Anti-corrosion sealing method for internal cavity of covering cap

An internal cavity, anti-corrosion technology, used in aircraft accessories and other directions, can solve the problems of difficulty in maintaining sealing, easy accumulation of corrosive liquids, corrosion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

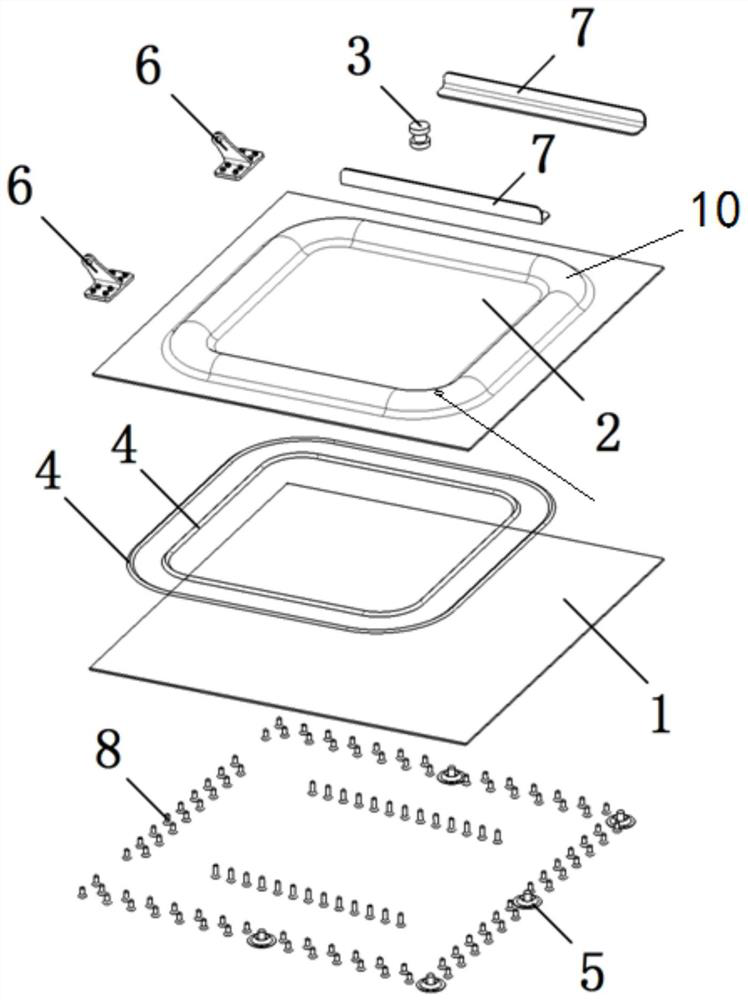

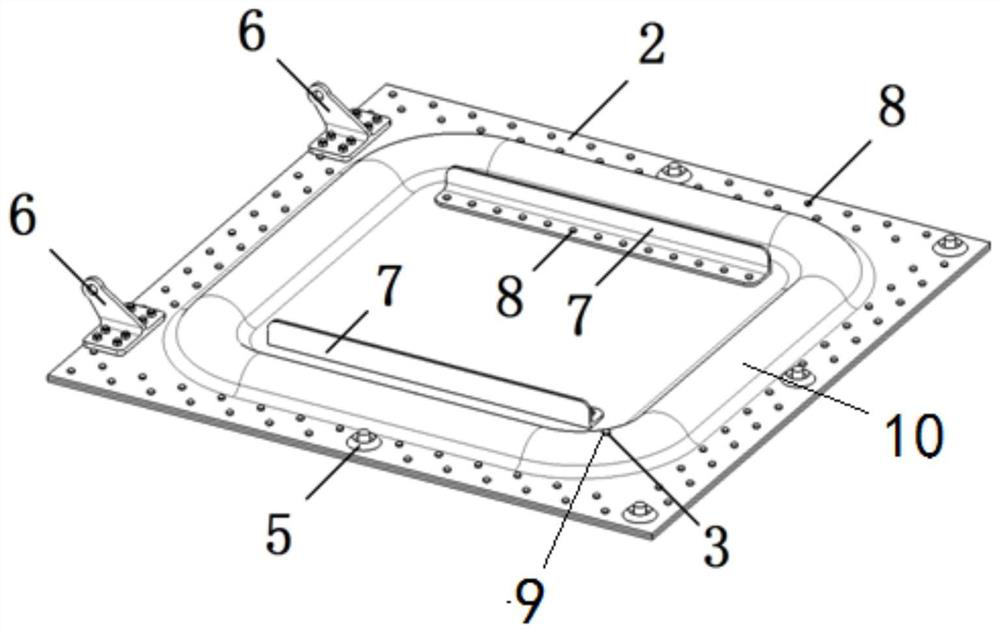

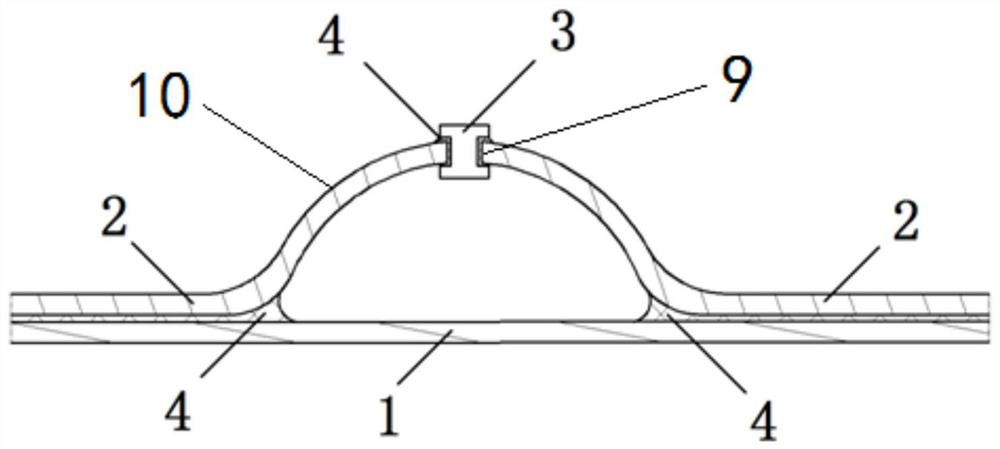

[0013] Referring to the accompanying drawings, an anti-corrosion sealing method for the inside of a cover of the present application includes an outer skin 1, an inner skin 2, a blind rivet 3, a sealant 4, a quick-release lock 5, a rotating bracket 6, a reinforced profile 7, an ordinary Rivet 8.

[0014] In practice, the inner skin 2 is provided with a ring-shaped reinforcing dimple 10 , and the outer skin 1 and the inner skin 2 are fixedly connected by rivets 8 on the outside of the ring-shaped reinforcing dimple 10 to form an integral structure of the cover body. In order to seal the inner cavity of the reinforcement nest and prevent rainwater from pouring into the corroded opening cover structure, the application provides a glue filling hole 9 on the top of the reinforcement nest 10 of the inner skin 2; inject liquid sealant into the reinforcement nest 10 through the glue filling hole 9; After injecting the liquid sealant, turn the posture of the cover body so that the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com