Machine-made sand production system

A production system and machine-made sand technology, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of inconvenient sand screening, insufficient sand making, and low sand quality, so as to achieve convenient screening, fine sand making, The effect of fine sand particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

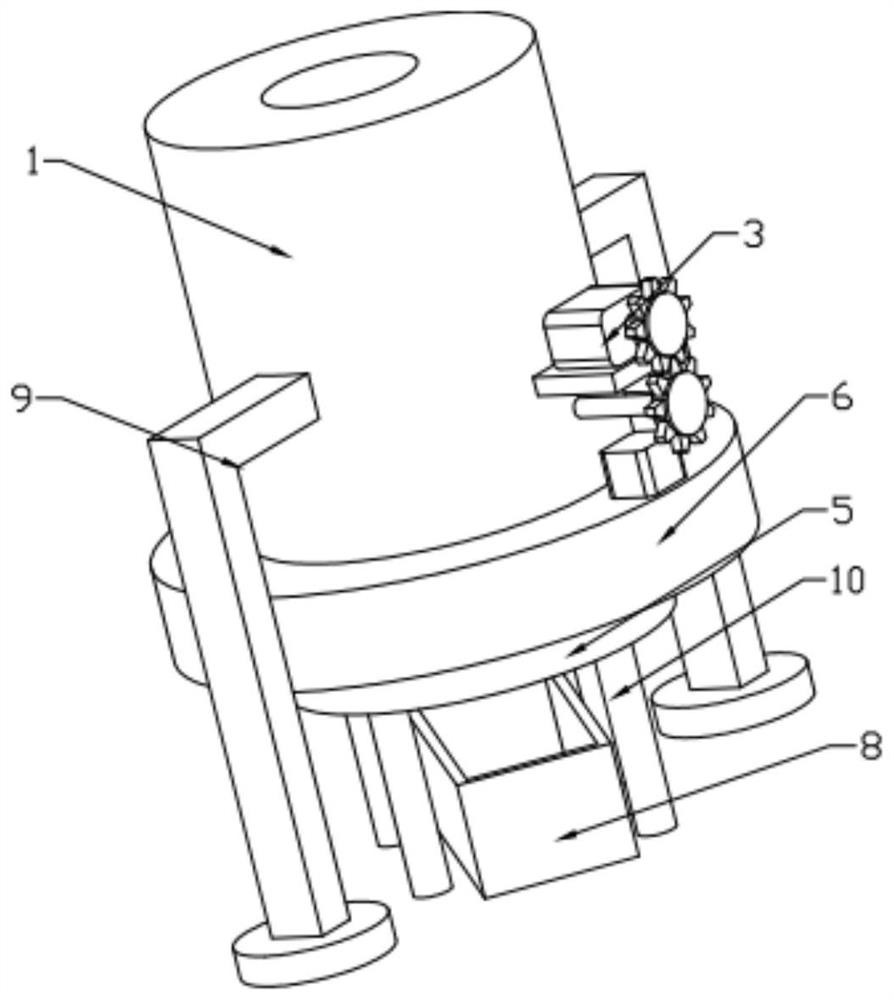

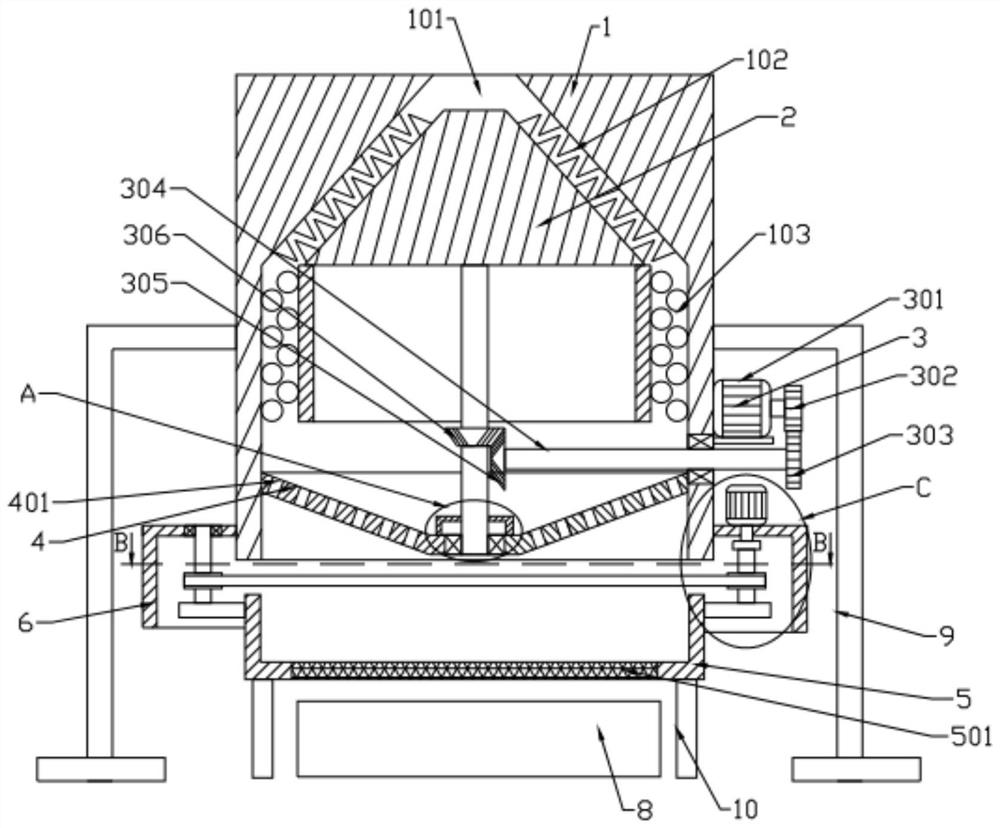

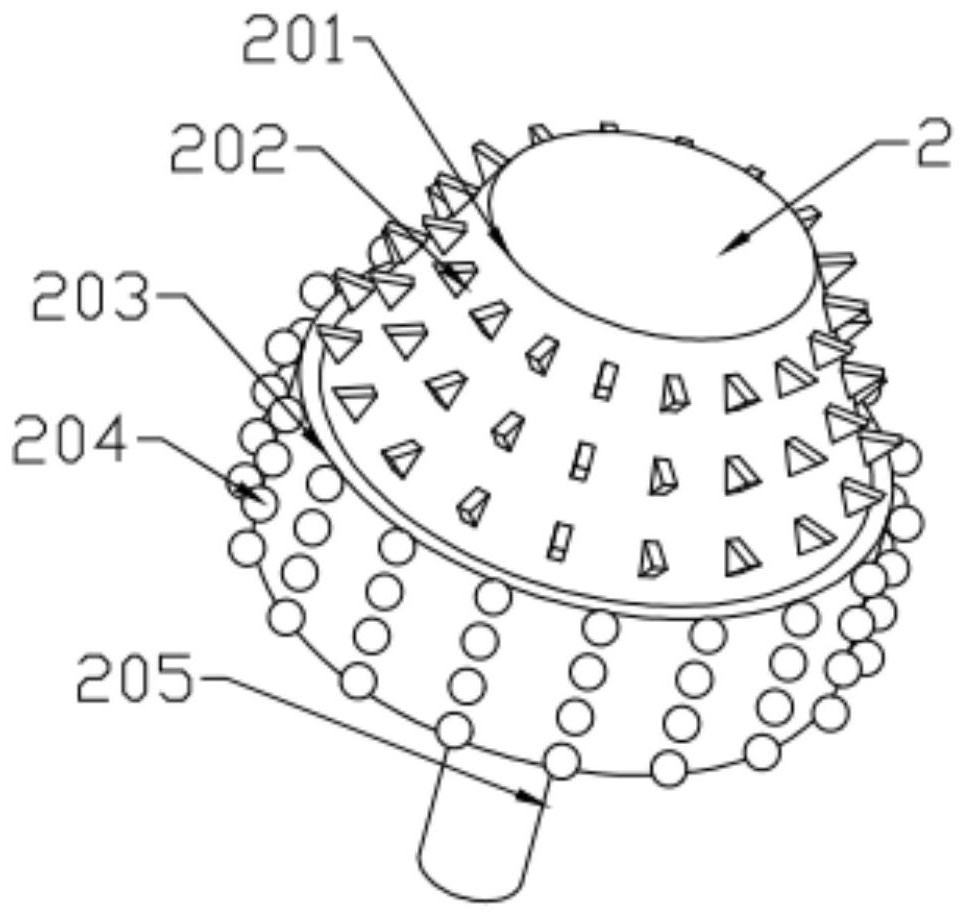

[0026] see Figure 1-6 , in an embodiment of the present invention, a machine-made sand production system includes a sand-making box 1, a cavity 101 is opened in the sand-making box 1, and a blanking plate 4 is installed at the inner bottom of the sand-making box 1, The cross-section of the blanking plate 4 is "V" shaped, and a plurality of blanking holes 401 are evenly distributed on the blanking plate 4, which is conducive to the slipping of the sand material. Sand device 2, the sand making device 2 includes: a round table 201, a first pulverizing blade 202, an annular housing 203, a first grinding ball 204, a rotating shaft 205 and a protective cover 206, and the diameter of the top of the round table 201 is smaller than that of the bottom diameter, a plurality of first crushing blades 202 are uniformly distributed on the outside of the circular platform 201, and a plurality of second crushing blades 102 matched with the first crushing blades 202 are uniformly distributed o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap