Double-torsion-shaft type pressing device

A compression device and double torsion technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of pressing and loosening troubles, installation and disassembly time-wasting, etc., to achieve convenient control and operation, simple and compact structure, compression strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

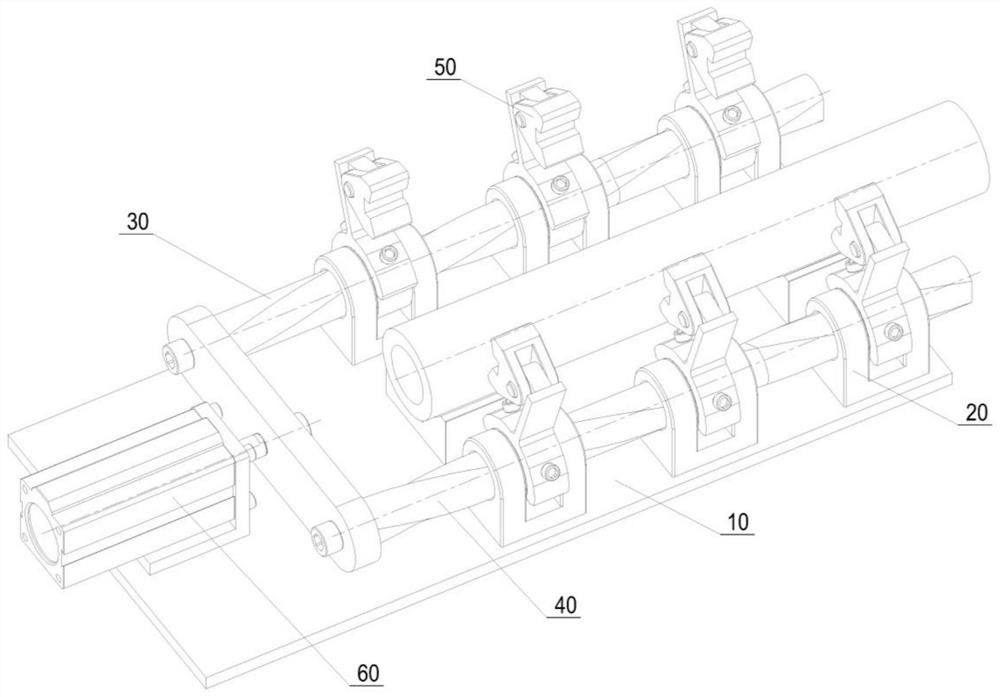

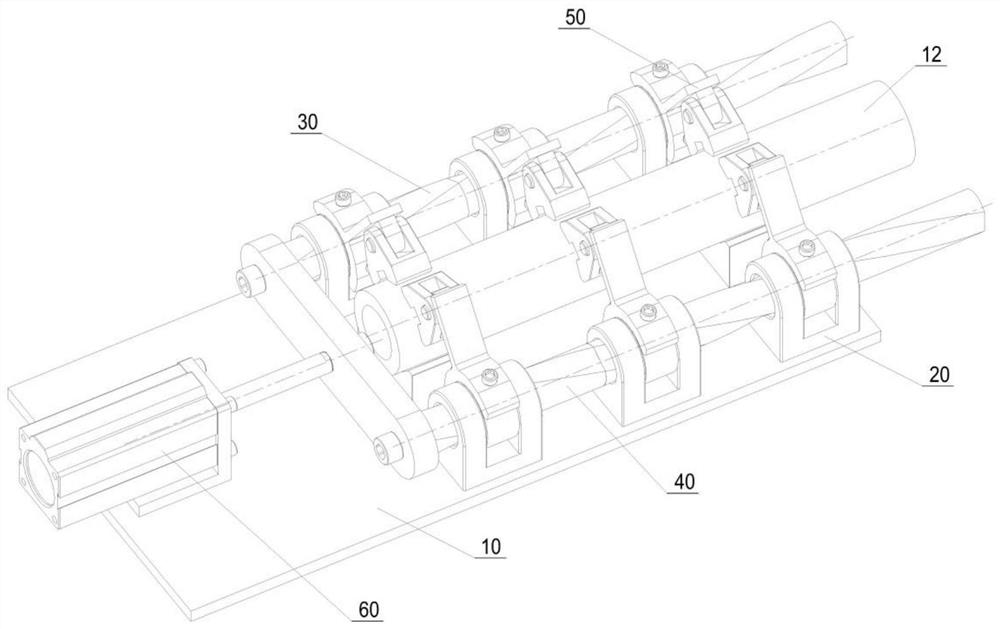

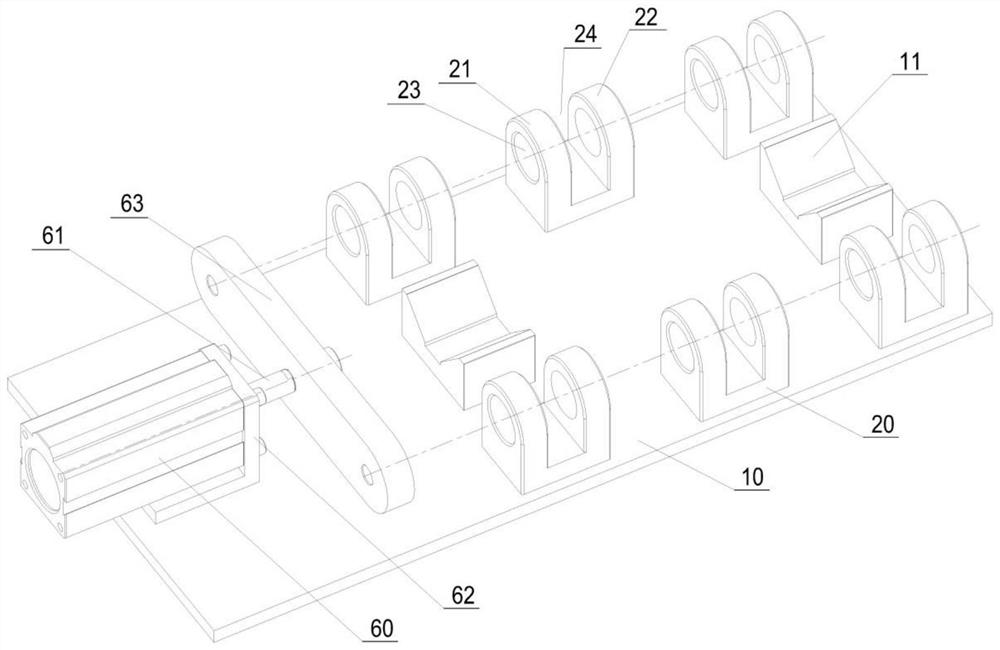

[0021] like Figure 1 - Figure 4 As shown, a double twisted axis pressing device is disclosed, including:

[0022] The substrate 10, the substrate 10, and the sides are provided with a plurality of grouping seats 20, and the guiding seat is provided with a light pond hole 23 and a guide groove 24; there is a V shape for placing a workpiece between the sides of the guide 20. Block 11; rectangular substrate 10 level setting;

[0023] Torsional multilateral shaft assembly 40, the torsional polygonal assembly includes a torsional multilateral shaft and a sliding sleeve, and the slider is connected to a rod assembly 50; the torsional multilateral shaft is provided in the light hole 23, the slide jacket and the torsional multilateral The shaft sleeve is connected to the guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com