Electrical automation equipment

A technology of electrical automation and equipment, applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problems of damaging the quality and safety of cables, affecting the progress of conveying work, and prone to wear and tear, etc., to achieve Achieve protection, promote adsorption, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

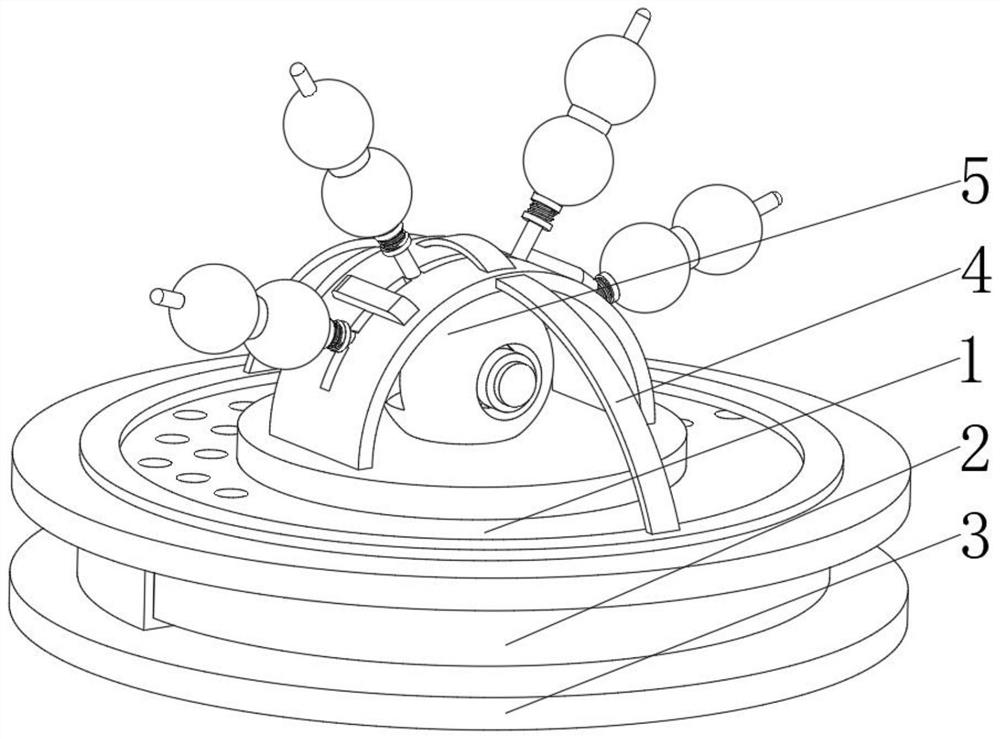

[0037] see Figure 1-3 , the present invention provides a technical solution: an electrical automation equipment, specifically comprising:

[0038] Orbit ring 1, the orbit ring 1 has a ring-shaped rail, and a collection and cleaning mechanism 2 installed at the bottom of the ring-shaped rail, and a base plate 3 fixed at the bottom of the collection and cleaning mechanism 2, and a support frame rod arranged at the top of the ring-shaped rail 4. Through the annular design of the track ring 1 itself, it is convenient to adjust the angle of the components, and there is no need to move and adjust the position after it is installed by itself, which is suitable for the needs of various working environments.

[0039] Lead mechanism 5, this lead mechanism 5 has an antenna body, and the antenna body is installed on the top of the gathering cleaning mechanism 2, and the lead mechanism 5 includes:

[0040]Shaft fixing mechanism 51, the shaft fixing mechanism 51 has a spherical body, and ...

Embodiment 2

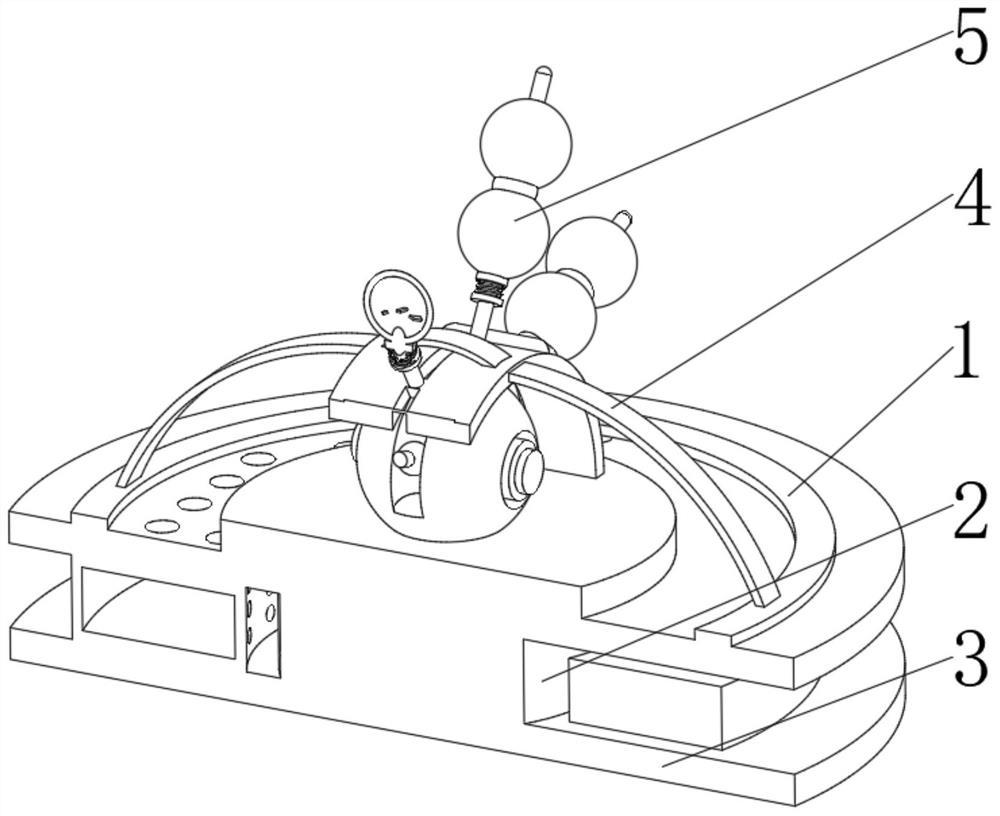

[0044] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: the collection and cleaning mechanism 2 includes an air suction pump 21, and a support plate 22 installed on the top of the air suction pump 21, and the opening on the top side of the support plate 22 The collection hole 23, the filter screen ring 24 installed at the bottom of the support plate 22 and below the collection hole 23, and the cleaning ring rod 25 installed in the inner cavity of the filter screen ring 24. The collection hole 23 is set at the front end of the conveying, and at the same time, the auxiliary airflow is used for suction to remove the dust or magazines left by the cable on the receiver, maintain the friction between the component itself and the cable, and realize the positioning protection of the cable position .

[0045] The filter ring 24 and the cleaning ring rod 25 are located above the base plate 3 , and the bottom of the collecting hole 23 ...

Embodiment 3

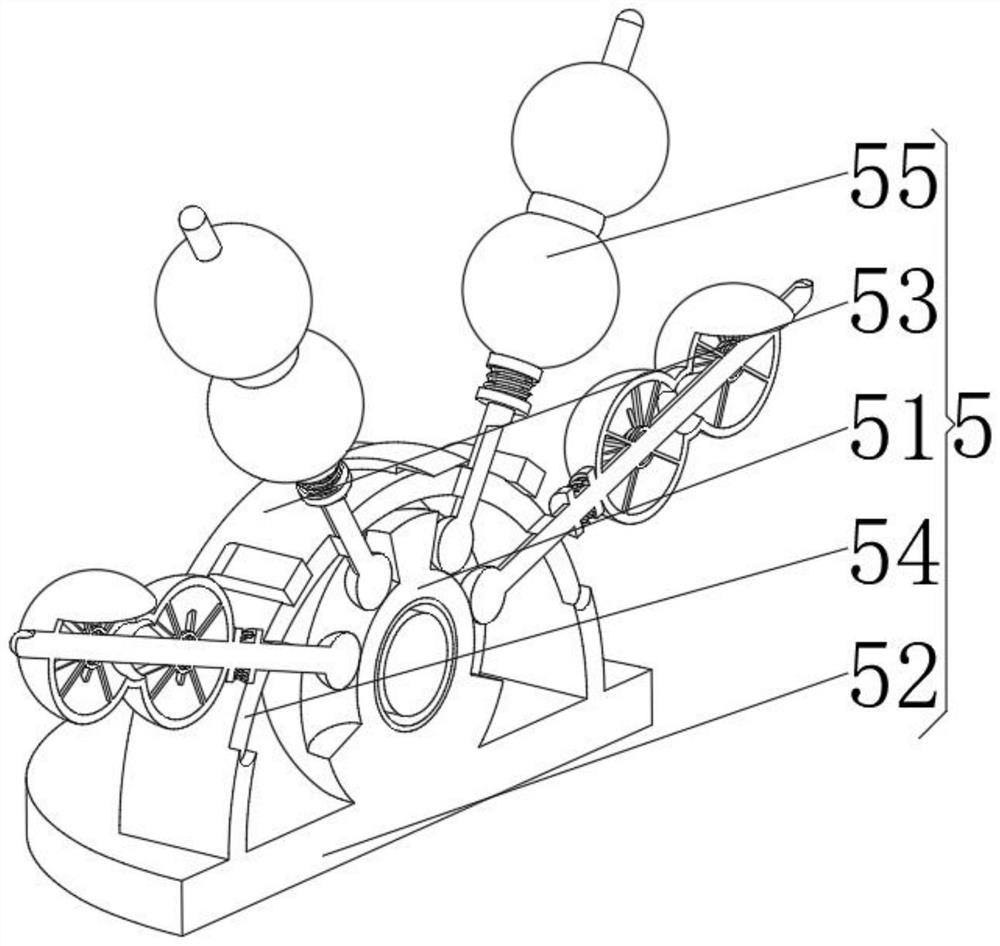

[0048] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the fixed axis mechanism 51 includes a ball seat 511, and a mounting hole 512 opened in the middle of the ball seat 511, and opened outside the ball seat 511 The limiting grooves 513 on both sides of the surface, the mounting balls 514 installed inside the limiting grooves 513 , and the protective sleeve 515 arranged in the inner cavity of the mounting hole 512 . Through the spherical design of the ball seat 511, it is convenient to disperse the impact force on the surface and realize the protection of the whole mechanism. At the same time, the installation equipment of the protective sleeve 515 is convenient for counterweight, which can be changed according to the intensity of transportation, and the overall stability of the mechanism is improved.

[0049] The outer surface of the installation ball 514 is connected to the winding mechanism 55 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com