Heat-not-burn baking device

A heat-not-burn, roasting device technology, applied in tobacco and other directions, can solve the problems of affecting taste, long preheating time, long preheating, etc., to avoid high temperature steam scalding, reduce preheating time, reduce The effect of heat time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

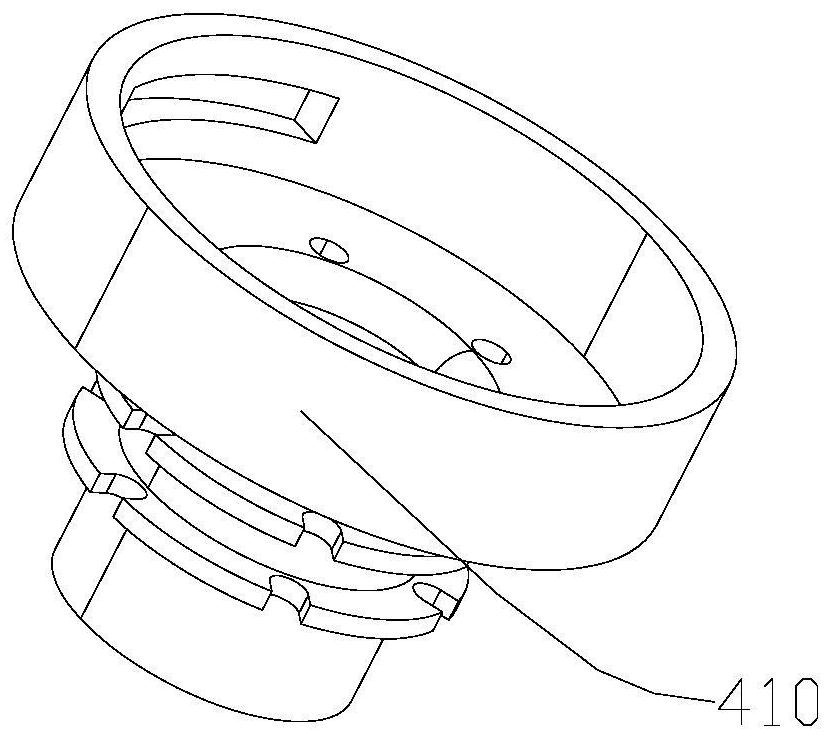

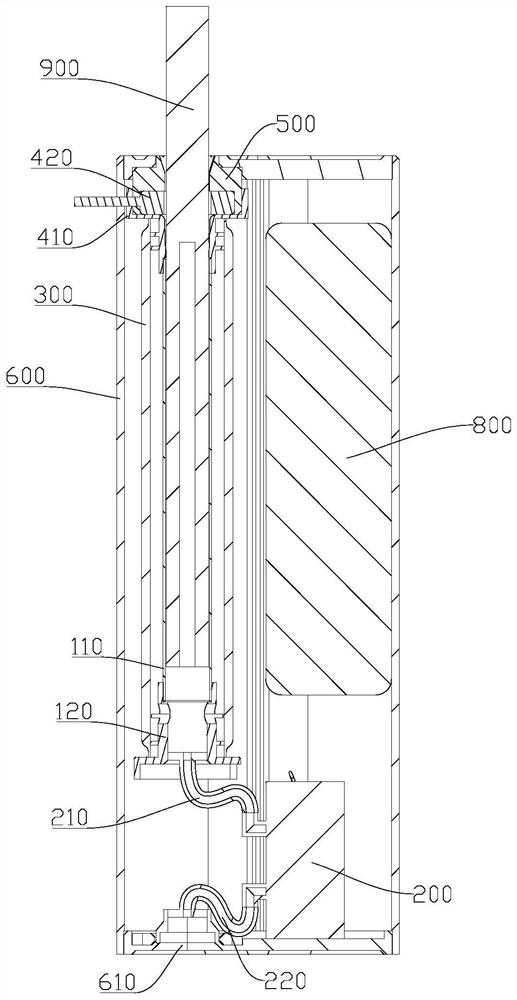

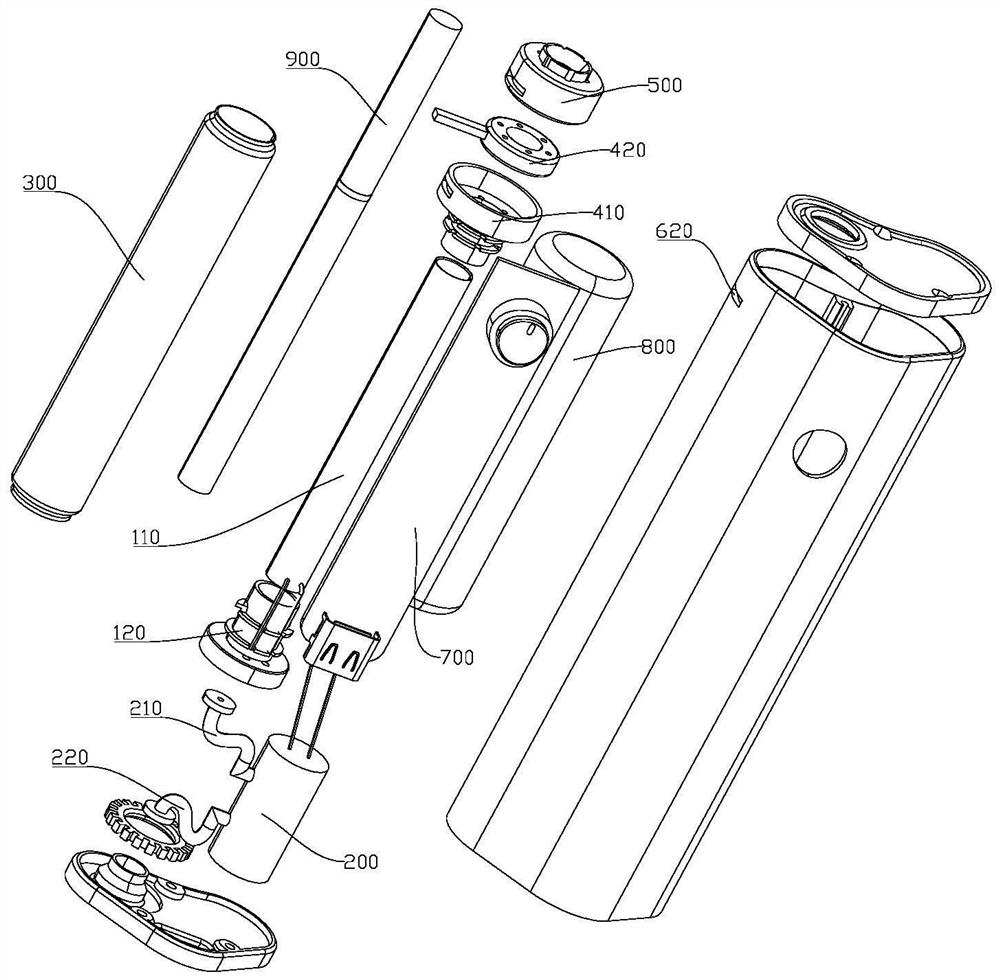

[0027] Please refer to Figure 1-Figure 6 , a heat-not-burn roasting device, comprising: a roasting assembly, the inserting channel 111 for inserting the heat-not-burning roasting cigarette 900 is arranged in the roasting assembly, and the roasting assembly is equipped with an air inlet connected to the inserting channel 111 121 and the air extraction hole 122; the negative pressure mechanism 200 is connected to the air extraction hole 122. When the negative pressure mechanism 200 works, the airflow flowing out from the air extraction hole 122 is generated in the insertion channel 111.

[0028] A negative pressure mechanism 200 is set at the bottom of the baking assembly to extract high-temperature water vapor, thereby reducing the preheating time and avoiding the problem of high-temperature water vapor scalding the mouth; and because the preheating time is reduced, not only does the user not need to wait for a long time , and save electric energy, so that the heat-not-burn ro...

Embodiment 2

[0040] The difference from the heat pipe 110 which adopts circumferential heating in the first embodiment is that:

[0041] The baking assembly includes a cannula, a heating element and a bracket 120. The insertion channel 111 is formed by the insertion tube. The bracket 120 is connected to the bottom of the insertion tube. The heating element is passed through the bracket 120 and extends into the insertion channel 111.

[0042] The intubation tube only plays the role of supporting and limiting, and is used for inserting the heat-not-burn tobacco branch 900, and the heating element is inserted into the heat-not-burn tobacco branch 900 for heating.

[0043] It can be understood that since the cannula does not take on the role of heating, the air inlet hole 121 and the air suction hole 122 can be configured on the cannula or the bracket 120 .

Embodiment 3

[0045] The difference from the first embodiment is that the adjusting member 420 is driven to rotate by electric drive.

[0046] Simply, the outer peripheral wall of the adjustment member 420 is provided with teeth, the motor drives the gear to rotate, and the gear meshes with the adjustment member 420 . Understandably, the motor is connected to the control circuit board 700 .

[0047] It should be noted that if there is a directional indication (such as up, down, left, right, front, back...) in the embodiment of the present invention, the directional indication is only used to explain the position in a certain posture (as shown in the accompanying drawing). If the specific posture changes, the directional indication will also change accordingly. In general, the direction of the mouthpiece relative to the base is the up, or top.

[0048] In summary, the present invention provides a heat-not-burn baking device. A negative pressure mechanism is installed at the bottom of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com