Clamping and feeding mechanism capable of moving in four directions and used for gear box machining

A gear box and square technology, applied in the direction of workpiece clamping devices, workbenches, manufacturing tools, etc., can solve problems such as inability to adjust, machine damage, singleness, etc., and achieve the effect of preventing the spread of sewage and improving the degree of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

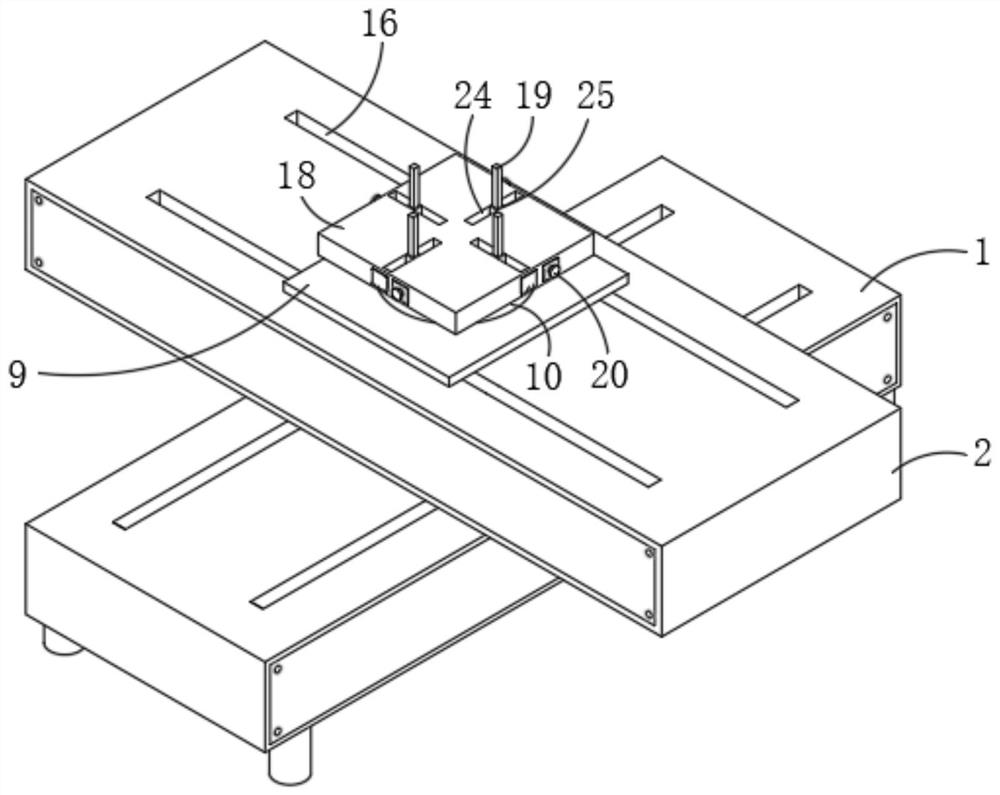

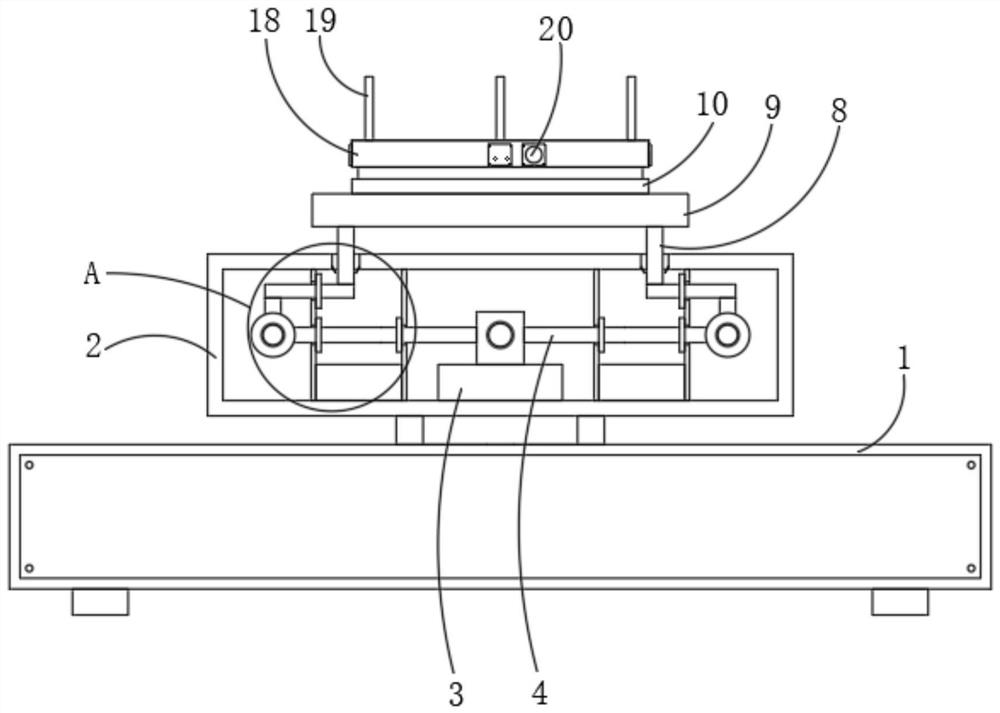

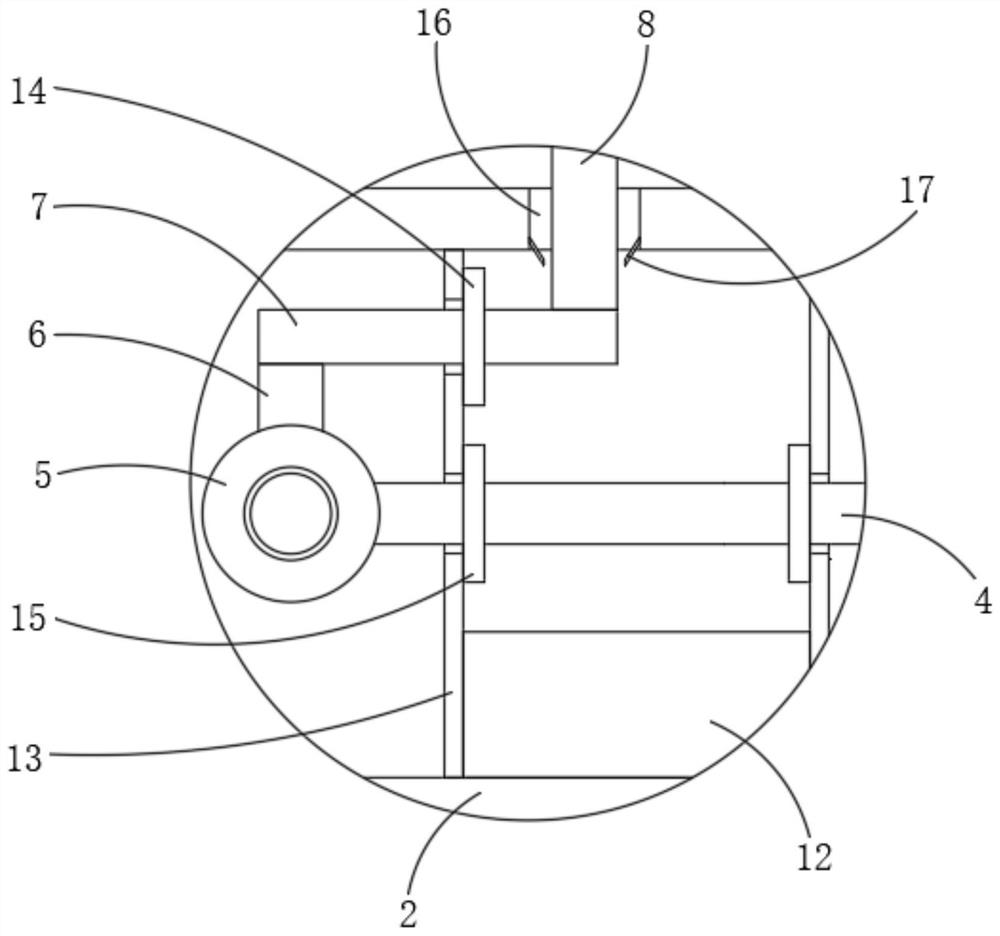

[0027] see Figure 1-3 , the present invention provides a technical solution: a four-way movable clamping and feeding mechanism for gear box processing, including a first shell 1 and a second shell 2, the first shell 1 and the second shell The inside of 2 is fixedly equipped with electric slide table 3, and both sides of the transmission end of electric slide table 3 are all fixedly installed with transmission rod 4, and the two ends of transmission rod 4 are all provided with ball screw 5 and are connected with the transmission end of ball screw 5. Rotationally connected, both ends of the ball screw 5 are bolted to the inner walls of the first housing 1 and the second housing 2 . By starting the electric sliding table 3, the transmission end of the electric sliding table 3 drives the transmission rod 4 to move, the transmission rod 4 drives the moving end of the ball screw 5 to move, and the moving end of the ball screw 5 drives the first connecting rod 6 and the second conne...

Embodiment 2

[0031] see figure 2 and image 3 , the difference between this embodiment 2 and embodiment 1 is:

[0032] The inner cavities of the first housing 1 and the second housing 2 are slidably connected with the collection box 12 between the ball screw 5 and the electric slide table 3, and the surface of the transmission rod 4 is located on both sides of the collection box 12. A baffle 13 is sleeved, and the inner side of the baffle 13 is slidably attached to the surface of the collection box 12 , and the top of the baffle 13 is respectively attached to the surfaces of the first casing 1 and the second casing 2 . By setting the baffle plate 13, the baffle plate 13 is used to cover both sides of the third through groove 16, to block the sewage entering through the third through groove 16, to prevent the sewage from spreading, and to affect the ball screw 5 and the electric slide table 3.

[0033] The top of the second housing 2 is provided with a third through groove 16 compatible...

Embodiment 3

[0038] see figure 1 , Figure 4 and Figure 5 , the difference between this embodiment 3 and embodiment 1 and embodiment 2 is:

[0039] The clamping mechanism 11 includes a plate body 18, and clamping rods 19 are slidably installed around the top of the plate body 18, and screw rods 20 are threaded around the plate body 18, and one end of the screw rod 20 extends to the inside of the plate body 18 and is threaded on the surface. Connected with a screw sleeve 21 , the side of the screw sleeve 21 close to the clamping rod 19 is fixedly mounted with a slanting rod 22 , and one end of the slanting rod 22 is connected to the clamping rod 19 in transmission. The inner cavity of the second chute 24 is provided with a connecting block 25, the top of the connecting block 25 is welded to the bottom of the clamping bar 19, and one end of the oblique bar 22 extends to the inner cavity of the second chute 24 and is welded to one side of the connecting block 25 .

[0040] The inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com