Electronic control unit for a heating device

A technology for electronic control equipment and heating devices, which is applied in seat heating/ventilation devices, electric heating devices, electrical components, etc., can solve the problems of increased assembly cost, increased system complexity, and increased number of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

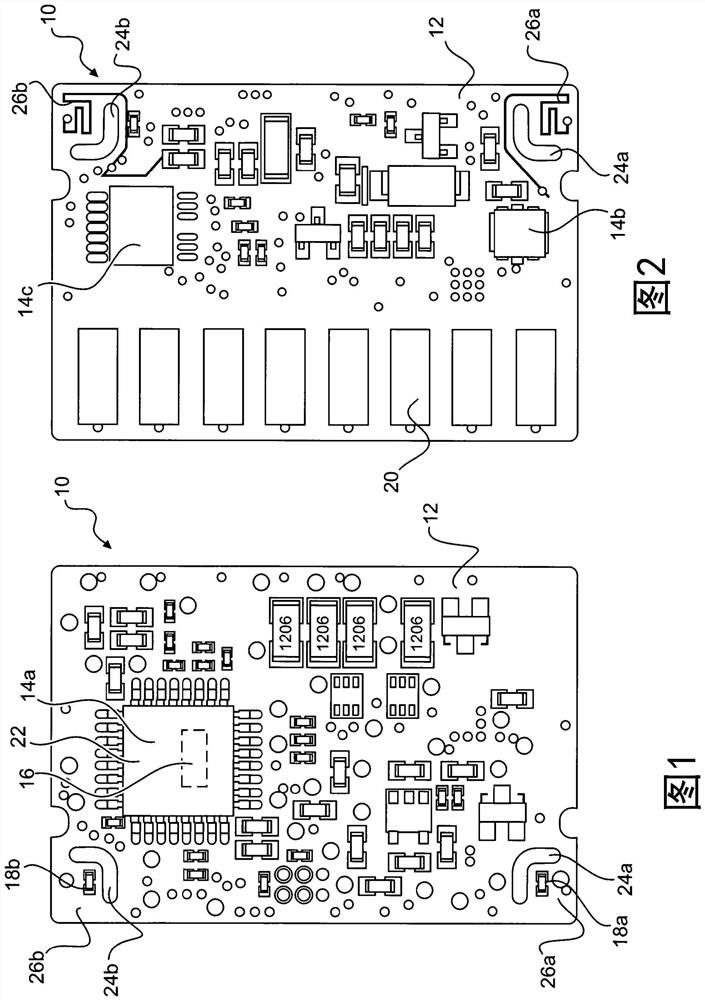

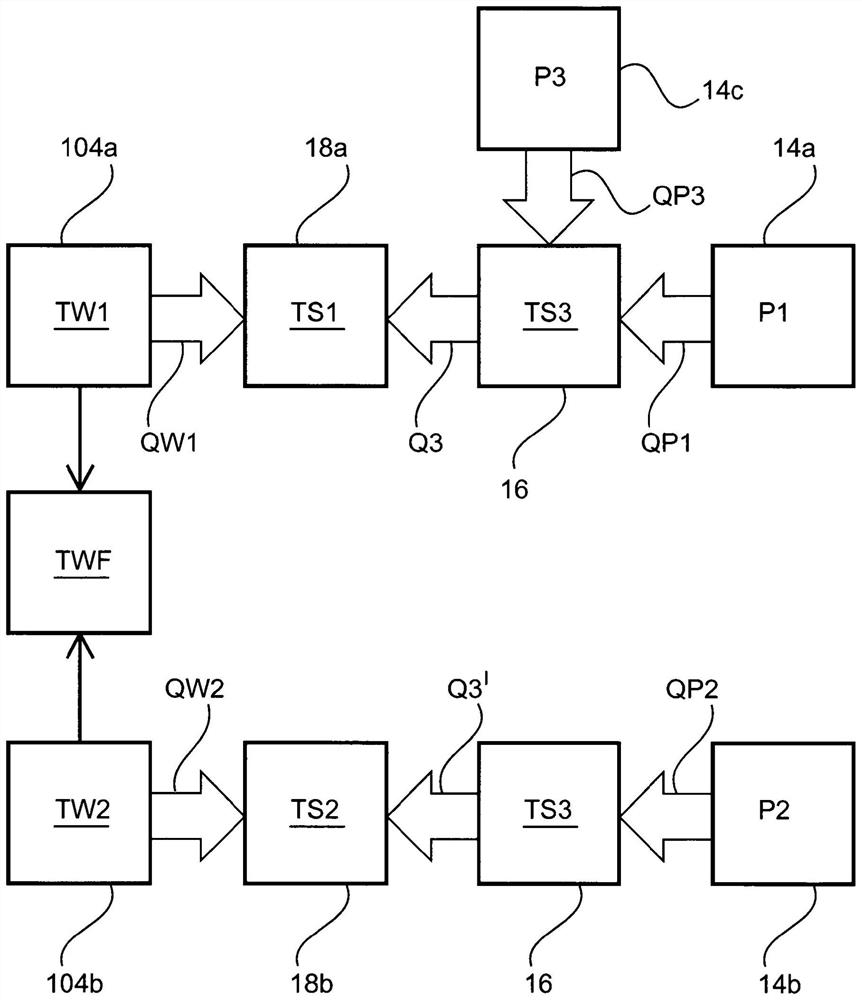

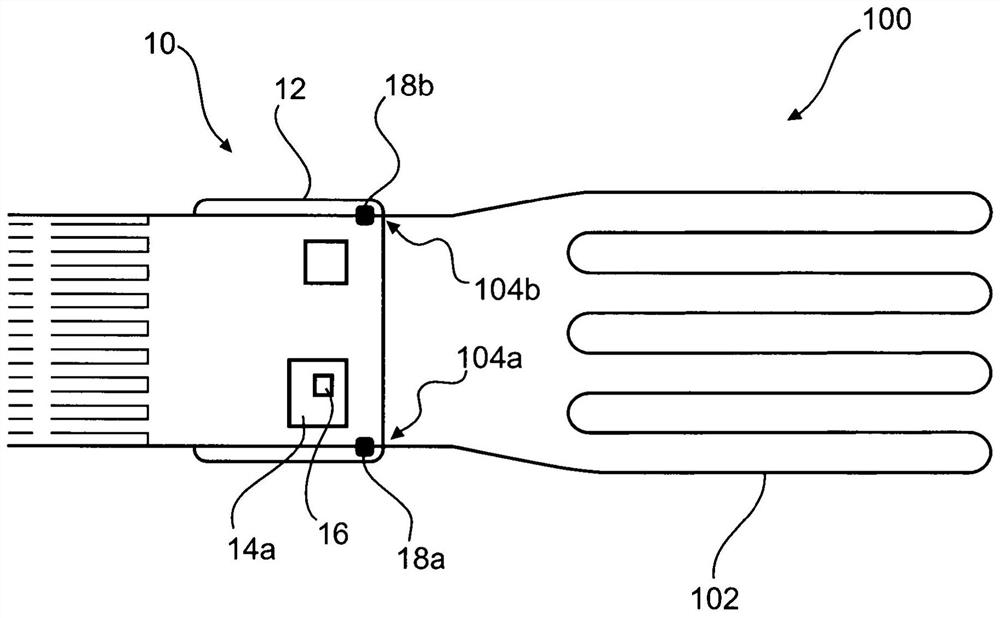

[0045] figure 1 and figure 2 The front side and the rear side of the circuit board 12 of the electronic control device 10 of the heating device 100 for a vehicle seat are shown.

[0046] A plurality of heat sources 14 a - 14 c are arranged on the circuit board 12 . Heat sources 14a-14c are integrated circuits, where heat source 14a is a microcontroller. The heat source 14b is a low-side driver (LS circuit), and the heat source 14c is a high-side driver (HS circuit).

[0047] Three temperature sensors 16 , 18 a , 18 b in the form of NTC resistors are arranged on printed circuit board 12 . The circuit board temperature sensor 16 is a component of the microcontroller 14 and is therefore thermally coupled to the microcontroller 14 a. Since the microcontroller 14a is disposed on the circuit board 12, the circuit board temperature sensor 16 is also thermally coupled to the heat source 14c.

[0048] The heating wire temperature sensors 18 a , 18 b are arranged in corner regions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com