Integral optimization technology of circulating cooling water system

A circulating cooling water, overall optimization technology, applied in the industrial field, can solve the problems of increasing system water supply pressure and flow, high system energy consumption, energy waste, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

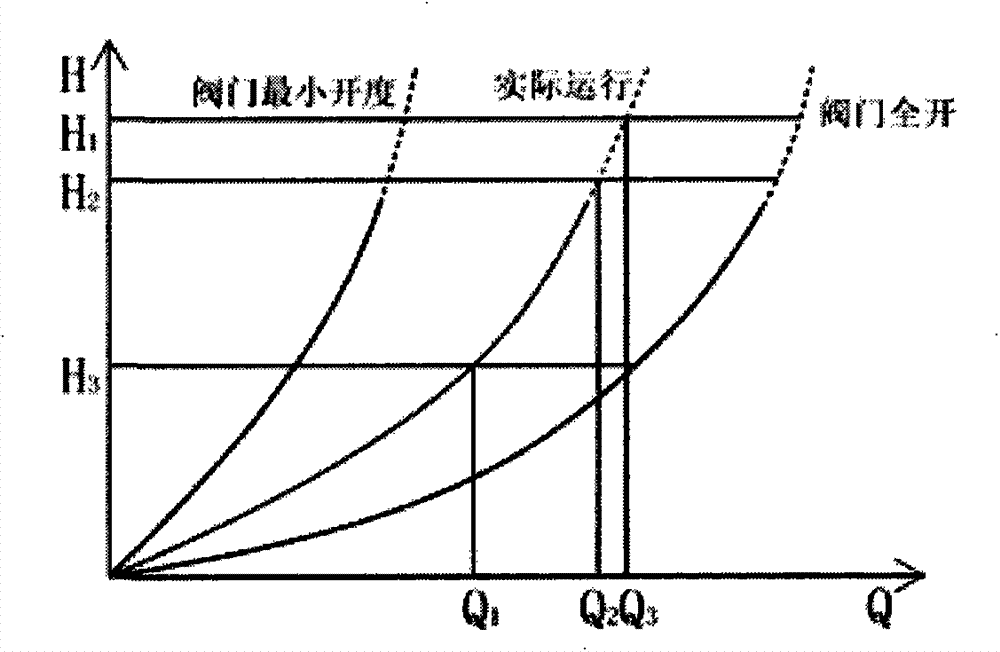

[0029] figure 1 It is the situation that the system runs for one overhaul period, and the curve is the minimum water pump head required by the system with the change of time and ambient temperature. h 3 It is the maximum value of the minimum head of the water pump required by the system during an overhaul period. Theoretically, the design head of the water pump only needs to be greater than H 3 That is, causing wasteful energy consumption of the system. However, the designer lacks the basis for design calculation and cannot find out H 3 , can only continue to use the past design results, and even increase the H 1 , resulting in a larger system margin.

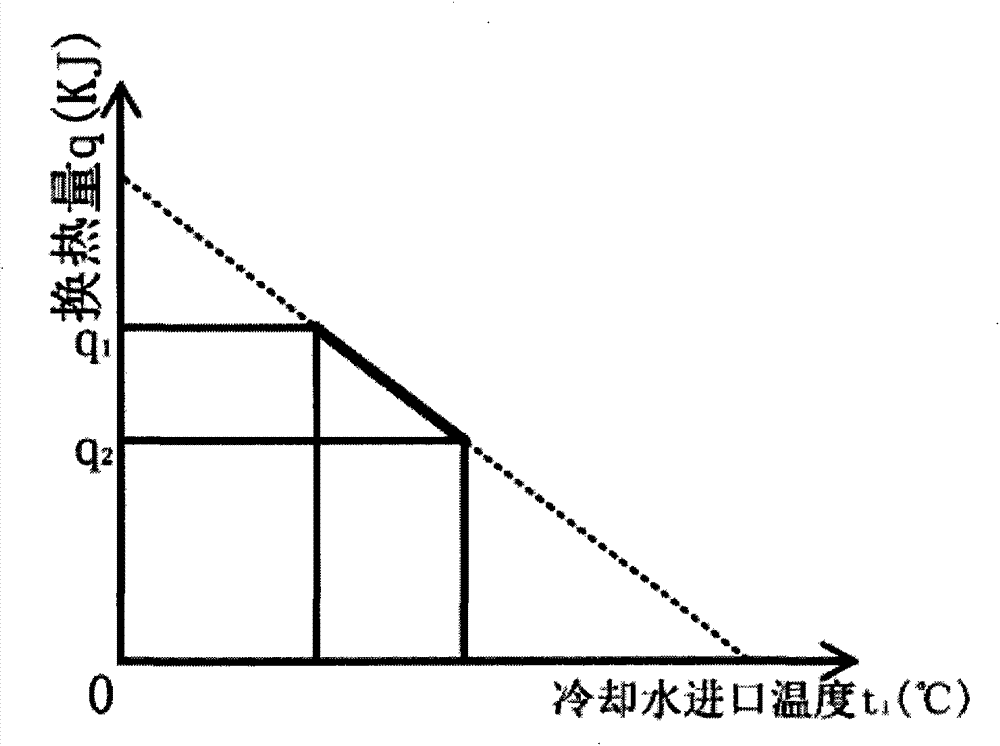

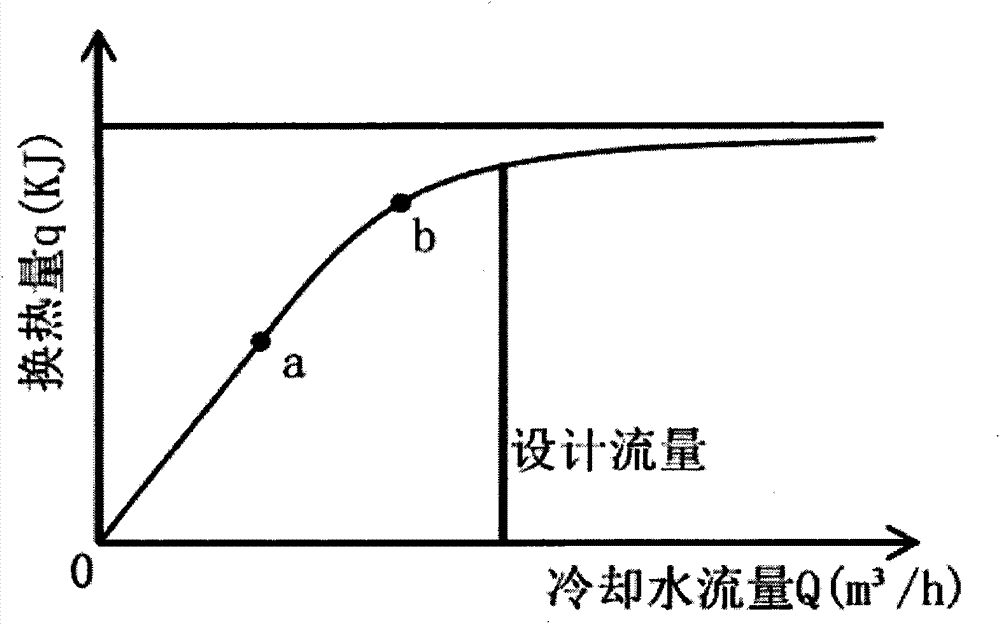

[0030] Through specific calculation and analysis of the operating conditions of each heat exchanger, the water demand under the limit conditions of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com