A kind of garbage screening processing equipment

A processing equipment and screening technology, applied in grain processing, sieving, solid separation, etc., can solve the problems of poor screening ability and single function, and achieve the effect of strong screening ability, high cost performance, and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

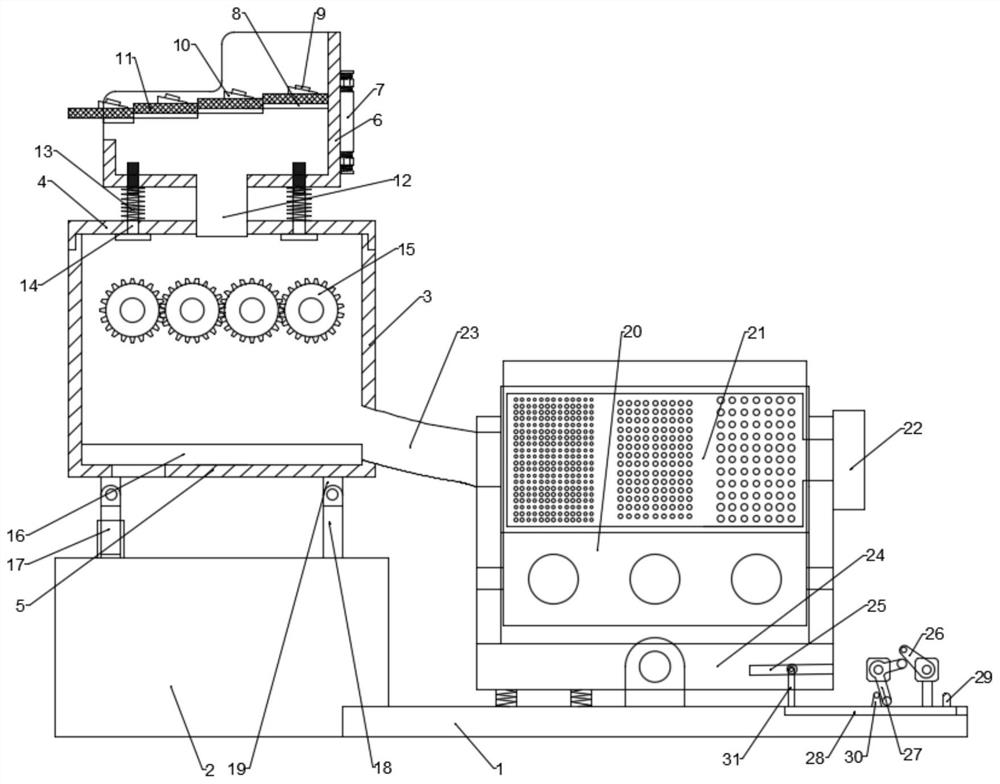

[0052] see figure 1 , in an embodiment of the present invention, a garbage screening treatment equipment, comprising:

[0053] Base body, the base body includes a high platform 2 and a first base 1, the height of the high platform 2 is greater than the height of the first base 1; one side of the high platform 2 is the garbage entry side, and the flow direction of the garbage is from the high platform 2 side to the second One side of the base 1, therefore, the height of the high platform 2 should be greater than the height of the first base 1, so that gravity becomes the driving force of the technical solution of the present invention.

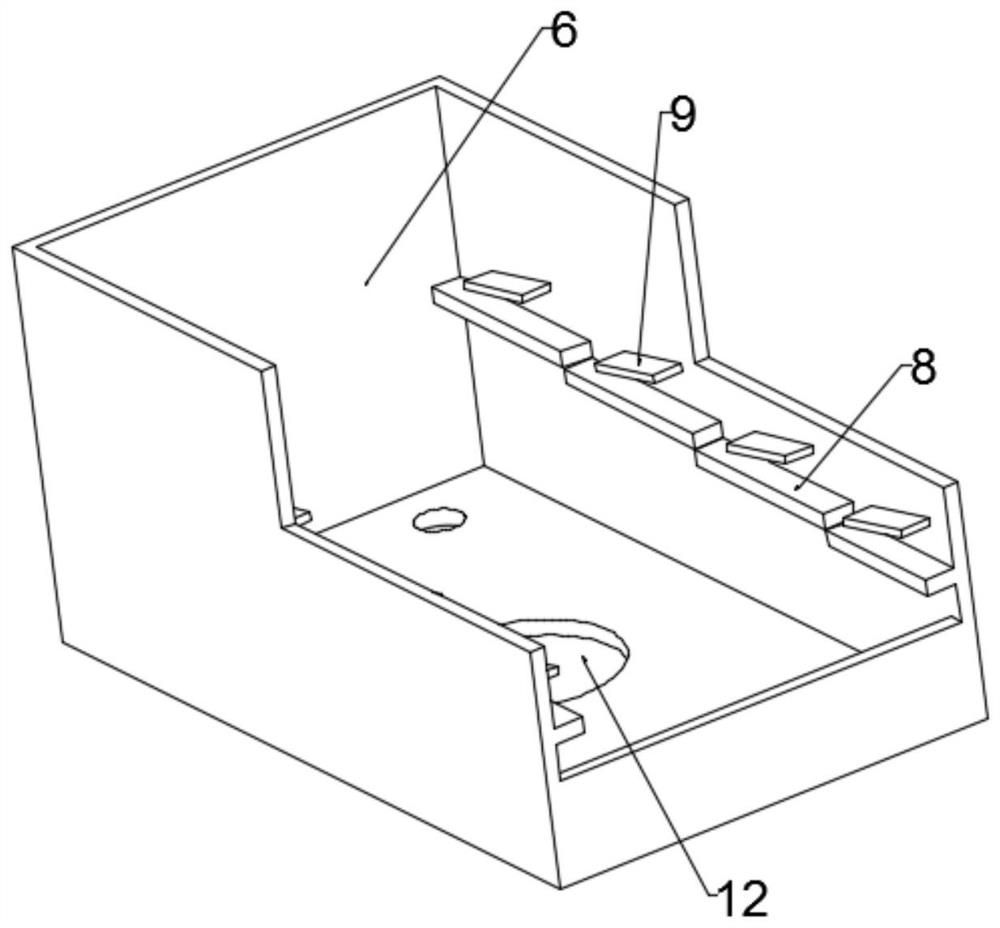

[0054] The feeding device arranged on the high platform 2, the feeding device includes a box body 3, the box body 3 is provided with a box cover 4 and a bottom plate 5; the box cover 4 is provided with a hierarchical filtering device, so The casing 3 is provided with a cleaning device 16 and a crushing wheel 15, and the crushing wheel 15 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com