Robot debugging method for industrial automatic production

A technology of industrial automation and debugging methods, applied in the directions of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as single debugging, and achieve the effect of preventing sliding and overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

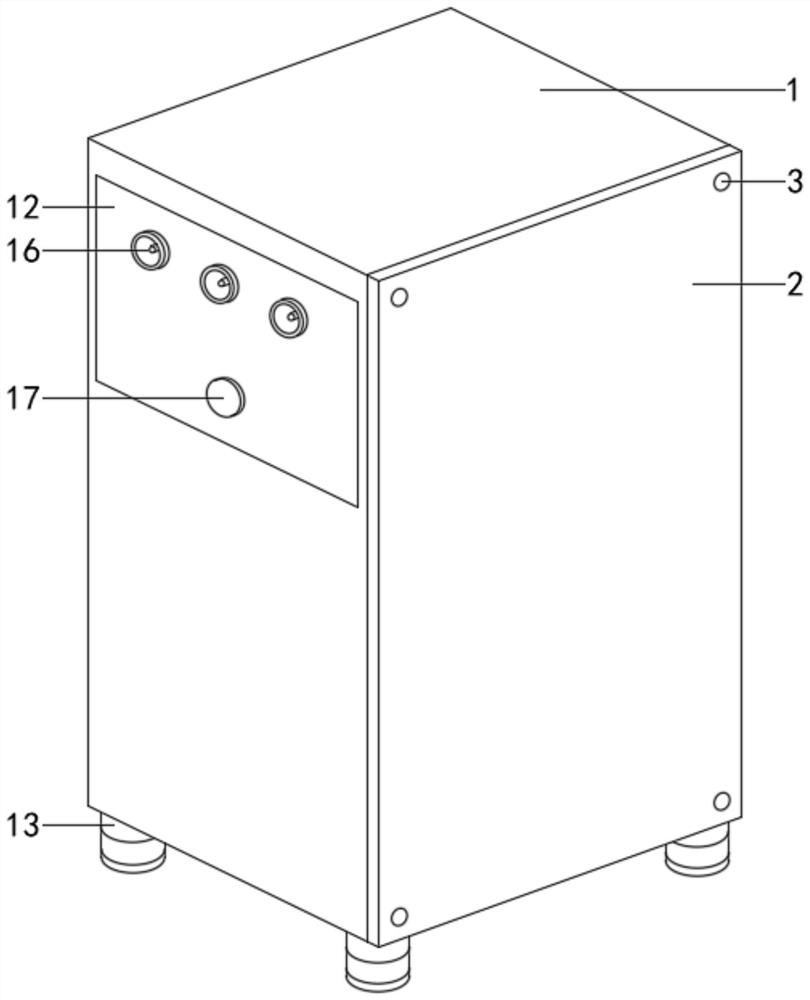

[0024] One end of the debugging device housing 1 is provided with a device side plate 2 , and one end of the device side plate 2 is screwed and connected with a fixing bolt 3 .

Embodiment 2

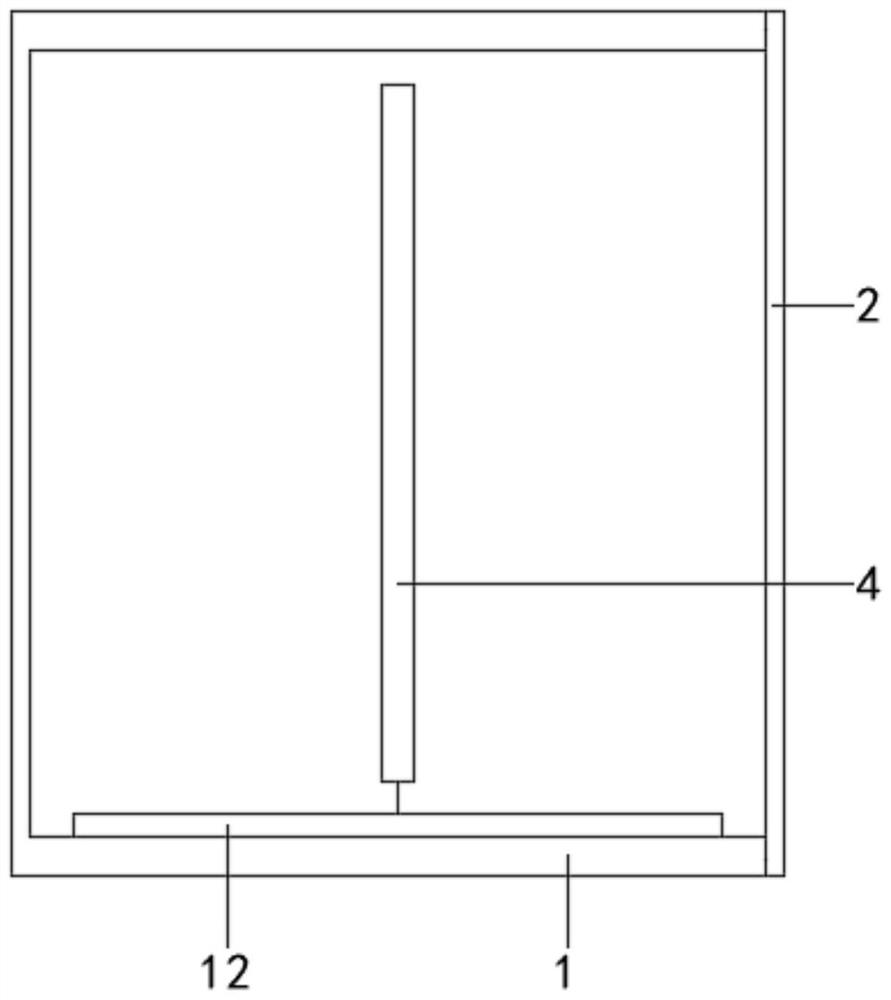

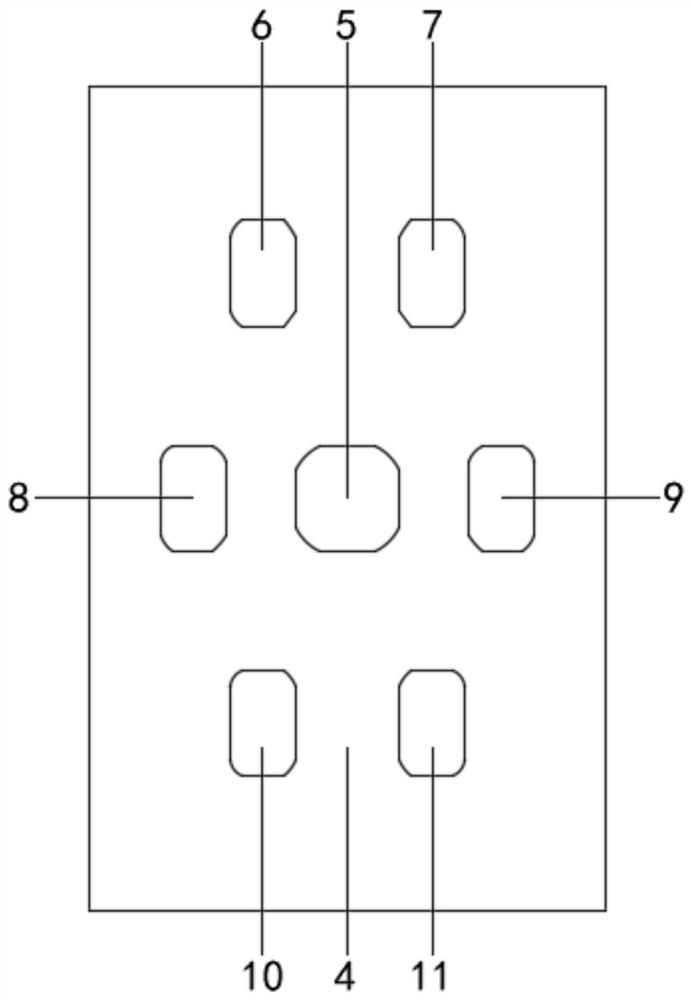

[0026] One end of the debugging device housing 1 is embedded with a control button board 12 , and the control button board 12 is electrically connected to the control circuit board 4 .

Embodiment 3

[0028] The bottom of the debugging device housing 1 is fixedly connected with a device support upper rod 13, and the bottom of the device support upper rod 13 is screwed and connected with a device support lower rod 14, and the bottom of the device support lower rod 14 is fixedly connected with a silicone non-slip bottom pad 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com