Cable winding device for ocean engineering

A winding device and marine engineering technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve problems such as easy unraveling, weak cables, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

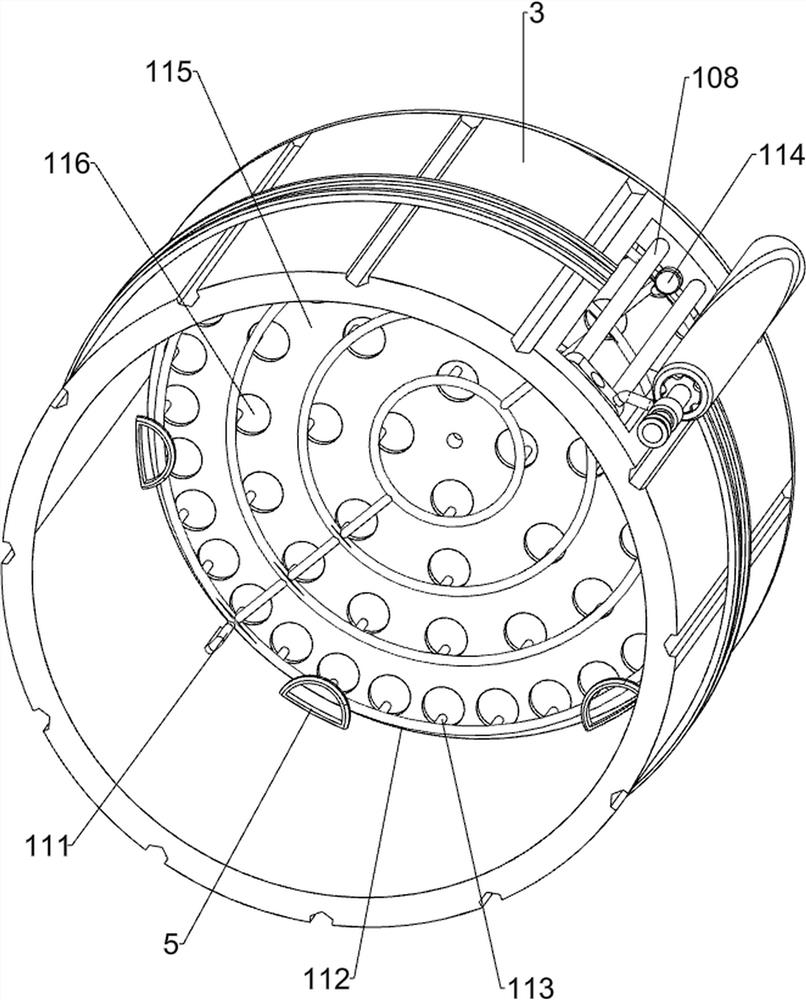

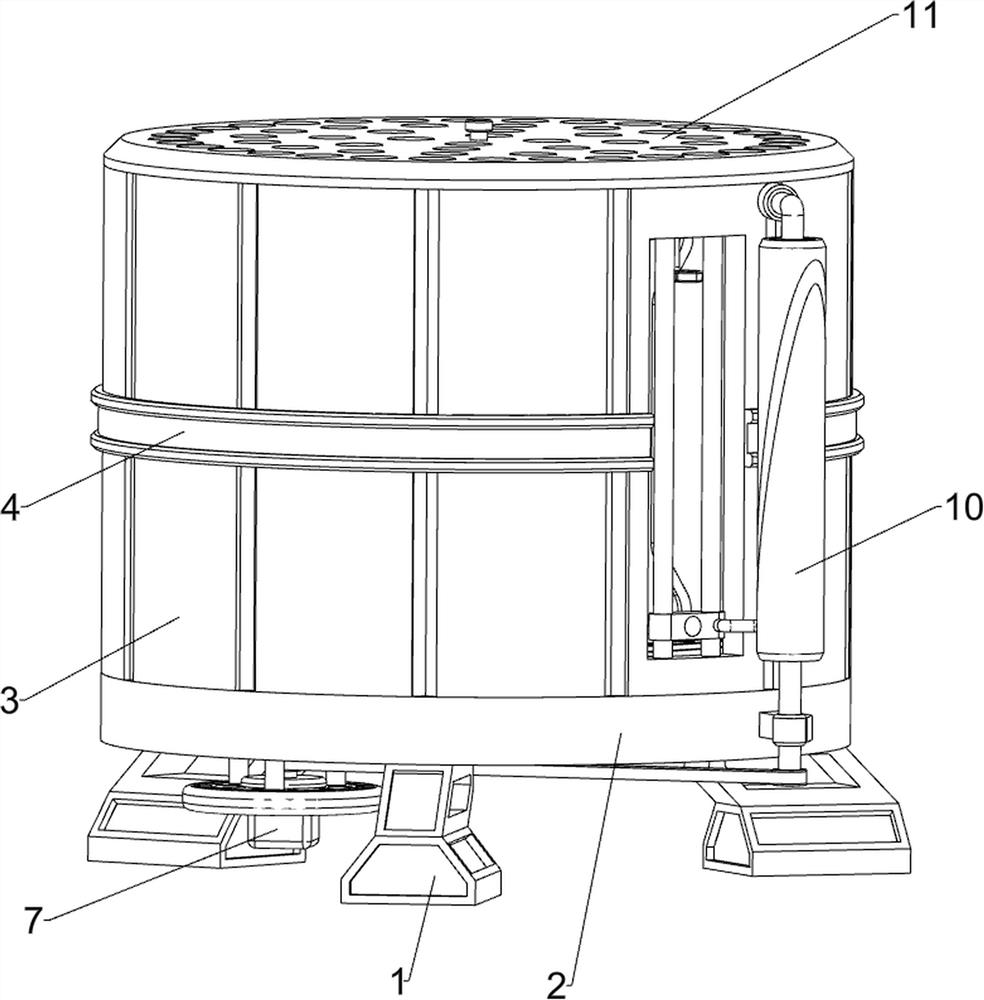

[0025] A cable winding device for marine engineering, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 As shown, it includes a mounting frame 1, a collecting tray 2, a guardrail 3, a fixing ring 4, a support block 5, a winding mechanism 6 and a driving mechanism 7, and three mounting frames 1 are evenly arranged at the bottom of the collecting tray 2, and the top of the collecting tray 2 A guardrail 3 is provided, a fixed ring 4 is provided in the middle of the guardrail 3, six support blocks 5 are equidistantly arranged on the upper part of the inner wall of the guardrail 3, and a rewinding mechanism 6 is provided on the collecting tray 2, and the rewinding mechanism 6 and the collecting tray 2 A driving mechanism 7 is connected therebetween.

[0026] The winding mechanism 6 includes a storage frame 61, a first rotating rod 62, a winding rod 63, and an installation buckle 64. The storage frame 61 is arranged in the middle of the top of the collecting tray...

Embodiment 2

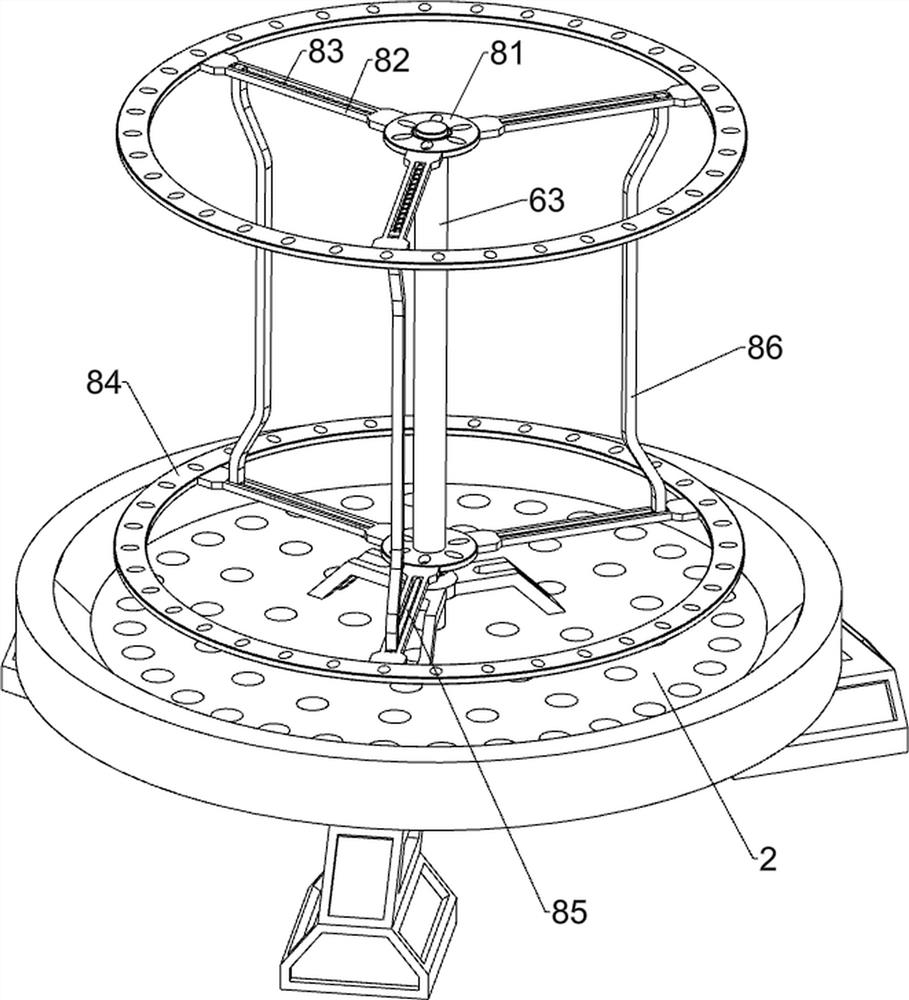

[0030] On the basis of Example 1, such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, it also includes a retractable mechanism 8, which includes a retractable disc 81, a connecting plate 82, a screw rod 83, a leakage plate 84, a guide rod 85 and a retractable plate 86, and the outer side of the retractable rod 63 is symmetrically rotated up and down. A retractable tray 81 is provided, and three connection plates 82 are arranged on the outside of the retractable tray 81, and leaking plates 84 are connected between the upper connection plates 82 and the lower connection plates 82, and the lower connection plates 82 are provided with Guide rod 85 is arranged, and on the guide rod 85, the sliding type is provided with retractable plate 86, and in the upper side connecting plate 82, the screw rod 83 is rotated, and screw rod 83 is threadedly connected with the retractable plate 86 on the same side.

[0031] The staff can first adjust the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com