Detection device for edge and omnidirectional obstacle detection of cleaning equipment

A technology for cleaning equipment and detection devices, which is applied in the direction of cleaning equipment, cleaning devices, robot cleaning machines, etc., and can solve the problems of high module cost, reducing labor intensity and danger of manual glass cleaning, and insensitive frame detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

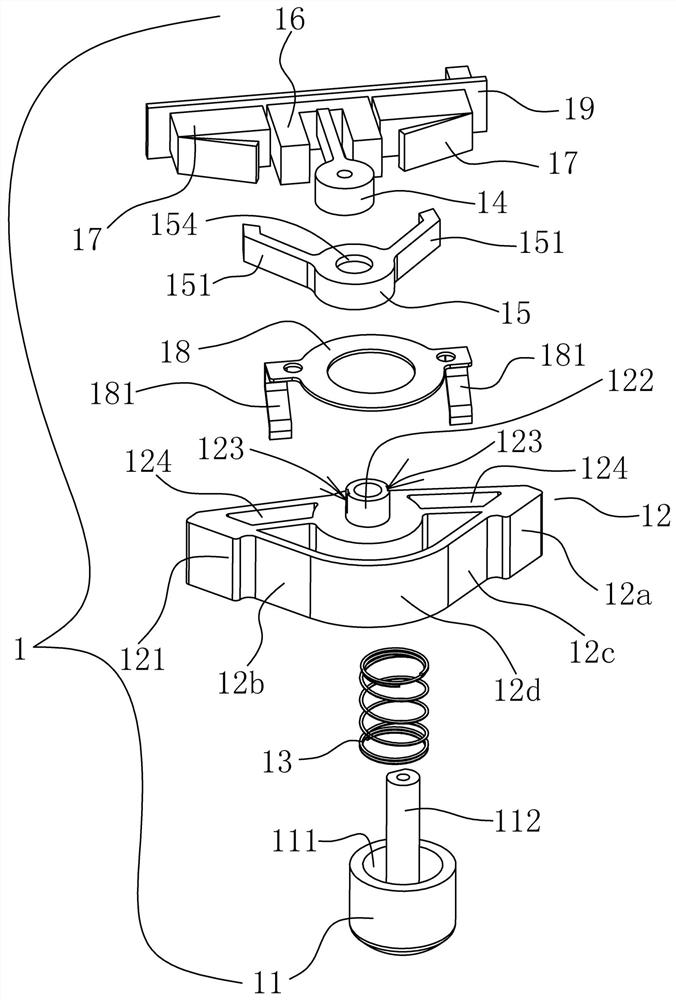

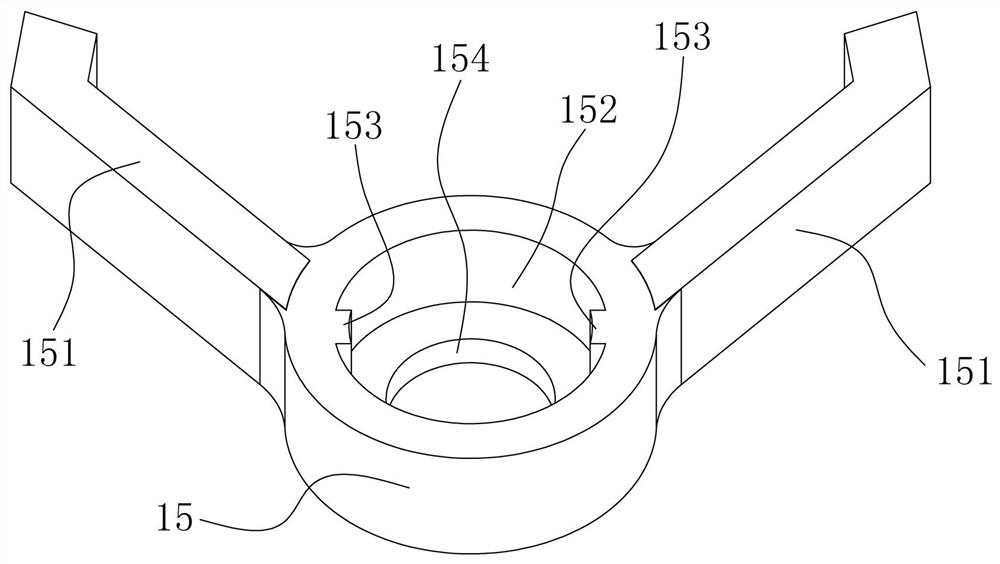

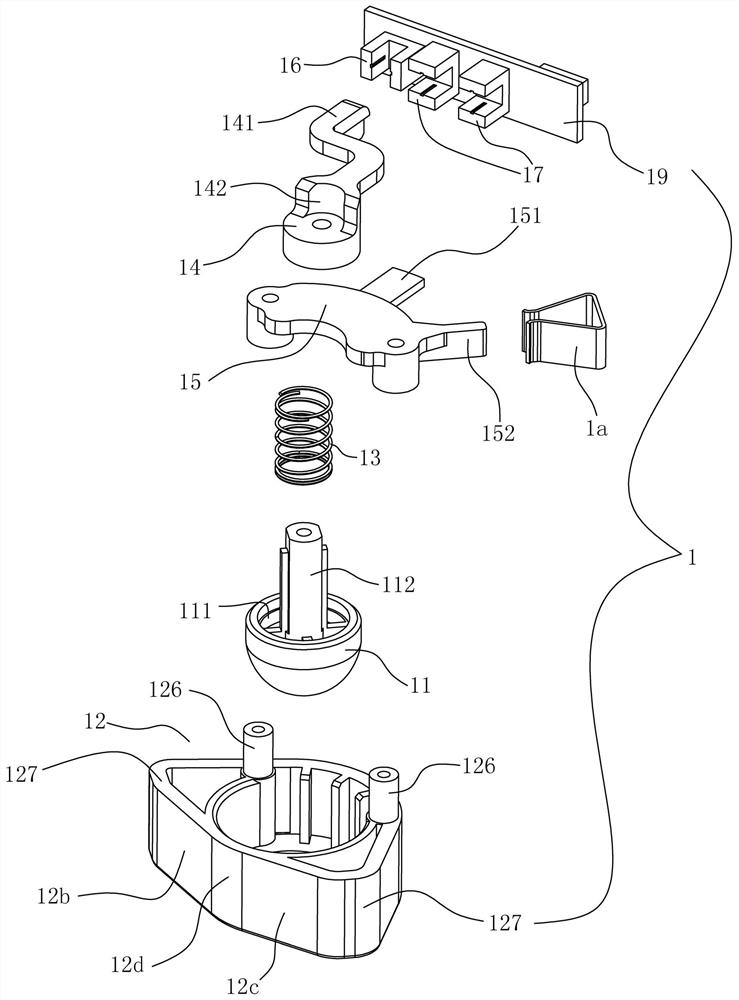

[0030] like Figure 1-11 As shown, the present invention relates to a detection device 1 for edge and omnidirectional obstacle detection of cleaning equipment. The cleaning equipment has a built-in main control unit 6. The detection device 1 includes an edge lifting part 11, which is located on the edge lifting part 11. Collision block 12 below, reset spring 13 sleeved on the edge lifting part 11, edge sensing block 14 on the upper end of the edge lifting part 11, edge sensing part 16 on one end of the edge sensing block 14, and collision block 12 The connected obstacle sensing block 15 and the obstacle sensing part 17 provided corresponding to the obstacle sensing block 15, the collision block 12 is used to drive the obstacle sensing block 15 to trigger the corresponding obstacle sensing part 17 when one side of the cleaning device encounters an obstacle, the edge The sensing part 16 is used to cooperate with the return spring 13 and the edge sensing block 14 to judge whether...

specific Embodiment 2

[0042] like image 3 , 4 As shown, the present invention discloses a detection device used for edge and omnidirectional obstacle detection of cleaning equipment, and the two sides of the collision block 12 are respectively provided with collision protrusions 127, and the collision protrusions 127 are used for cleaning devices. When one side encounters an obstacle, it drives the collision block 12 to rotate towards the opposite direction of the obstacle. One side of one collision protrusion 127 is provided with a front linkage part 12b, and the other collision protrusion 127 is provided with a side linkage part 12c at one time. An oblique linkage part 12d is also provided between the front linkage part 12b and the side linkage part 12c; specifically, each collision protrusion 127 can be used independently, wherein one collision protrusion 127 is used in combination with the front linkage part 12b, and the other Collision protrusion 127 and side linkage part 12c are used in com...

specific Embodiment 3

[0050] like Figure 4 , 5 As shown, the present invention discloses a detection device for edge and omnidirectional obstacle detection of cleaning equipment. One side of the edge lifting part 11 forms a built-in groove 111, and a mounting column 112 is protruded from the built-in groove 111. The spring 13 is sleeved on the mounting column 112 and placed in the built-in groove 111; each corner of the base 51 is respectively provided with movable sleeves (not shown), and each edge lifting part 11 is respectively installed in the movable sleeves, Each collision block 12 is respectively arranged on one side of the movable sleeve; the edge sensing part 16 and the obstacle sensing part 17 are respectively mounted on the same detection circuit board (not shown), the detection circuit board is fixedly connected with the base 51, and the edge sensing The portion 16 and the obstacle sensing portion 17 preferably adopt photoelectric switches respectively, and trigger the edge sensing po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com