High-efficiency casting production line

A production line and high-efficiency technology, applied to casting equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve problems such as low efficiency of pouring molten iron, and achieve the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

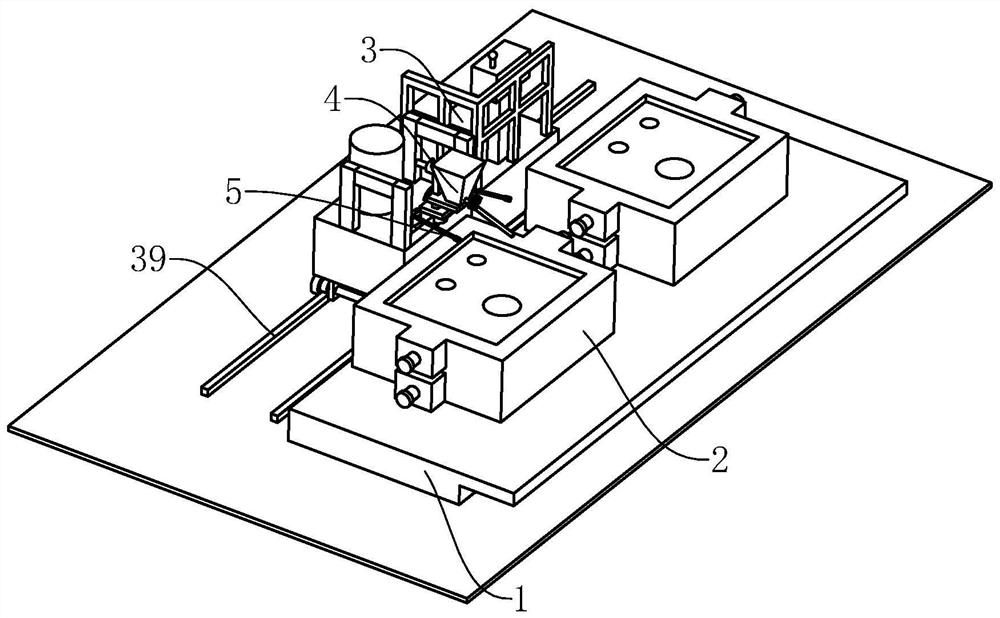

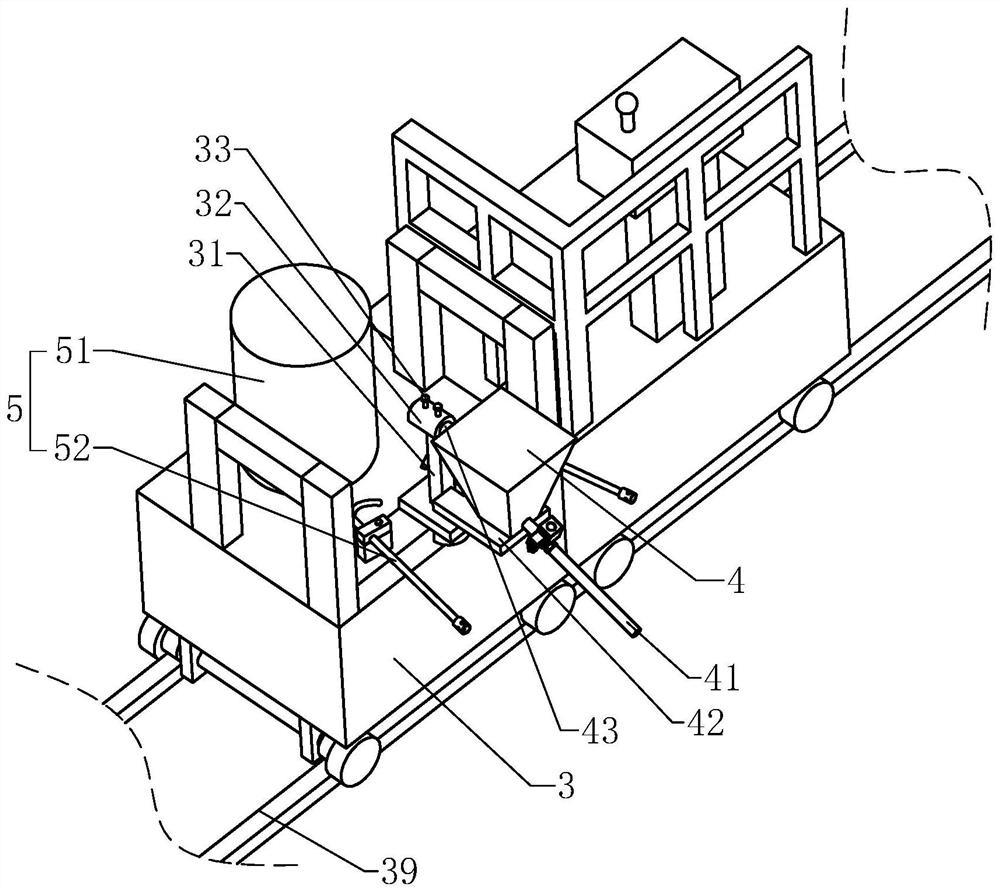

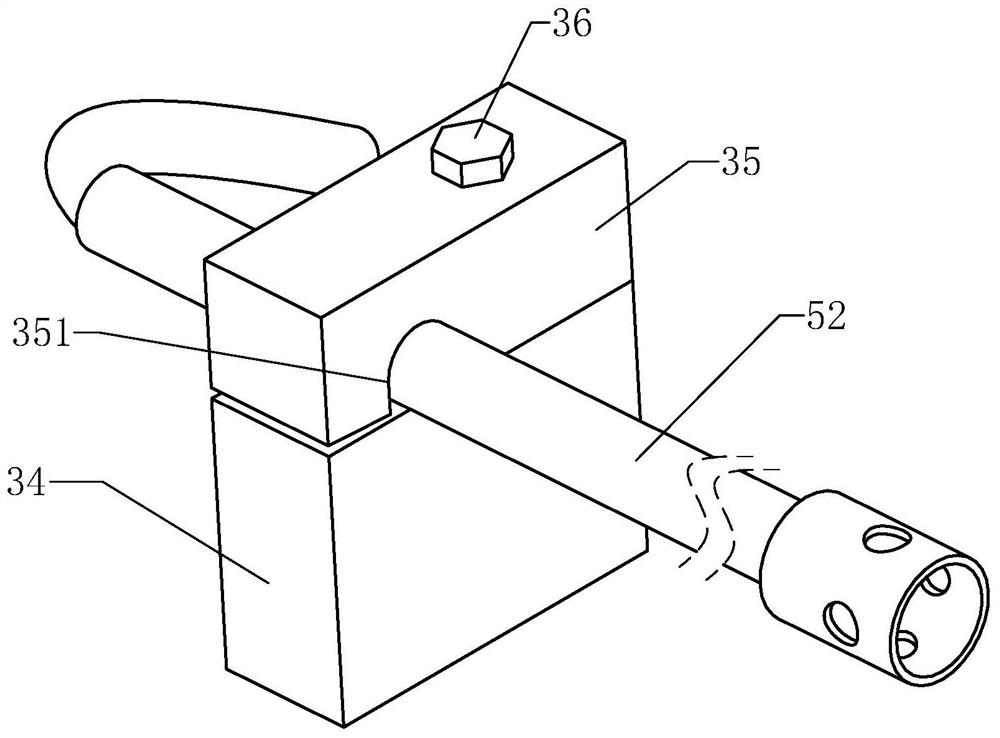

[0029] Such as figure 1 As shown, this embodiment introduces a high-efficiency casting production line, including a placement platform 1 and an operation platform 3, the placement platform 1 is placed above the ground, the operation platform 3 is located on one side of the placement platform 1, and the ground below the operation platform 3 A track 39 is fixedly arranged on the top, and the track 39 is parallel to the length direction of the placing table 1 , and the operating table 3 is slidably connected to the track 39 . A plurality of modules 2 are evenly spaced on the placing table 1, and each module 2 is a combination of the upper mold and the lower mold after the mold is closed. The ignition structure 5 is located above the placement table 1, and the filling hopper 4 is filled with the pre-casting agent. During the process of pouring the molten metal, the hopper 4 can add the pre-agent to the module 2 and the pre-agent is together with the molten metal. Enter the module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com