Automatic portioning system for vacuum small-package products

A small packaging and product technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve problems such as error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is described in detail below. The embodiment of the present invention is only for illustrating the specific structure, and the scale of the structure is not limited by the embodiment.

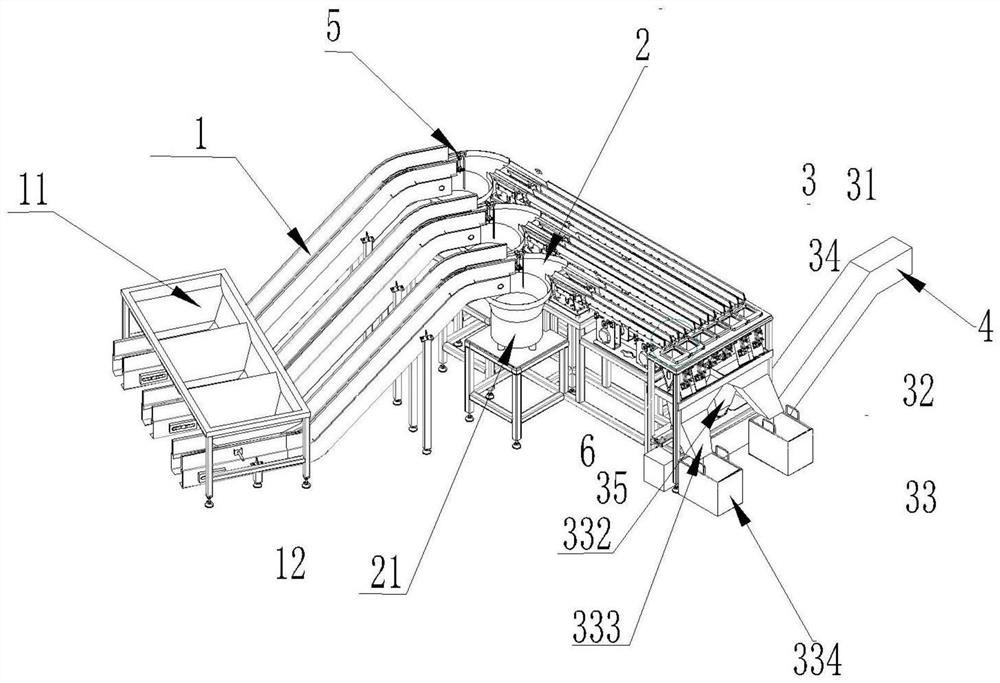

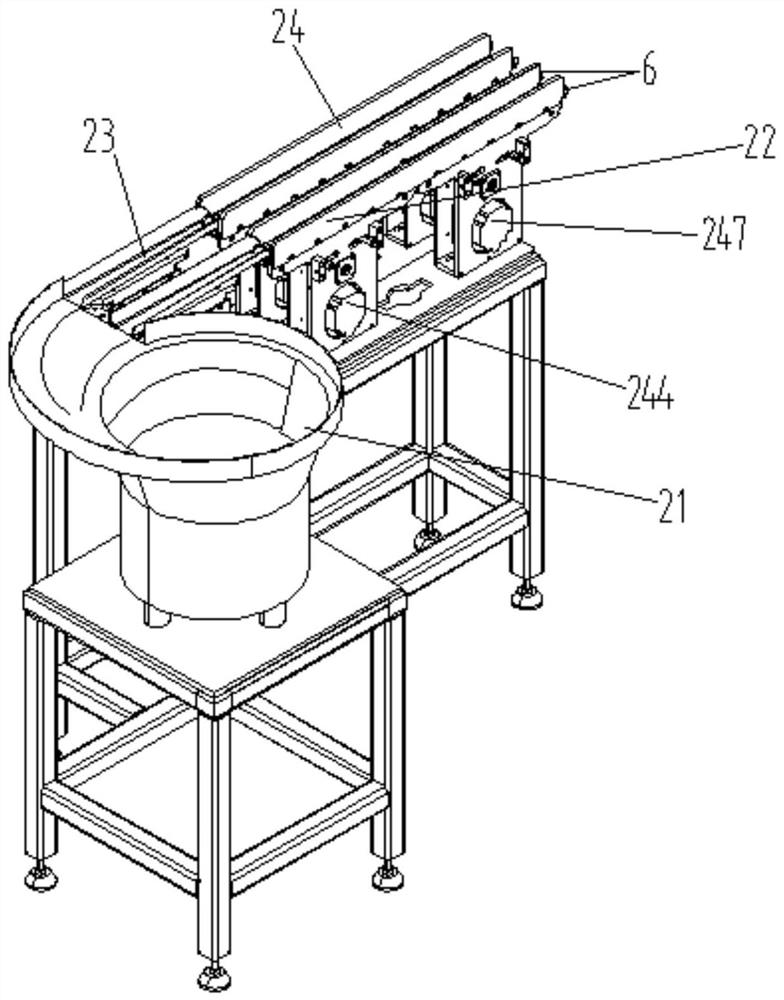

[0035] see Figure 1 to Figure 7 As shown, the automatic portioning system for small vacuum packaging products includes a feeding system 1, a material sorting and counting system 2, and a discharging and sorting system 3; the granular material passes through the feeding system 1 to the material sorting system 2, Finally, through the discharge and sorting system 3, it reaches the packaging and conveying system 4; the number of granular materials that come out is the required number of individual packaging.

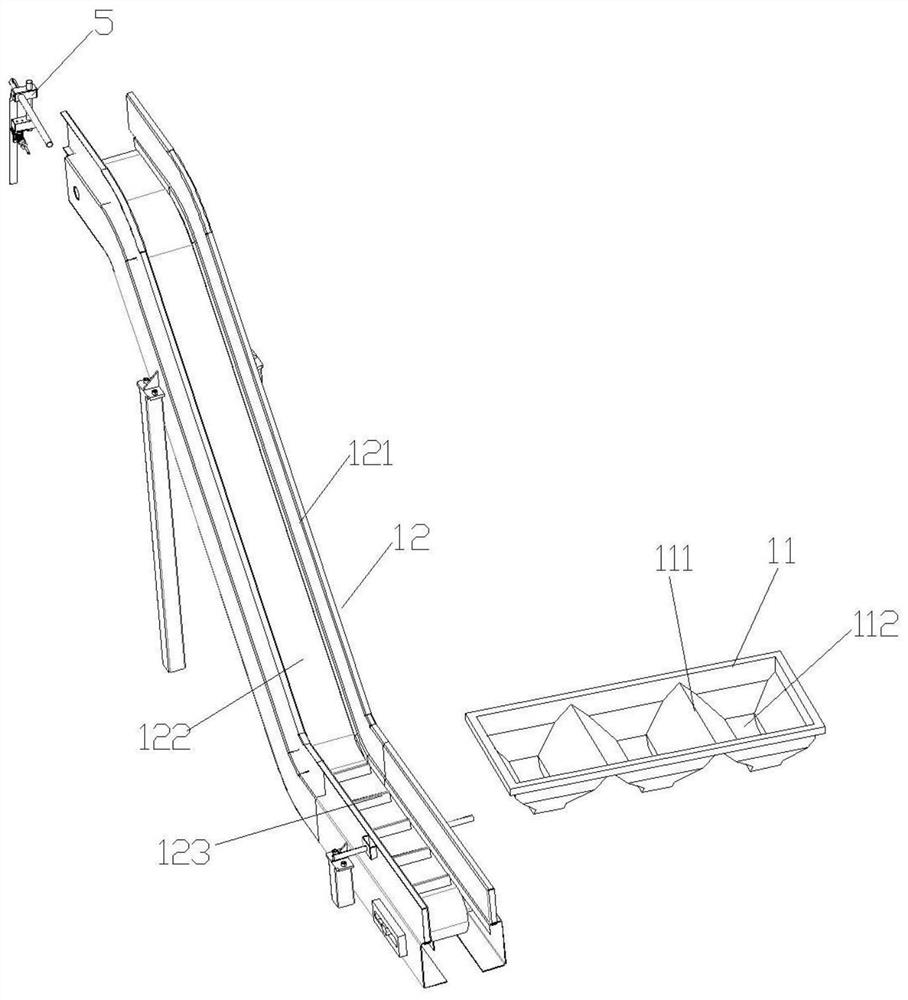

[0036] Feeding system 1 comprises feeding frame 11 and climbing feeding line 12; Each feeding frame 11 corresponds to a climbing feeding line 12; Feeding frame 11 is positioned at the top of climbing feeding line 12; Feeding frame 11 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com