Portable automatic equipment maintenance platform

An automation equipment and maintenance platform technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems of inconvenient placement of precision parts and tools, inconvenient storage and portability, inconvenient use, etc., to achieve easy portability, increased convenience, and easy storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

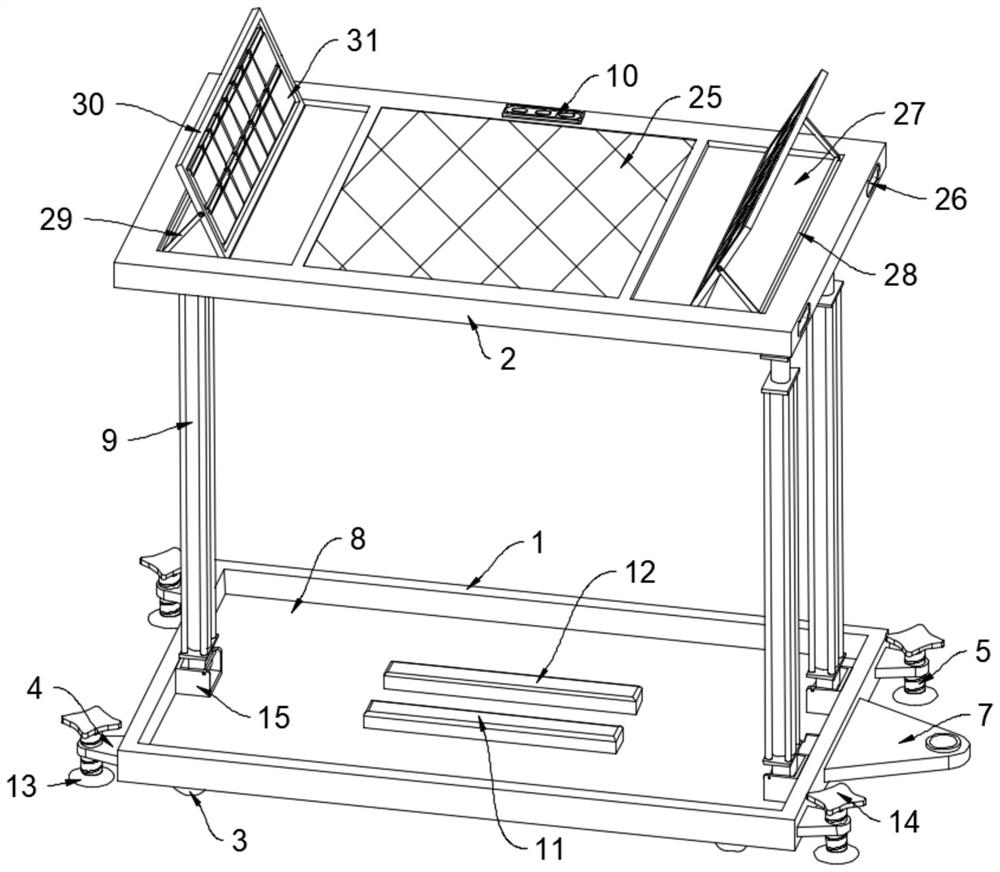

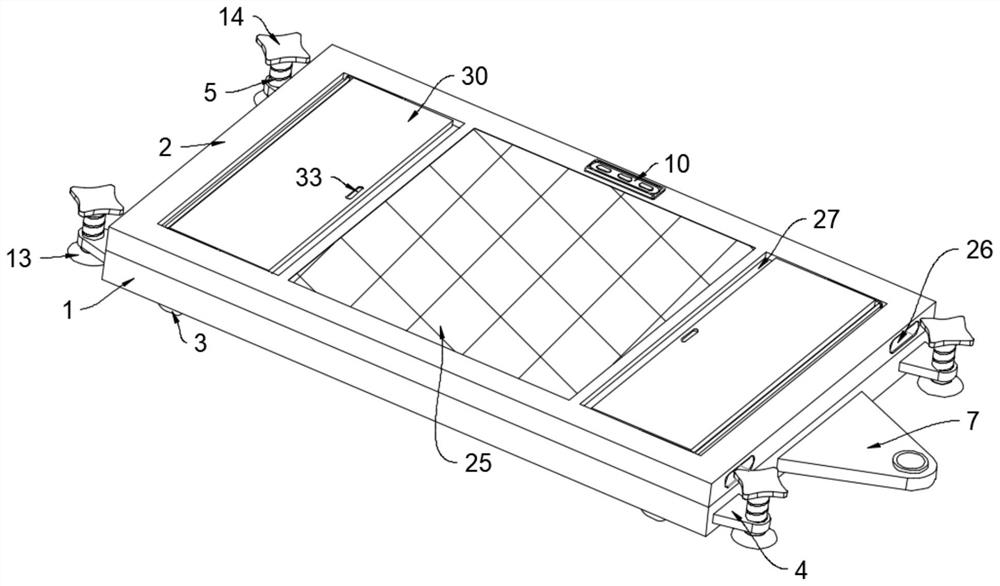

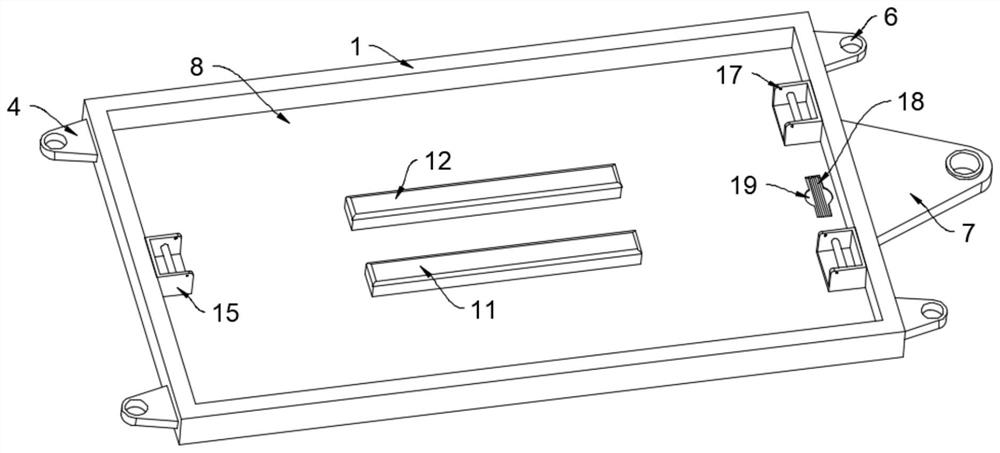

[0036] Embodiment 1, when the present invention is in use, the control panel 10 is used to control the rotation of the road wheels 3 or to pull the traction plate 7 to move the present invention, so that the present invention moves to a suitable position, which is convenient for carrying the present invention, and when moving After reaching the proper position, turn the support rod 5 by turning the handle 14, so that the foot pad 13 is in contact with the ground, avoid the movement of the base plate 1, and improve the stability of the base plate 1, lift the lifting platform 2 by the slot 26, and when lifted When lifting the platform 2, due to gravity, the slider 22 moves downward from the inside of the engaging groove 24, and moves to the inside of the chute 23, and continues to lift the lifting platform 2, so that the slider 22 is on the inside of the chute 23. Slide inside, and make the cylinder 9 tend to rotate along the fixed seat 15 in the vertical direction. When the cyli...

Embodiment 2

[0038] Embodiment 2, when the present invention is being stored and carried, the tool board 30 is pulled through the pull groove 33, so that the tool board 30 is rotated, so that the tool board 30 is parallel to the lifting platform 2, and the tool board 30 is lowered by rotating the support plate 29. To the inside of the concave groove 27, and make the canvas bag 31 contact with the lower surface of the concave groove 27, it is convenient to store the tool plate 30, and it is convenient to cover the canvas bag 31, and it is convenient to store tools and parts. The plate 10 closes the cylinder 9, so that the cylinder 9 drops to the lowest state, and the personnel get off the lifting platform 2, and pull the pin rod 18 from the inside of the pin hole 17, and place it in the inside of the placement groove 19, so as to facilitate alignment of the pin rod 18. storage, and through the groove 26, the lifting platform 2 is lifted, so that the slider 22 is separated from the snap-in gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com