Novel fast-assembly type lamp structure

A fast-installed, lamp technology, applied in lampshades, lighting devices, fixed lighting devices, etc., can solve the problems of maintenance personnel slipping and falling, low maintenance and maintenance efficiency, etc., to achieve convenient and fast installation, improve installation efficiency and maintenance. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

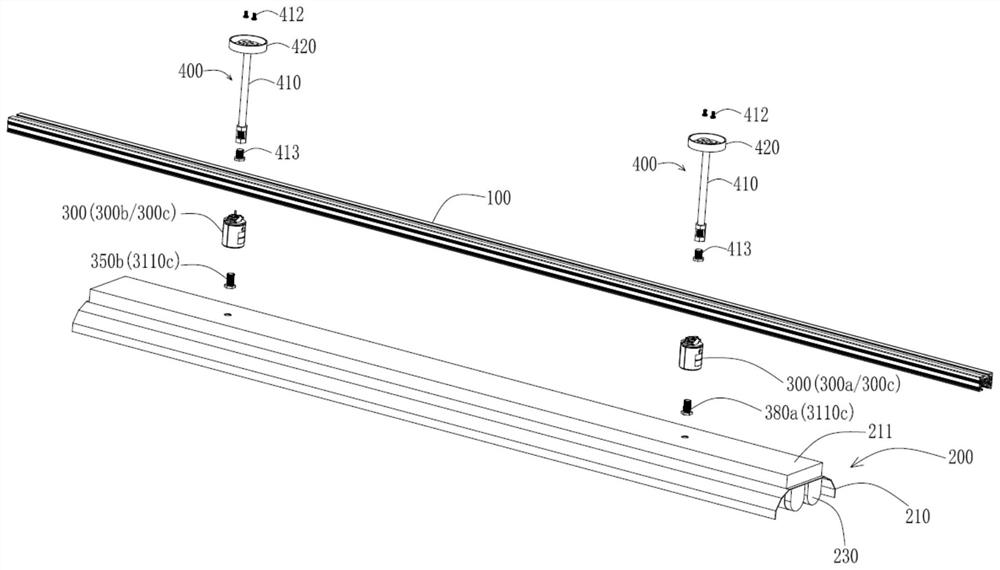

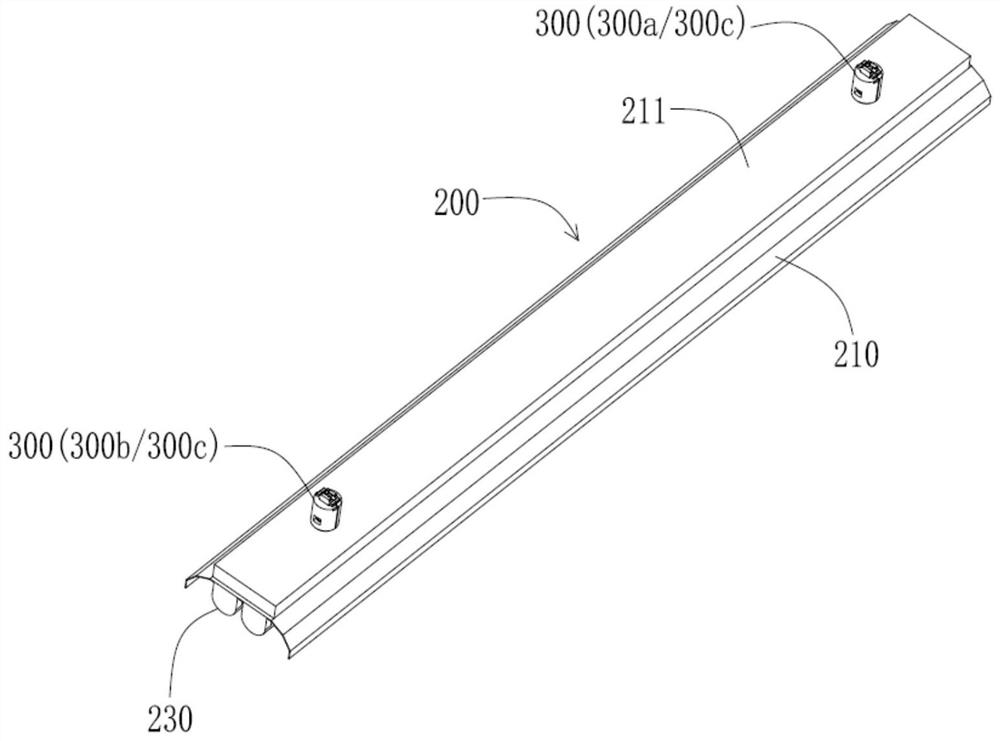

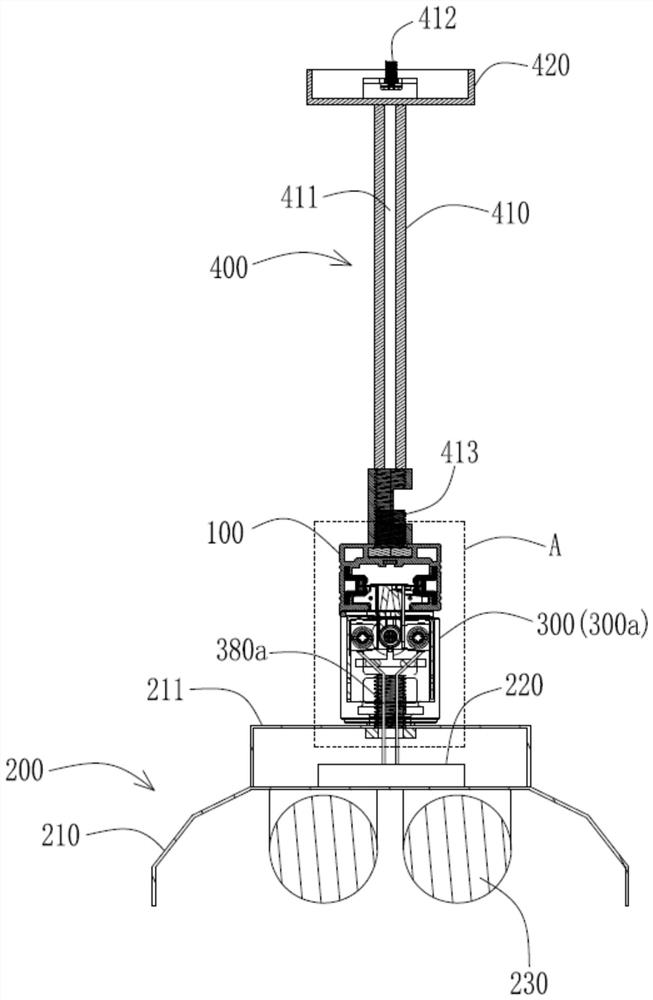

[0072] see Figure 1 to Figure 6 , shown in the figure is a new type of fast-installation lamp structure, including a conductive track 100, a lamp unit 200 and two quick conductive connectors 300.

[0073] The conductive track 100 is fixed on the ceiling through two sets of suspension rod assemblies 400 arranged at intervals along the length direction of the conductive track 100 . Of course, the number of guide rod assemblies 400 is not limited to the number in this embodiment, and they should be set according to the hoisting requirements of the conductive track 100 . Specifically, the boom assembly 400 includes a hollow boom 410 and a boom cover 420 . A cable channel 411 extending in the axial direction is formed in the hollow suspender 410. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap