Self-resetting viscous energy dissipation support based on disc spring

An energy-dissipating support and self-resetting technology, which is applied to building components, building types, and earthquake resistance, can solve problems such as large residual deformation, increase post-earthquake maintenance and reconstruction costs, and achieve good energy consumption and earthquake resistance. Obvious, good self-resetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

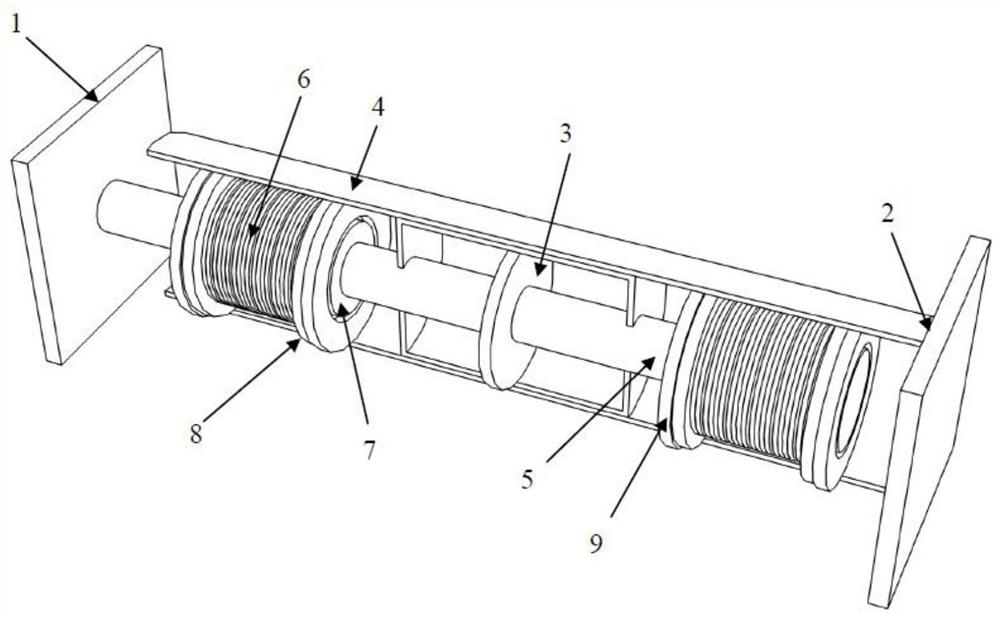

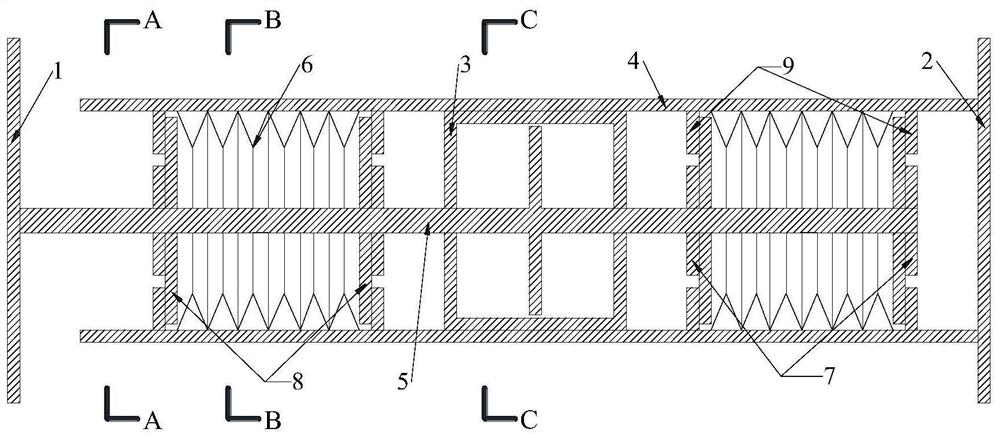

[0034] Such as figure 1 As shown, the disc spring-based self-resetting viscous energy-dissipating support provided in this embodiment is composed of an energy-dissipating component and a self-resetting component.

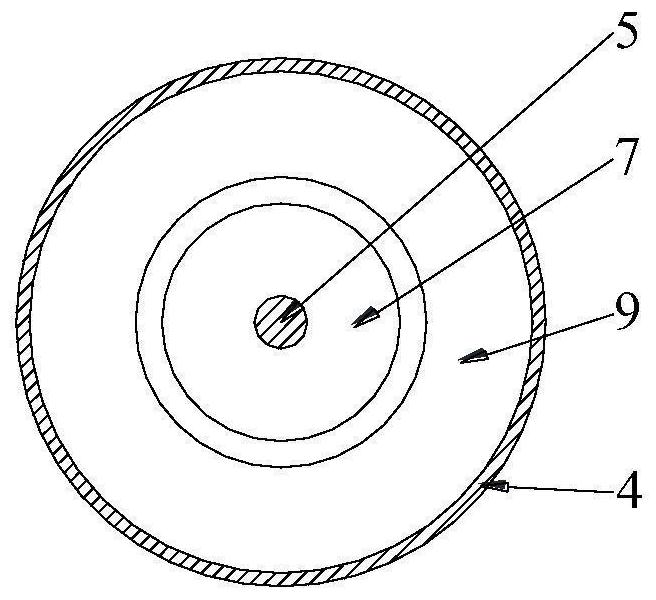

[0035] Energy consumption part: the viscous damper (3) is fixed inside the outer sleeve (4), the inner sleeve (5) is fixed on the left end plate (1), and the outer sleeve (4) is fixed on the right end plate (2) , when the supporting member is under tension or compression, the outer casing (4) and inner casing (5) slide relative to each other, and the viscous damper (3) begins to consume energy.

[0036]Self-resetting part: an inner stopper (7), a baffle plate (8) and an outer stopper (9) are arranged at both ends of the space between the outer casing (4) and the inner casing (5). The inner block (7) is threaded on the inner casing (5), and is fixedly connected with the inner block (5). The outer block (7) is provided with an outer block (9), and the outer block (9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com