Single-hand ratchet wheel open spanner

An open-end wrench and ratchet technology, applied in the directions of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of inconvenient adjustment and difficulty for people with pipe wrenches to easily access the pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

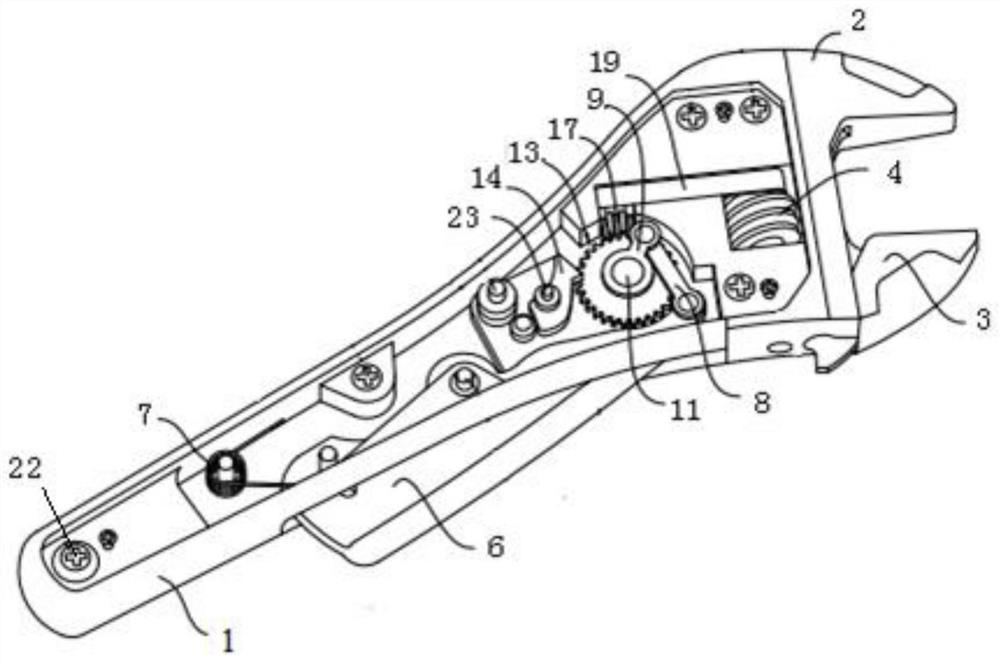

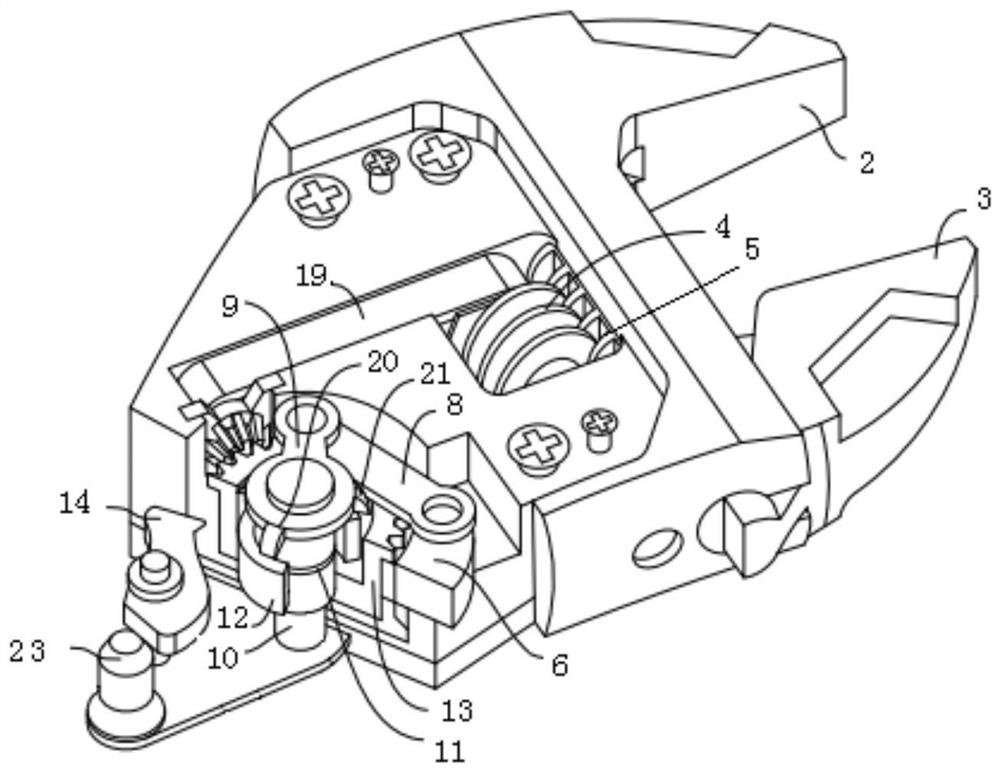

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

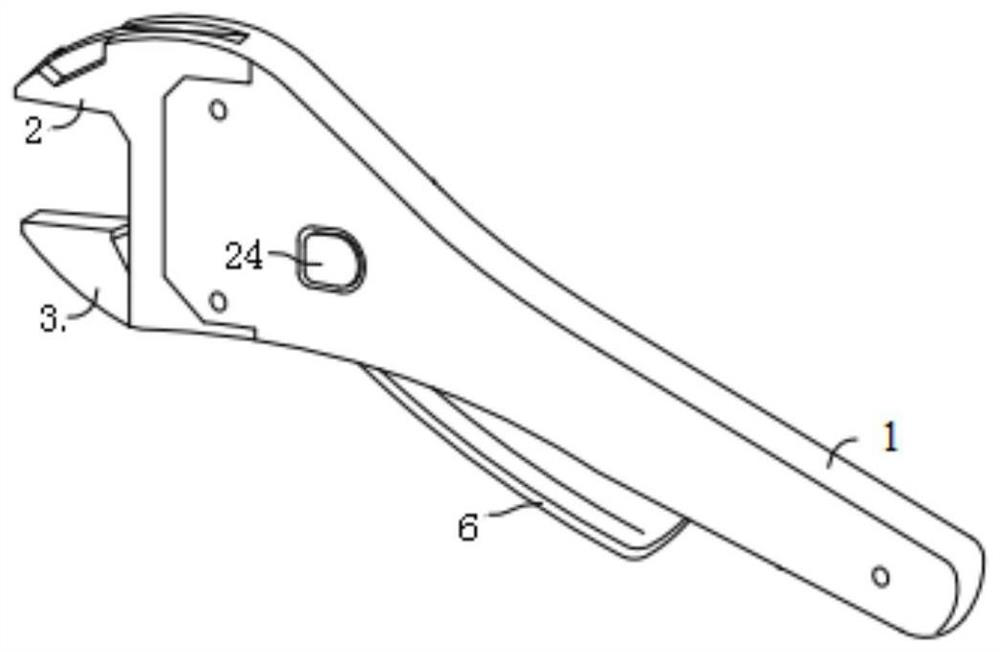

[0018] like Figure 1-4 As shown, a single-handed ratchet open-end wrench includes a pliers handle 1 on which a fixed jaw block 2, a movable jaw block 3, and an adjusting worm that drives the movable jaw block 3 to move toward the fixed jaw block 2 4. The movable jaw block 3 is provided with teeth 5 matching with the adjusting worm 4 .

[0019] An adjustment handle 6 is hinged on the clamp handle 1, and a side return spring 7 that pushes out the adjustment handle 6 after the inward rotation is provided on the clamp handle 1. A drive rod 8 is hinged on the adjustment handle 6, and the end of the drive rod 8 is hinged with a Connecting rod 9, clamp handle 1 is provided with upper return spring 10, and upper return spring 10 is connected with central rod 11, and central rod 11 is provided with clutch 12, and the outer surface of clutch 12 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com