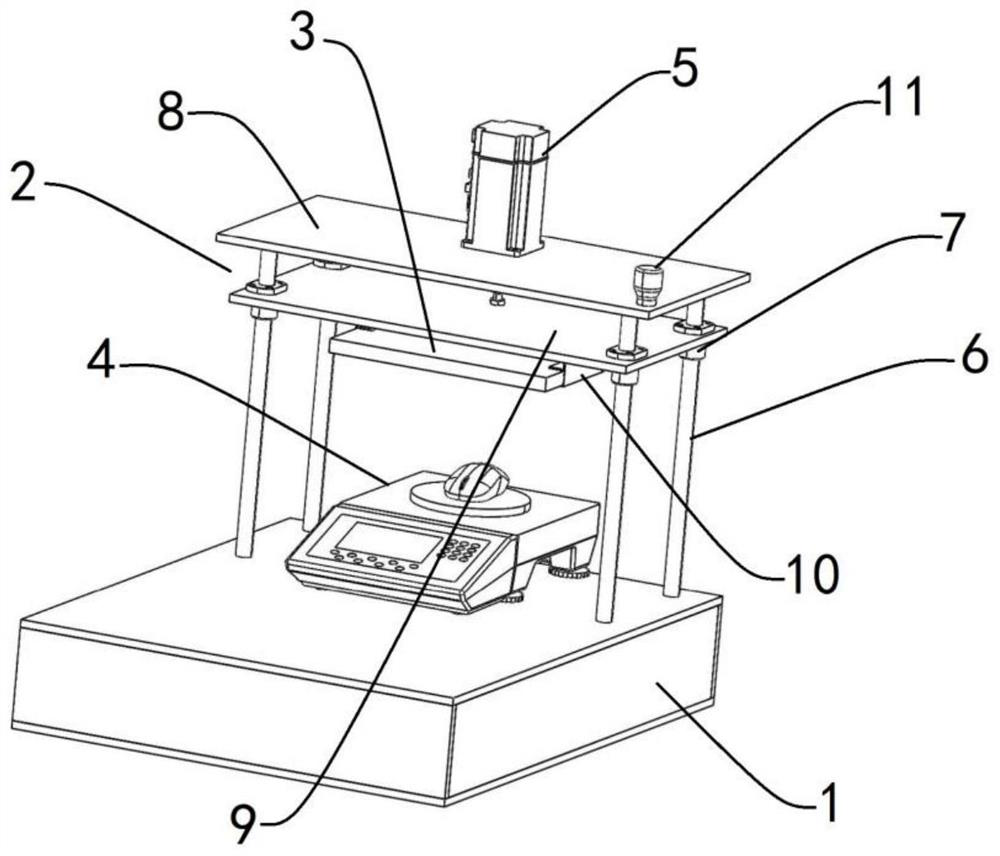

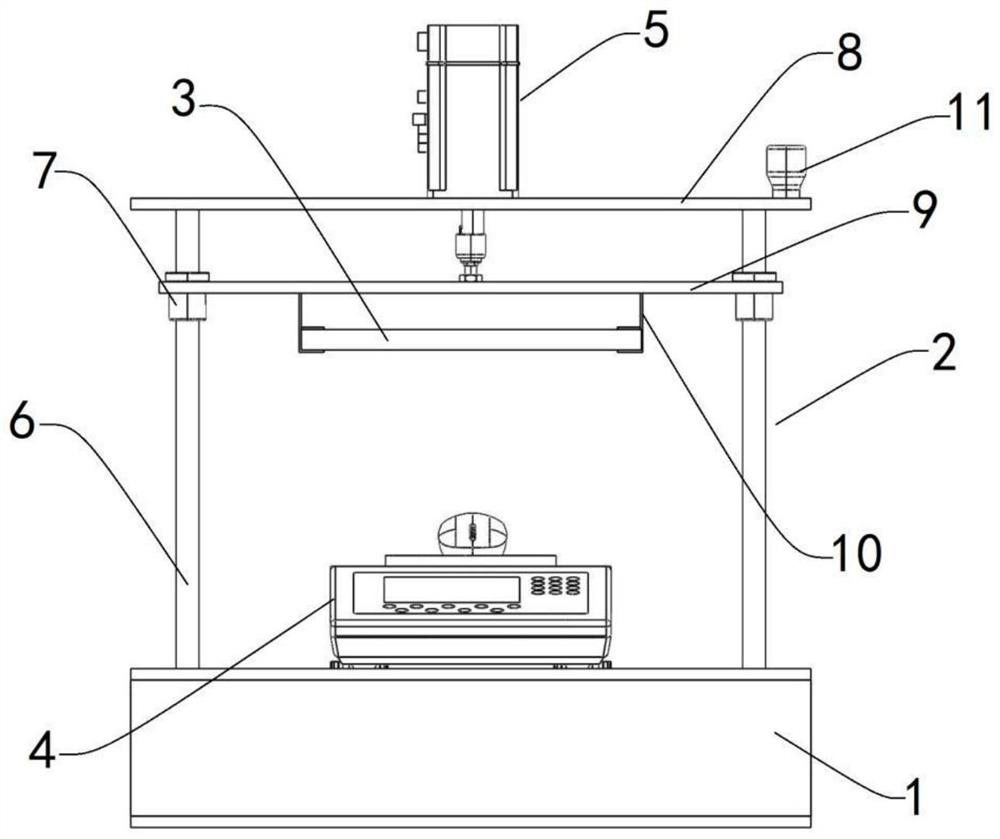

Electronic product screw locking detection device and detection method thereof

A technology for electronic products and detection devices, which is applied in the field of electronic product lock screw detection devices, and can solve problems affecting product quality, missing locking screws, lack of locking screws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The electronic control box is powered on and opened, and a number of flawless complete products are placed in the feeding tray of the electronic scale manually or mechanically, and the weighing value of the electronic scale of each sample product is recorded one by one, and then dropped to the specified height by the magnet Finally, get the weighing value after the magnet drops again, and subtract the second weighing value from the first weighing value to get a judgment value range with very small error, which can be obtained through the detection of the sample. When the magnet is gradually lowered, the weighing value of the sample is steadily reduced.

[0031] After obtaining the judgment value, the product to be tested is placed on the electronic scale by means of manual loading or automatic loading and unloading means such as manipulators, and the original weighing value of the product to be tested is recorded, and then the magnet is controlled by the magnet lifting f...

Embodiment 2

[0034] The electronic control box is powered on and opened, and a number of flawless complete products are placed in the feeding tray of the electronic scale manually or mechanically, and the weighing value of the electronic scale of each sample product is recorded one by one, and then dropped to the specified height by the magnet Finally, get the weighing value after the magnet has dropped again, and subtract the second weighing value from the first weighing value to get a judgment value with a very small error, which can be obtained through the detection of the sample. When gradually decreasing, the weighing value of the sample is steadily decreasing.

[0035] After the determination value is obtained, the product to be inspected is placed on the electronic scale manually or by a robot, and the original weighing value of the product to be inspected is recorded, and then the magnet is controlled to drop at a uniform speed through the magnet lifting frame, and when the magnet i...

Embodiment 3

[0037] The electronic control box is powered on and opened, and a number of flawless complete products are placed in the feeding tray of the electronic scale manually or mechanically, and the weighing value of the electronic scale of each sample product is recorded one by one, and then dropped to the specified height by the magnet Finally, get the weighing value after the magnet drops again, and subtract the second weighing value from the first weighing value to get a judgment value range with very small error, which can be obtained through the detection of the sample. When the magnet is gradually lowered, the weighing value of the sample is steadily reduced.

[0038] After the determination value is obtained, the product to be inspected is placed on the electronic scale manually or by a robot, and the original weighing value of the product to be inspected is recorded, and then the magnet is controlled to drop at a uniform speed through the magnet lifting frame, and when the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com