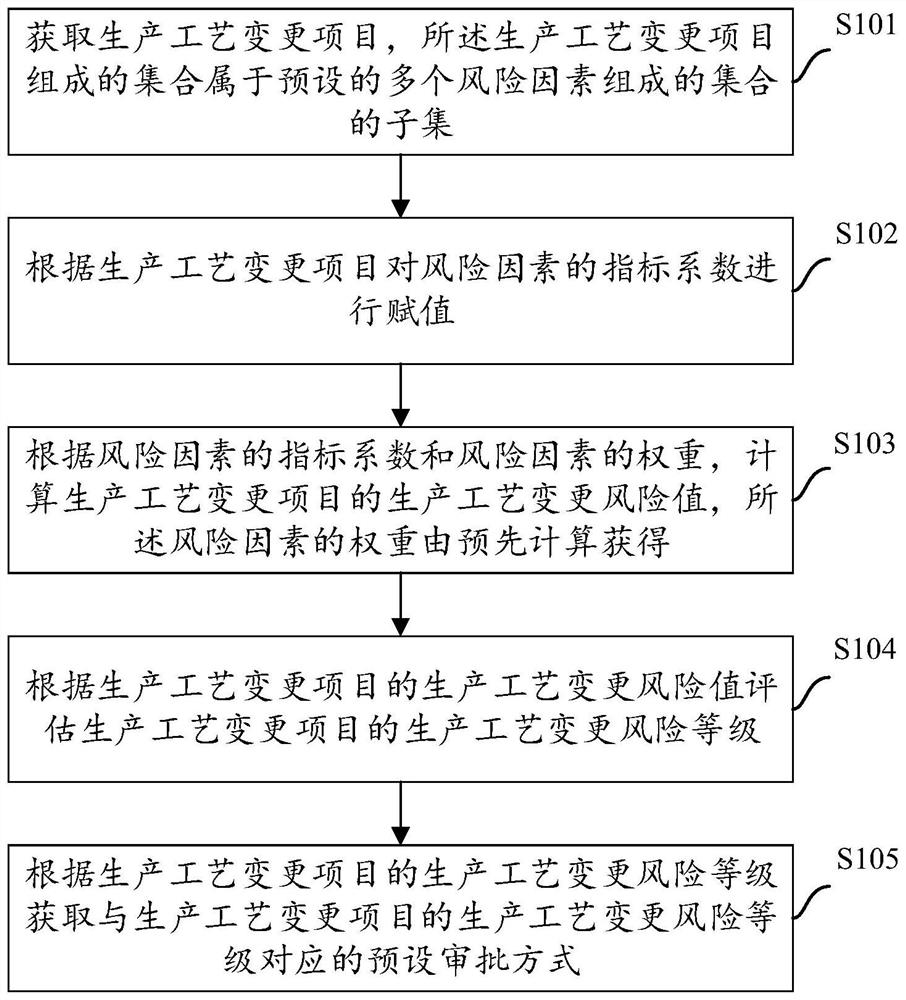

[0062] figure 1 It is the method flow of the embodiment of the present invention Figure 1 , the method includes:

[0063] Step S101, obtaining a production process change item, where the set composed of the production process change item belongs to a subset of a set composed of a plurality of preset risk factors;

[0064] In this embodiment, the preset set of multiple risk factors is also referred to as a risk factor index system. The above-mentioned multiple risk factors are specifically designed for the change of the production process, and the multiple risk factors may be risk factors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com