Balancing clamp for screw tap tapping and using method of balancing clamp

A tap and balance technology, applied in manufacturing tools, metal processing equipment, tangent devices, etc., can solve the problems of time-consuming, labor-intensive, inability to expand and contract, and no quick clamping mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

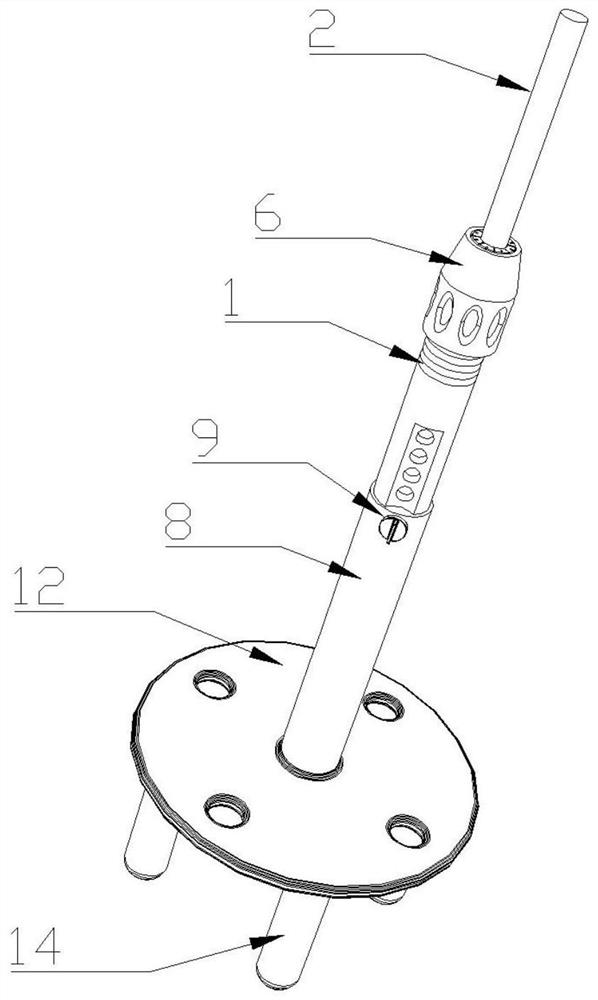

[0034] see Figure 1~4 , a balance fixture for tap tapping, comprising:

[0035] Connecting mechanism, it is by telescopic post 1 and fixed post 8, described telescopic post 1 that is used to connect fixed circular column structure is vertically connected and fixed on the top of fixed post 8, and the inside of described fixed post 8 is provided with a diameter larger than The cavity of the telescopic column 1, the telescopic column 1 is located in the cavity;

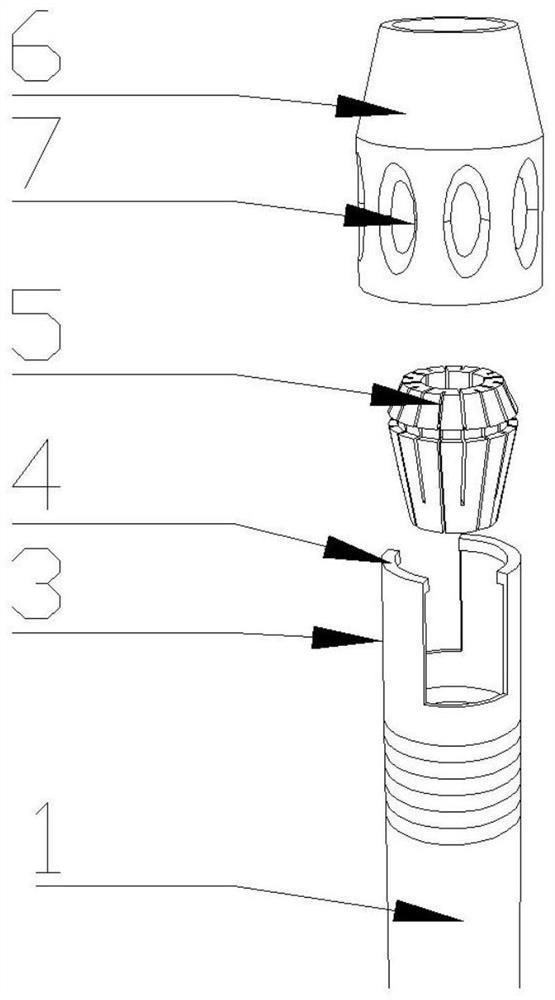

[0036] Clamping mechanism, it is made of ferrule 3 and lock sleeve 5, and described clamping mechanism is clamped and fixed on the top of connecting mechanism, and described ferrule 3 is vertically connected and fixed on the top of telescopic column 1, and described lock sleeve 5 The limit is clamped in the inner cavity of the ferrule 3 .

[0037] In the embodiment of the present invention, the top of the ferrule 3 is provided with an arc-shaped limiting clamp 4, and the center of the lock sleeve 5 is provided with an...

Embodiment 2

[0041] see Figure 1~4 , a balance fixture for tap tapping, comprising:

[0042] Connecting mechanism, it is by telescopic post 1 and fixed post 8, described telescopic post 1 that is used to connect fixed circular column structure is vertically connected and fixed on the top of fixed post 8, and the inside of described fixed post 8 is provided with a diameter larger than The cavity of the telescopic column 1, the telescopic column 1 is located in the cavity;

[0043] Clamping mechanism, it is made of ferrule 3 and lock sleeve 5, and described clamping mechanism is clamped and fixed on the top of connecting mechanism, and described ferrule 3 is vertically connected and fixed on the top of telescopic column 1, and described lock sleeve 5 The limit is clamped in the inner cavity of the ferrule 3 .

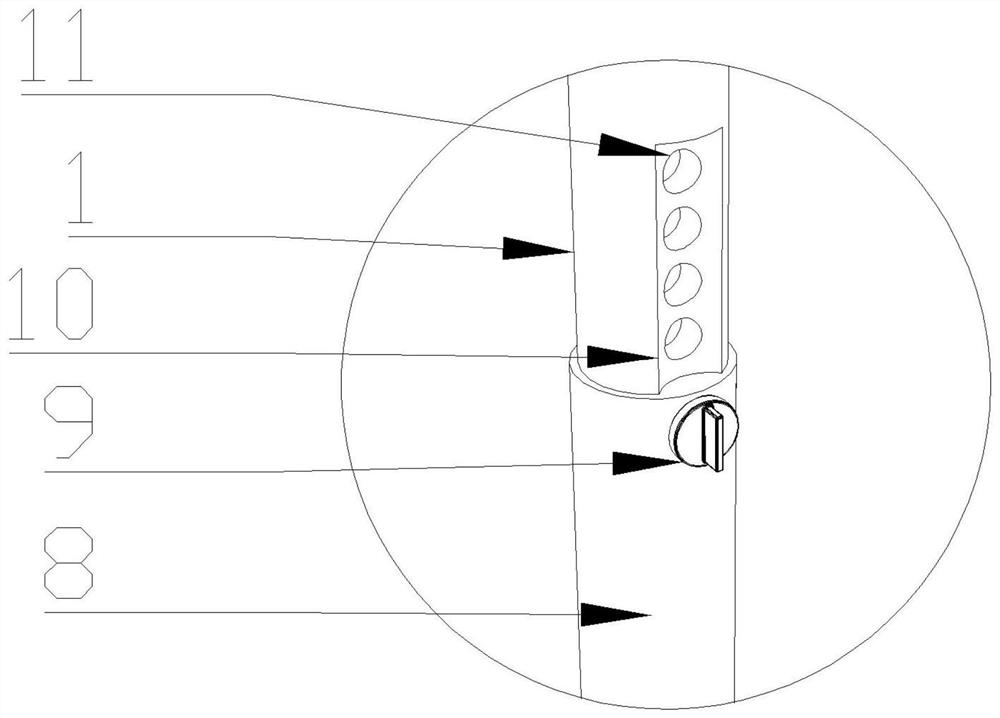

[0044] In the embodiment of the present invention, a limiting groove 10 is provided on the side wall of the telescopic column 1, the limiting groove 10 is arc-shaped, and positioni...

Embodiment 3

[0047] A method of using a balance fixture for tap tapping, the method of use is as follows:

[0048] 1) The fixed chassis 12 is positioned and docked with the machine tool through the positioning column 14;

[0049] 2) Then the fixed chassis 12 is connected and fixed with the machine tool through the fixing holes 13 by bolts;

[0050] 3) Then adjust the overall length between the telescopic column 1 and the fixed column 8 as required, and screw and lock the two through the adjusting screw 9 to form a unified whole;

[0051] 4) Then place the tap connection column 2 in the inner cavity of the lock sleeve 5, and adjust it to an appropriate length;

[0052] 5) After the adjustment is completed, screw the shrink sleeve 6 to shrink the lock sleeve 5, and then lock the tap connection column 2 and the telescopic column 1 to form a unified whole.

[0053] Working principle: When using the balance fixture, first connect the fixed chassis 12 with the machine tool through the fixing hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com