Laminating machine with automatic glue-pressing function

A laminating machine, automatic technology, applied in container manufacturing machinery, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc., can solve the problems of inability to automatically glue, low production efficiency, etc., to achieve safe and convenient use, guarantee Smoothness, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

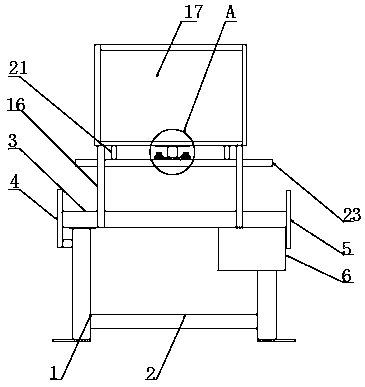

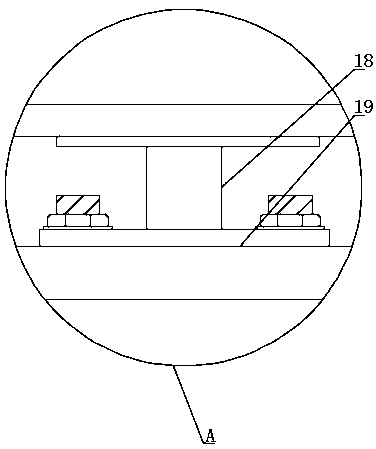

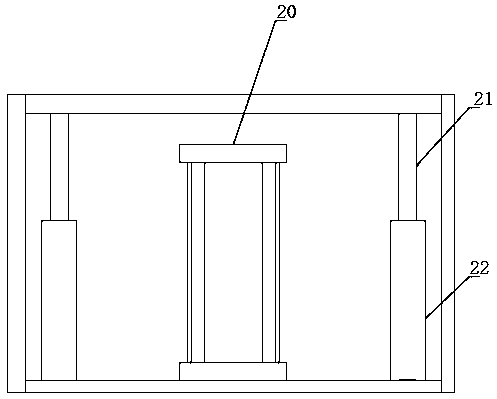

[0020] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a laminating machine for automatic gluing, including a bracket 1. In order to facilitate fixing the laminating machine, a backing plate is installed at the bottom of the support 1, and bolt holes are provided at the four corners of the backing plate. 1 are connected to each other by a cross bar 2. A protective frame 3 is installed on the top of the bracket 1. A front baffle 4 is installed on one end of the protective frame 3. In order to prevent the carton from slipping, the front baffle 4 is concave in shape, and the other end of the protective frame 3 is installed Rear baffle 5, in order to move front baffle 4 and rear baffle 5 conveniently, front baffle 4 and rear baffle 5 are all connected with support 1 through slide block and guide rail, gear box 6 is installed in the middle part of protective frame 3, and gear box 6 The back side is connected with a motor 7, in order to fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com