Method and system for forecasting C warping in hot galvanizing continuous annealing process

A hot-dip galvanizing and continuous annealing technology, applied in geometric CAD, special data processing applications, instruments, etc., can solve the problems of not providing control technology and methods in terms of mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

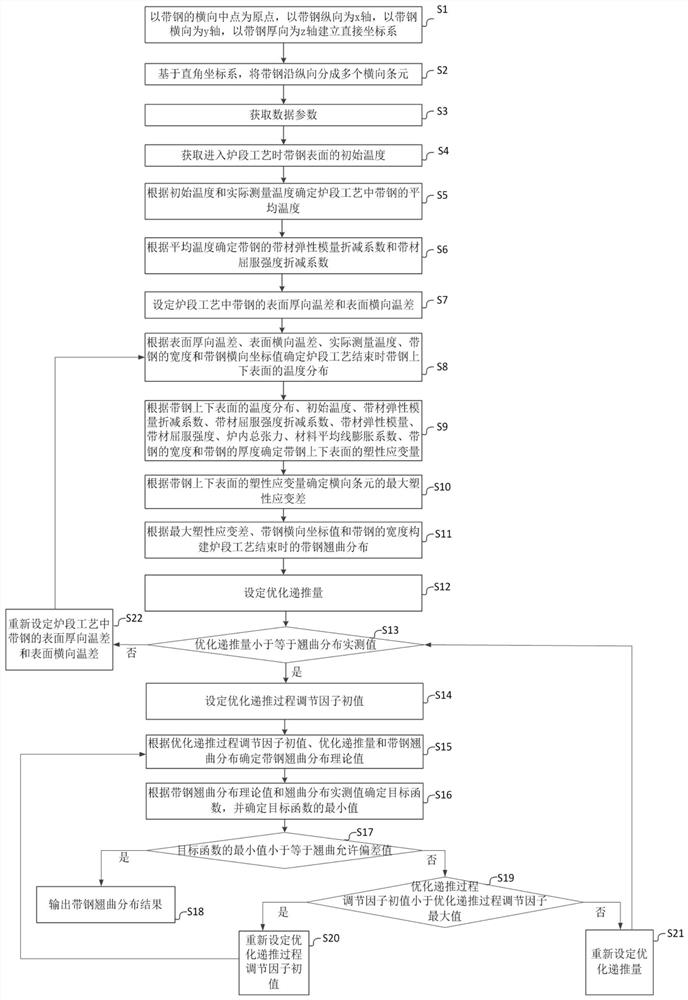

Method used

Image

Examples

Embodiment 1

[0141] Taking the steel strip specification as 900mm×0.5mm, the C-seeker shape is predicted in the heating section of the continuous annealing process. Firstly, in step A, the strip specifications, process parameters of the soaking section, plate shape parameters at the exit of the unit, optimization process parameters, and the maximum value of the adjustment factor λ in the optimization recursive process are collected max and the maximum value of optimal recursion Δw max . The specifications of the collected strip include width B and thickness H. The process parameters of the soaking section include the set temperature T of the strip surface in this section s , Measured temperature T m , the total tension F in the furnace. The profile parameters of the unit outlet include the measured value of the warping distribution of the unit outlet profile w gm , the allowable deviation value ψ of warpage required by the product outline * . The optimized process parameters include...

Embodiment 2

[0168] Taking the steel strip size as 1000mm×1mm, the C-seeker shape prediction of the soaking section in the continuous annealing process is carried out. Firstly, in step A, the strip specifications, process parameters of the soaking section, plate shape parameters at the exit of the unit, optimization process parameters, and the maximum value of the adjustment factor λ in the optimization recursive process are collected max and the maximum value of optimal recursion Δw max . The specifications of the collected strip include width B and thickness H. The process parameters of the soaking section include the set temperature T of the strip surface in this section s , Measured temperature T m , the total tension F in the furnace. The profile parameters of the unit outlet include the measured value of the warping distribution of the unit outlet profile w gm , the allowable deviation value ψ of warpage required by the product outline * . The optimized process parameters incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com