Crude oil treatment equipment for oil exploitation environment protection

A technology for environmental protection and oil extraction, which is applied in the directions of dehydration/demulsification by electricity/magnetism, dehydration/demulsification by chemical methods, etc. It can solve problems such as electrode plate corrosion, crude oil desalination work efficiency cannot be further improved, and crude oil content is large , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

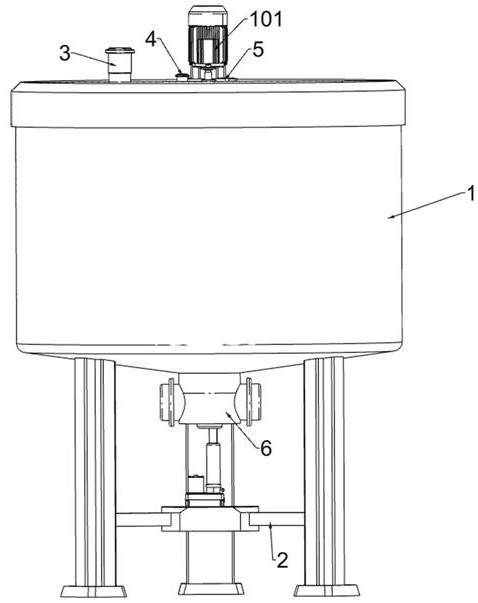

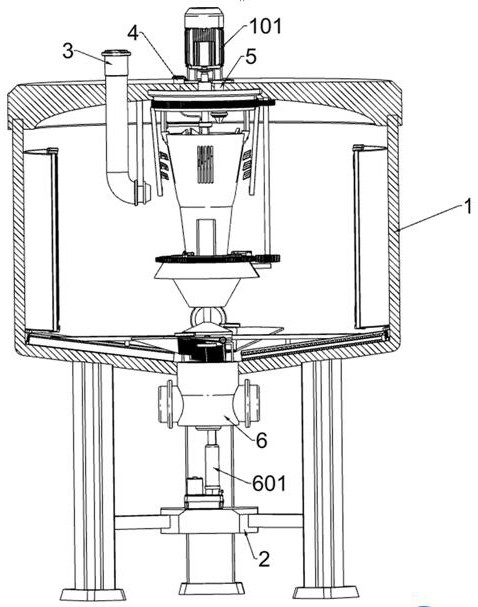

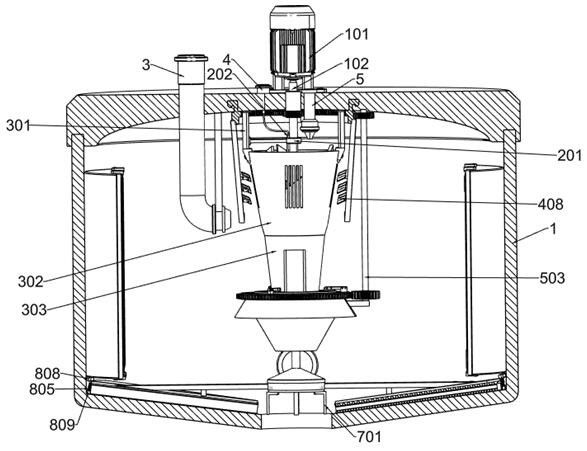

[0038] A kind of crude oil processing equipment for environmental protection of oil exploitation, such as Figure 1-Figure 4 As shown, it includes stirring assembly, milking and dilution assembly, central drainage assembly, auxiliary drainage assembly, cleaning assembly, bottom valve assembly, electrolysis chamber 1, fixing plate 2, oil delivery pipe 3, clean water pipe 4, demulsifier nozzle 5 and liquid outlet Pipe 6; the lower part of the electrolysis chamber 1 is fixedly connected with a fixed plate 2; the top plate of the electrolysis chamber 1 is connected with an oil delivery pipe 3; the top plate of the electrolysis chamber 1 is connected with a clean water pipe 4; The bottom plate of the electrolysis chamber 1 is connected with a liquid outlet pipe 6; the top plate of the electrolysis chamber 1 is connected with a stirring assembly; The top plate is bolted to the central drainage assembly; the left part of the whipping and dilution assembly is bolted to the central dra...

Embodiment 2

[0055] On the basis of Example 1, such as figure 2 and Figure 10-Figure 11 As shown, a rotating assembly is also included. The bottom plate of the electrolysis chamber 1 is provided with a rotating assembly. The rotating assembly includes a fourth fixed frame 701, a cover plate 702, a fifth spur gear 703, a sixth spur gear 704, and a third annular slide plate. 705 and the fourth gear ring 706; the bottom plate of the electrolysis cabin 1 is fixedly connected with the fourth fixing frame 701; the cover plate 702 is fixed on the upper surface of the third annular slide plate 705, and the internal parts are sealed to prevent corrosion. The lower end of the first rotating shaft 102 is rotationally connected with the fourth fixed frame 701; the lower end of the first rotating shaft 102 is fixedly connected with the fifth spur gear 703; the upper side of the fourth fixed frame 701 is connected with the sixth spur gear 704 through the rotating shaft; The spur gear 703 meshes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com