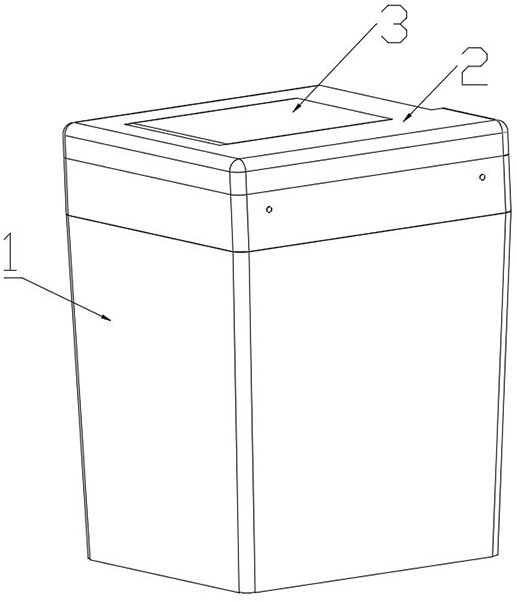

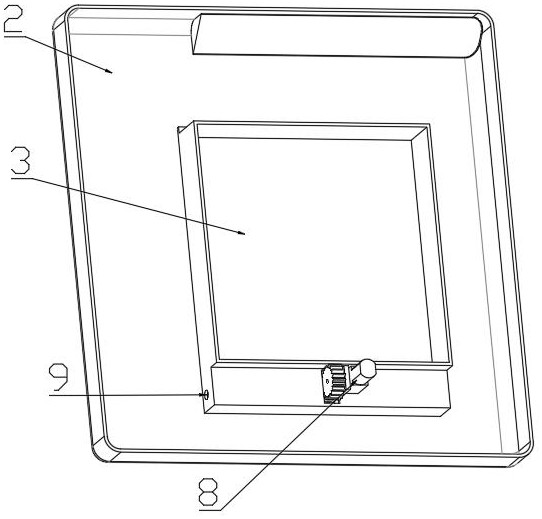

Waste collecting and packaging device

A waste collection and bagging device technology, which is applied in packaging, transportation packaging, garbage collection, etc., can solve the problems of troublesome cleaning personnel and low intelligence of garbage bins, and achieve the effect of preventing secondary infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

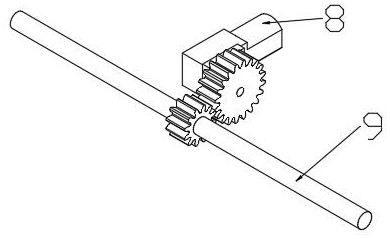

[0064] Implementation case 1: bag support stage: the riser a504 will continue to move, and pass through the through hole a515 on the riser b513 to contact the garbage bag 802. When the hook a512 contacts the garbage bag 802, the first motor 502 stops rotating. The second motor 507 turns on and drives the eccentric wheel 510 to rotate, so that the eccentric wheel 510 rotates in the groove a509 on the bag-grabbing plate 511, thereby driving the bag-grabbing plate 511 to move downward as a whole. Move down, so that the hook a512 enters the through hole e803 of the garbage bag 802, the second motor 507 continues to rotate, the hook a512 is driven by the bag grabbing plate 511 to move upwards, so that the hook a512 hooks the garbage bag 802 through the through hole e803, the second The motor 507 stops moving, and the first motor 502 reverses, driving the bagging device 5 to move to the left, so that the left side of the garbage bag 802 breaks through the rubber stopper 805 on the ro...

Embodiment example 2

[0065] Implementation case 2: bag support stage: the vertical plate a504 will continue to move, and the vertical plate a504 will slowly approach the vertical plate b513, and the guide rod b522 will approach the stopper 521, and since the stopper 521 is fixed with an inclined L-shaped plate 5212, The guide rod b522 will move downward along the track of the L-shaped plate 5212, thereby driving the hook b523 to move downward while passing through the through hole a515 until the hook b523 enters the through hole e803 of the garbage bag 802, and the first motor 502 continues Rotate, the hook b523 moves forward, but the guide bar b522 has passed the horizontal plate on the L-shaped plate 5212. When the hook b523a was in the through hole e803, the guide bar b522 will break away from the horizontal plate of the L-shaped plate 5212, and the hook b523 continues Moving to the right, the guide bar b522 passes through the horizontal plate of the L-shaped plate 5212. Since there is no hindra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com