Sludge diversion type sewage purification device

A sewage purification and sludge technology, applied in the direction of chemical instruments and methods, filtration separation, fixed filter element filter, etc., can solve the problems of high labor cost, low treatment efficiency, affecting sewage treatment efficiency, etc., and achieve good anti-clogging Performance and mud discharge effect, effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

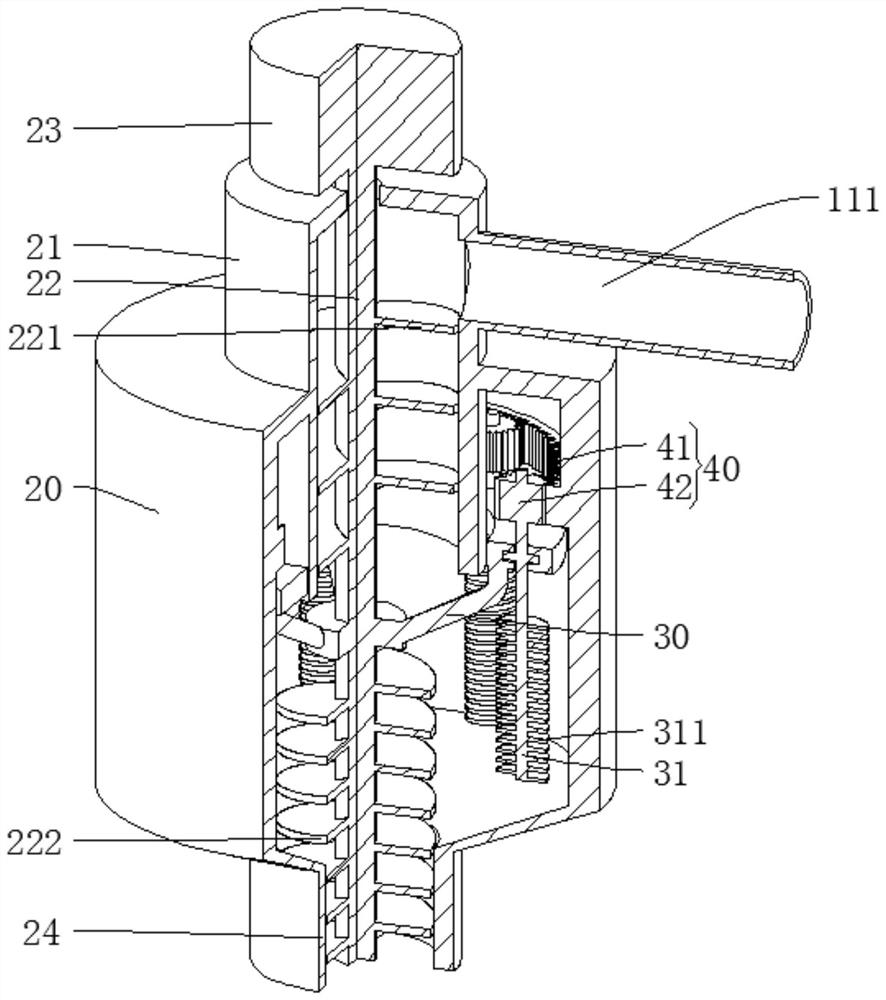

[0032] refer to Figure 1 to Figure 6 , the invention provides a sludge diversion type sewage purification device, comprising:

[0033] Sewage pipe 10, sleeve pipe 11 is set on the sewage pipe 10, several grille openings 12 are provided at the position where the sewage pipe 10 is socketed by the sleeve pipe 11, and the sewage pipe 10 is provided with a The slag discharge mechanism 13, the casing 11 is provided with a water outlet pipe 11;

[0034] The cylinder 20 is provided with a central pipe 21, a central rod 22, a driving device 23 and a drain pipe 24. The central pipe 21 communicates with the outlet pipe 11, and the central rod 22 is rotatably mounted on the cylinder 20. The central pipe 21 is connected to the The central rod 22 is coaxially arranged, and the central rod 22 is provided with a first helical blade 221 matched with the central pipe 21 and a second helical blade 222 matched with the drain pipe 24, and the driving device 23 is connected with the central rod 2...

Embodiment 2

[0043] refer to Figure 1 to Figure 6 , in combination with the technical solution of Embodiment 1, in this embodiment, the transmission mechanism 40 includes an inner ring gear 41 and several planetary gears 42, the inner ring gear 41 is arranged on the cylinder 20, and the planetary gears 42 are arranged on the rotating rod 31, The planetary gears 42 mesh with the ring gear 41 .

[0044] When the driving device 23 drives the central rod 22 to drive the turret 30 to rotate, several rotating rods 31 on the turret 30 will revolve. When the rotating rods 31 are working, the planetary gear 42 on the rotating rod 31 will function as the inner ring gear 41 Rotate downwards to realize the simultaneous rotation and revolution of the rotating rod 31, so as to improve the disturbance effect of the third helical blade 311 on the rotating rod 31 on the sewage, play a role in refining the sludge particles, and improve the fluidity of the sewage , wherein the rotation direction of the rot...

Embodiment 3

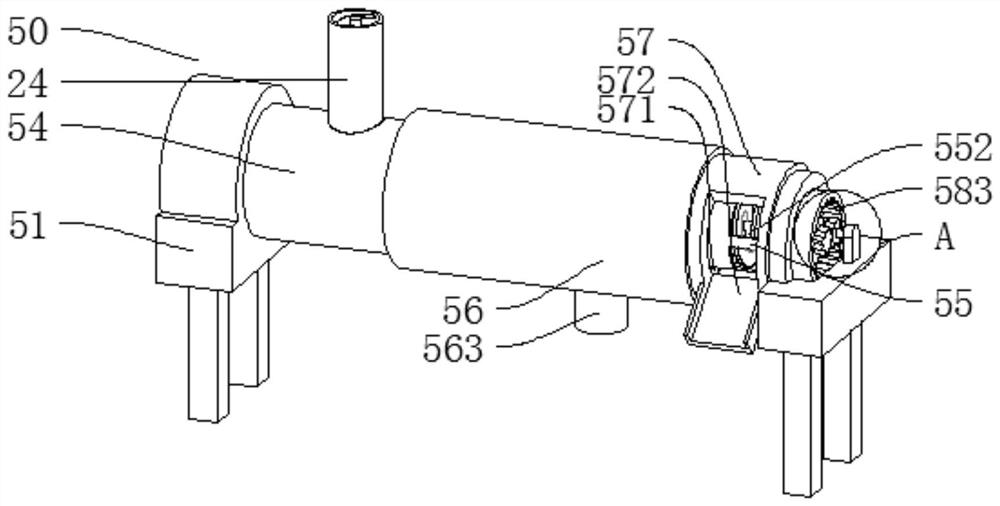

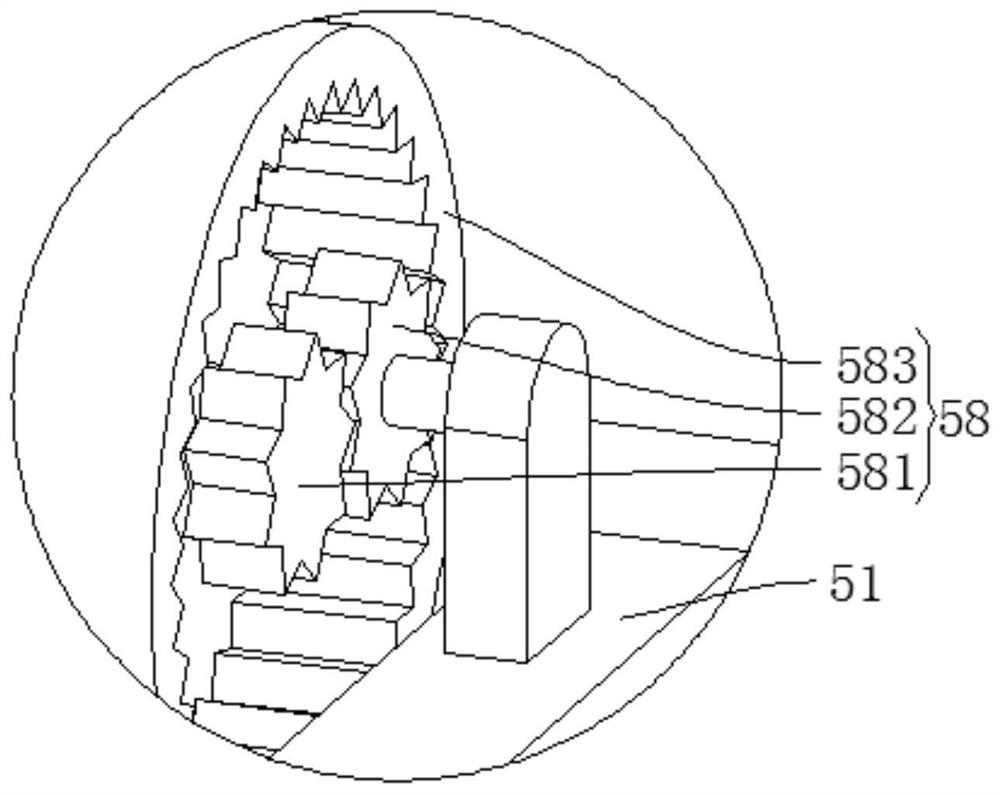

[0047] refer to Figure 1 to Figure 6 , in combination with the technical solutions of Embodiment 1 and Embodiment 2, in this embodiment, the mud discharge mechanism 50 includes a frame body 51 and a second drive motor 52 arranged on the frame body 51, a rotating shaft 53 with helical blades, a main body 54. Rotating cylinder 55, water purification cylinder 56, sludge sleeve 57 and transmission assembly 58, the main body 54 communicates with the drain pipe 24 and the rotating cylinder 55 respectively, the rotating cylinder 55 is installed on the frame body 51 in rotation, and the rotating shaft 53 is connected with the rotating cylinder The cylinder 55 is coaxially arranged and rotatably mounted on the cylinder 55. The second driving motor 52 is connected to the rotating shaft 53 and can drive the rotating shaft 53 to rotate. The transmission assembly 58 can transmit the power at the rotating shaft 53 to the rotating cylinder 55 and drive the rotation The drum 55 rotates, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com